The global plastics industry relies on a consistent supply of high-quality raw materials. Among these, polyethylene terephthalate (PET) chips stand out as a cornerstone for producing a vast array of products, particularly plastic bottles and containers. The blow molding process, which shapes these materials into their final form, demands specialized PET chips with specific properties like high clarity, strength, and thermal stability. Finding a reliable Polyplex PET Chips for Blow Molding Use supplier is crucial for manufacturers to ensure production efficiency and product quality. MT Royal, a name synonymous with excellence in the Plastic Raw Materials sector, has established itself as a premier source for these vital materials. We pride ourselves on providing products that not only meet but exceed industry standards, helping our clients achieve their manufacturing goals.

Understanding the Product

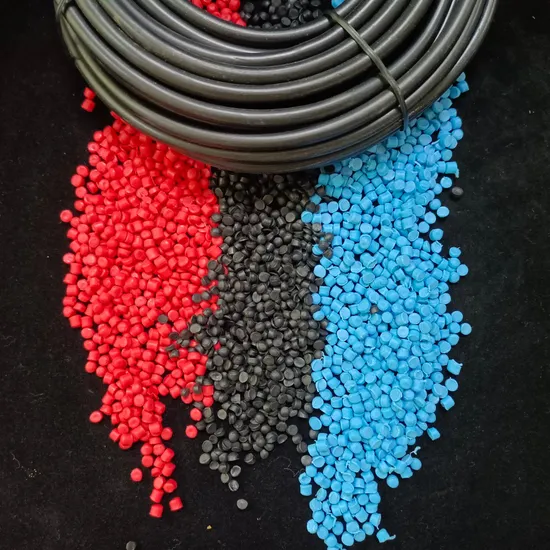

Polyplex PET Chips for Blow Molding Use are a specialized grade of PET resin. Unlike general-purpose PET, these chips are optimized for the high-speed and demanding nature of the blow molding process. This process involves heating the PET chips until they become molten, then molding them into a preform which is subsequently stretched and inflated into the final bottle shape. The quality of the PET chips directly influences the clarity, strength, and finish of the end product. High-grade chips, such as those supplied by MT Royal, ensure minimal defects and a consistent, high-quality output. These specialized chips fall under the broader category of Plastic Raw Materials, but their unique properties set them apart.

Key Advantages of Polyplex PET Chips

One of the primary benefits of using high-quality Polyplex PET chips is the superior clarity and finish they impart to the final product. Bottles made from these chips are clear, shiny, and free of imperfections. Another significant advantage is their excellent mechanical properties. This includes high tensile strength and impact resistance, which are essential for durable and safe containers. Furthermore, the thermal stability of these chips allows for a wider processing window during blow molding, reducing machine downtime and improving overall efficiency. This stability is a key feature of the products supplied by MT Royal. Our chips are also known for their low acetaldehyde (AA) content, which is a critical factor for food and beverage packaging as it prevents any undesirable taste or odor transfer.

Technical Specifications

The technical specifications of Polyplex PET chips are what make them suitable for blow molding. These include intrinsic viscosity (IV), which measures the molecular weight of the polymer and affects its mechanical properties and processability. The ideal IV range for blow molding is carefully maintained by suppliers like MT Royal. Another important spec is melting point. Our PET chips have a consistent melting point, ensuring uniform heating and molding. Other critical parameters include moisture content, which must be kept very low to prevent hydrolytic degradation during processing, and crystallinity, which affects the clarity and barrier properties of the final product. Understanding these technical details is key to selecting the right Polyplex PET Chips for Blow Molding Use supplier.

Applications of the Product

The applications of Polyplex PET chips are diverse and far-reaching. They are most commonly used in the production of beverage bottles for water, carbonated soft drinks, and juices. Their excellent gas barrier properties also make them suitable for containers of edible oils, sauces, and other food products. In the non-food sector, PET bottles are used for packaging household cleaners, cosmetics, and pharmaceuticals. The versatility and safety of PET make it a preferred material for a wide variety of packaging solutions. The quality of the raw material, supplied by MT Royal, ensures that these applications are executed with precision and reliability.

Purchasing from MT Royal

When you choose to purchase from MT Royal, you are not just buying a product; you are entering into a partnership with a leader in the Plastic Raw Materials market. We offer a seamless procurement process, from initial inquiry to final delivery. Our team of experts is available to provide technical support and guidance to ensure you select the correct grade of PET chips for your specific application. We maintain a large inventory and a robust logistics network, ensuring timely and consistent supply, which is critical for continuous manufacturing operations. Our commitment to quality and customer service is what sets us apart as a top Polyplex PET Chips for Blow Molding Use supplier.

A Strategic Choice for Your Business

Selecting the right raw material supplier is a strategic decision that can impact your entire production line. A reliable supplier ensures consistent quality, a steady supply, and competitive pricing. MT Royal is dedicated to providing all three. Our Polyplex PET chips are sourced from reputable manufacturers and are subjected to rigorous quality control processes. We understand the market dynamics and the need for efficiency and cost-effectiveness. Our mission is to empower our clients with the best raw materials, enabling them to produce high-quality products and gain a competitive edge. This is our commitment as your trusted Polyplex PET Chips for Blow Molding Use supplier.

Conclusion

In the competitive landscape of the plastics manufacturing industry, the quality of your raw materials is paramount. Polyplex PET chips are a fundamental component for the production of blow-molded products, and choosing the right supplier is a key determinant of success. MT Royal stands as a beacon of quality and reliability in this sector, offering premium Polyplex PET Chips for Blow Molding Use alongside unparalleled customer service. Our dedication to providing the finest Plastic Raw Materials makes us the ideal partner for manufacturers seeking to optimize their production processes and deliver superior products to the market. Partner with MT Royal and experience the difference that quality and reliability can make.

Reviews

There are no reviews yet.