In the dynamic world of plastic manufacturing, achieving optimal product performance and production efficiency is paramount. One common challenge, particularly in film extrusion, is the phenomenon of “blocking,” where layers of plastic film adhere to one another, causing significant operational disruptions and compromising product quality. To counteract this, anti-block masterbatches play a crucial role. These specialized additives are designed to prevent adhesion, ensuring smooth processing and handling of films. When it comes to sourcing these vital compounds, finding a reliable Anti-block Masterbatch Supplier is essential. MT Royal has emerged as a key player in this sector, consistently providing high-quality solutions that address the specific needs of various industries. As a leading PVC Masterbatch Supplier, MT Royal’s commitment to innovation and quality ensures that their clients receive products that enhance productivity and end-product performance.

Introducing Anti-block Masterbatch Solutions

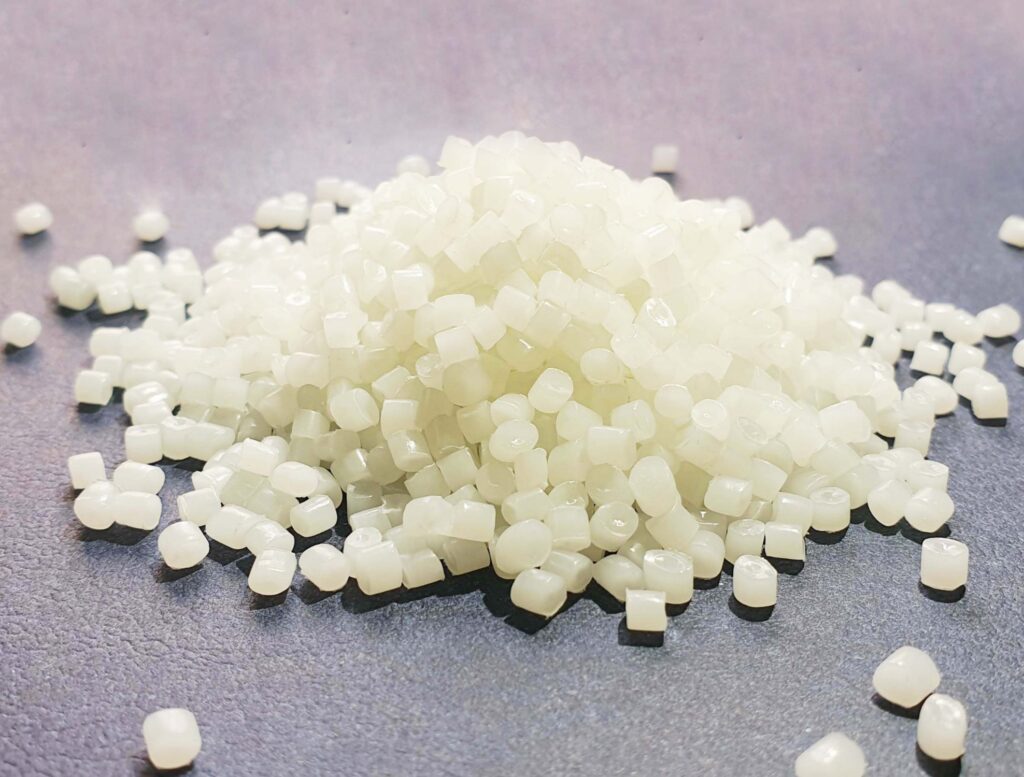

Anti-block masterbatches are formulations of finely dispersed inorganic or organic particles in a polymer carrier. These particles create a microscopic roughness on the surface of the plastic film, which reduces the contact area between film layers. This reduction in contact area effectively minimizes the attractive forces that lead to blocking. The choice of anti-block agent, its particle size, and concentration are critical factors that influence the effectiveness of the masterbatch. Different applications require different types of anti-block agents, such as synthetic silicas, talc, or calcium carbonate, each offering unique properties in terms of clarity, slip, and anti-blocking performance. MT Royal specializes in developing and supplying a comprehensive range of these masterbatches, meticulously engineered to meet diverse film requirements. Their products are designed to integrate seamlessly into existing production lines, ensuring a smooth transition and immediate benefits in terms of process efficiency.

Advantages of Using Anti-block Masterbatches

The advantages of incorporating anti-block masterbatches into film production are numerous and directly impact both manufacturing efficiency and product quality. Firstly, they significantly improve the processability of plastic films. Without anti-block agents, films can stick together, leading to difficulties in unwinding rolls, higher friction, and increased downtime due to machine jams. This translates into reduced production speeds and higher operational costs. Secondly, anti-block masterbatches enhance the overall quality of the final product. Films treated with these additives exhibit better handling characteristics, making them easier to cut, stack, and process further. This is particularly important for packaging applications where high-speed automated machinery is used. Furthermore, these masterbatches can improve the optical properties of the film, such as clarity and haze, depending on the type and concentration of the anti-block agent used. MT Royal’s anti-block masterbatches are developed to deliver consistent performance, offering reliable solutions that help manufacturers achieve superior film quality and operational excellence. Their expertise as a PVC Masterbatch Supplier ensures that even specialized applications receive tailored solutions.

Product Specifications

When considering anti-block masterbatches, several key specifications define their performance and suitability for specific applications. These include the carrier resin, the type and concentration of the anti-block agent, particle size distribution, and the physical form of the masterbatch. The carrier resin should be compatible with the polymer being processed to ensure proper dispersion and adhesion. Common carrier resins include polyethylene (PE), polypropylene (PP), and ethylene-vinyl acetate (EVA). The anti-block agent itself can be natural minerals like talc or diatomaceous earth, or synthetic materials such as silica. The particle size and morphology of these agents are crucial, as they determine the level of surface roughness and the optical properties of the film. Finer particles typically result in lower haze and better transparency, while coarser particles provide more aggressive anti-blocking. Concentration of the active ingredient directly impacts the dosage required and the overall cost-effectiveness. MT Royal offers a diverse portfolio of anti-block masterbatches, with a wide range of specifications to cater to various film types, including those requiring high transparency or specific friction coefficients. Their product development team works closely with clients to tailor solutions that precisely match their technical requirements.

Applications of Anti-block Masterbatches

The versatility of anti-block masterbatches makes them indispensable across a wide spectrum of industries, particularly those involved in film manufacturing. In the packaging sector, they are crucial for producing films used in food packaging, industrial wraps, and shrink films, where smooth unwinding and efficient processing are vital for high-speed automated lines. Agricultural films, such as greenhouse covers and mulching films, also benefit significantly from anti-block properties, preventing layers from sticking together during storage and deployment. In the medical field, sterile packaging often relies on these masterbatches to ensure ease of opening and handling. Beyond these, anti-block masterbatches are widely used in the production of stretch films, protective films, and lamination films. Each application has unique demands regarding film clarity, slip properties, and mechanical strength, all of which can be fine-tuned by selecting the appropriate anti-block masterbatch. As a reputable Anti-block Masterbatch Supplier, MT Royal provides specialized formulations that cater to these diverse applications, ensuring optimal performance across various film types and processing conditions. Their commitment to innovation allows them to support new and emerging applications within the plastics industry.

Purchasing from MT Royal

When seeking a reliable Anti-block Masterbatch Supplier, look no further than MT Royal. The company stands out due to its unwavering commitment to quality, extensive product range, and exceptional customer service. MT Royal understands the intricate demands of the plastics industry and offers tailor-made solutions to meet specific client needs. Their anti-block masterbatches are manufactured using advanced techniques and high-grade raw materials, ensuring consistent quality and superior performance. As a prominent PVC Masterbatch Supplier, their expertise extends across various polymer types, providing comprehensive solutions. Clients benefit from MT Royal’s technical support team, who can assist in selecting the most suitable masterbatch for their application, optimizing dosage, and troubleshooting any processing challenges. The procurement process with MT Royal is streamlined and efficient, ensuring timely delivery and competitive pricing. Their dedication to fostering long-term partnerships is evident in their flexible approach and responsiveness to market demands. Choosing MT Royal means partnering with a company that prioritizes your production efficiency and product quality.

Conclusion

Anti-block masterbatches are fundamental to the efficient and high-quality production of plastic films. They address a critical challenge in film processing, ensuring smooth operations, reducing waste, and enhancing the overall value of the end product. The choice of a reliable Anti-block Masterbatch Supplier is therefore paramount for any manufacturer looking to optimize their film production processes. MT Royal has firmly established itself as a leader in this field, offering an extensive array of high-performance anti-block solutions tailored to diverse industrial needs. Their commitment to quality, technical expertise, and customer-centric approach positions them as an invaluable partner for businesses across the plastics industry. As a key PVC Masterbatch Supplier, MT Royal continues to drive innovation, providing advanced masterbatch solutions that contribute to improved productivity and superior film characteristics. By partnering with MT Royal, manufacturers can ensure their films meet the highest standards of quality and performance, ultimately enhancing their competitive edge in the market.

Reviews

There are no reviews yet.