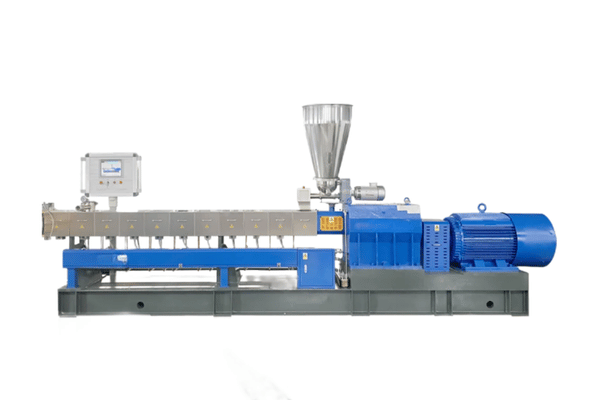

Advanced Plastic Sheet Extrusion Line for High-Volume, Precision Production

The Plastic Sheet Extrusion Line is the ideal solution for manufacturers looking to produce high-quality plastic sheets with consistency, speed, and minimal waste. Engineered for heavy-duty use and long production runs, this line enables seamless production of sheets made from materials like PP, PS, PET, PVC, and ABS. Whether you’re serving packaging, construction, automotive, or appliance sectors, this machine delivers the control and flexibility needed to meet a wide range of industrial requirements.

With growing global demand for customized, lightweight, and recyclable plastic sheets, investing in an efficient sheet extrusion system is more critical than ever. This machine’s intelligent temperature management, precise thickness control, and modular configuration ensure uniform product quality across various sheet widths and thicknesses. Stay ahead of market demands with a proven, scalable solution that enhances both productivity and profitability.

Key Features of Plastic Sheet Extrusion Line

- Compatible with multiple materials including PP, PET, PS, PVC, ABS

- Precision T-die for consistent sheet thickness and smooth surface

- PLC-based automatic control system with real-time data monitoring

- Energy-efficient heating and cooling systems

- Calendering system for sheet surface control and finish

- Customizable width and thickness options

- Easy mold changes and maintenance access

Applications and Uses

- Food packaging trays and containers

- Thermoforming and vacuum forming

- Refrigerator and appliance liner sheets

- Automotive interior and decorative panels

- Stationery, folders, and protective sheets

- Building insulation panels

Product Benefits

- Uniform thickness and high surface clarity

- Low scrap rate and energy consumption

- Adaptability to different resin formulations

- Modular setup for easy upgrades or material changes

- High-speed production with reduced downtime

Technical Specifications

| Specification | Details |

|---|---|

| Applicable Materials | PP, PS, PET, PVC, ABS |

| Sheet Width Range | 600mm – 2100mm |

| Thickness Range | 0.2mm – 6mm |

| Extrusion Output Capacity | Up to 800 kg/h depending on configuration |

| Extruder Type | Single or twin-screw extruder |

| Control System | PLC with HMI touchscreen |

| Heating Zones | 4 – 8 zones with PID control |

| Cooling Method | Water cooling + air knife |

| Calender Rollers | 3-Roll or 5-Roll system |

| Drive Motor Power | 45 – 132 kW |

| Certification | CE Certified, ISO Compliant |

Why Choose MT Royal?

Choosing MT Royal means working with a partner that combines global trade expertise and technical know-how

- 18 years of experience in exporting industrial machinery

- Fast and secure shipping from Mersin and Istanbul warehouses

- Legally registered in Turkey and member of Istanbul Chamber of Commerce

- All required documentation and certificates for customs clearance provided

- Flexible payment options via banks and currency exchange platforms

- Free expert consultation to help select the best extrusion system

- Competitive pricing backed by a strict quality guarantee

Conclusion and Summary

The Plastic Sheet Extrusion Line stands as one of the most sought-after and high-quality systems in the plastic manufacturing industry, offering precise and efficient sheet production for a wide range of applications. With rising demand for recyclable and thermoformable plastic sheets, this production line is ideal for packaging, construction, and appliance industries.

Equipped with a precision T-die, automated PLC control, and a modular calendering system, this line ensures consistent sheet thickness, superior surface finish, and minimal material waste. It supports multiple polymers such as PP, PS, PET, PVC, and ABS, and can be customized to handle various sheet widths and thicknesses. The energy-efficient heating and cooling systems further reduce operational costs while boosting productivity.

MT Royal, with over 18 years of experience, is a trusted supplier of industrial machinery and equipment. We ship quickly from warehouses in Mersin and Istanbul, provide all customs documentation and certificates, and offer secure payment options. As a registered Turkish company and member of the Istanbul Chamber of Commerce, we are committed to reliability and transparency.

Upgrade your manufacturing line with a proven, high-efficiency solution. Contact MT Royal today for expert consultation, competitive pricing, and a complete plastic sheet extrusion system tailored to your needs.

Reviews

There are no reviews yet.