If you manage or supply a quarry operation in Ukraine, you already understand one hard truth: stone does not forgive weak machinery. Every hour of downtime, every premature liner failure, and every unstable throughput curve translates directly into lost revenue. This is why the growing interest in TÜRKİYE-made cone crusher for Ukrainian quarries is not a trend driven by price alone, but by experience. Ukrainian quarry operators are increasingly looking for equipment that works as hard as their production schedules demand—without the excessive costs and inflexibility often associated with traditional sourcing routes.

From the very beginning, MT Royal approaches this demand with a clear philosophy. We do not treat Turkish-made cone crushers as interchangeable products. We treat them as engineered systems that must match Ukrainian quarry realities: hard rock, long operating hours, variable feed, and high expectations for reliability. We have seen first-hand how the right Turkish cone crusher, selected with technical discipline, can quietly transform a quarry’s performance profile. This article is written to give you a complete, grounded understanding of why Türkiye-made cone crushers are increasingly chosen for Ukrainian quarries—and how to evaluate them properly.

Understanding quarry operations in Ukraine

Ukraine’s quarry industry supports construction, infrastructure, cement production, and export-oriented aggregate supply. Granite, basalt, limestone, and other hard rock materials dominate many regions, placing consistent stress on crushing equipment.

Typical challenges faced by Ukrainian quarries include:

- High abrasiveness of raw material

- Seasonal temperature extremes

- Dust-intensive environments

- Pressure to maximize output with limited stoppages

In this context, cone crushers are not optional upgrades; they are core production assets. A cone crusher that performs inconsistently does not fail quietly—it destabilizes the entire processing line.

This is where the relevance of a TÜRKİYE-made cone crusher for Ukrainian quarries becomes clear.

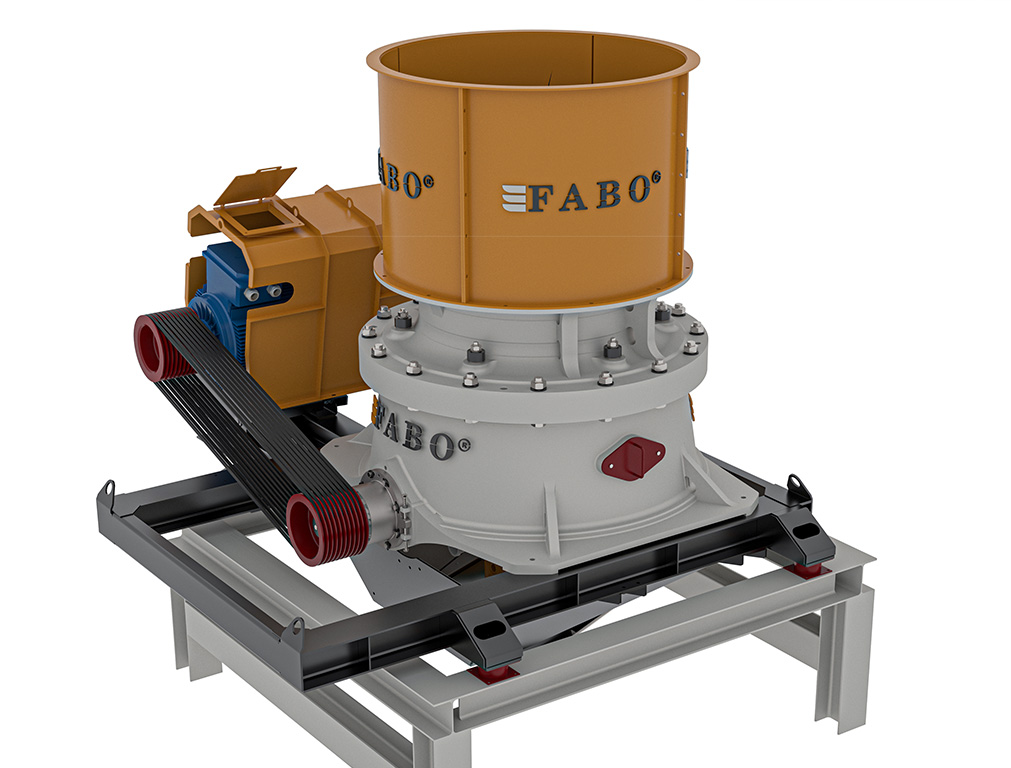

What defines a cone crusher in quarry applications

A cone crusher is often described as a secondary or tertiary crusher, but in quarry operations its role is far more strategic. It determines final particle size, shape consistency, and the efficiency of downstream screening.

Key performance factors include:

- Crushing force distribution

- Mantle and concave geometry

- Wear progression predictability

- Mechanical balance and vibration control

Cone crushers that are poorly matched to quarry conditions may run initially, but they reveal weaknesses over time through excessive wear, unstable output, and rising maintenance demands.

Turkish manufacturers have built their reputation by addressing these exact issues rather than masking them with superficial features.

Why Türkiye has become a strong manufacturing source for cone crushers

Türkiye’s heavy machinery sector did not evolve in isolation. It developed through decades of supplying mining, quarrying, cement, and construction industries across Europe, the Middle East, and Central Asia.

Several structural advantages explain the appeal of Turkish-made cone crushers:

Engineering rooted in industrial reality

Turkish manufacturers design machinery for continuous operation in demanding environments, not laboratory conditions.

Flexible manufacturing culture

Customization is common, not exceptional. Adjustments to liner profiles, feed openings, and drive systems are standard practice.

Controlled production costs

Lower operational costs allow competitive pricing without compromising metallurgy or machining accuracy.

Export experience

Many Turkish manufacturers already serve markets with geological and operational similarities to Ukraine.

For quarry operators, this means fewer compromises between performance and affordability.

What “TÜRKİYE-made cone crusher for Ukrainian quarries” really means

This phrase represents more than origin. It reflects a combination of design philosophy, material selection, and operational compatibility.

A well-specified Turkish cone crusher for Ukrainian quarries typically offers:

- Robust frame and main shaft construction

- High-quality wear parts designed for abrasive rock

- Effective dust sealing and lubrication systems

- Compatibility with existing crushing circuits

At MT Royal, we have seen that success comes not from choosing a country, but from choosing the right manufacturer within that country.

Common mistakes when sourcing cone crushers for quarries

Even experienced quarry operators can make costly mistakes during procurement.

Focusing only on purchase price

A lower upfront cost often leads to higher wear part consumption and increased downtime.

Ignoring liner design

Mantle and concave geometry directly affect throughput and wear life.

Overlooking environmental factors

Temperature fluctuations and dust levels must influence sealing and lubrication choices.

We have observed that most operational frustrations trace back to decisions made during sourcing—not operation.

Comparing Turkish cone crushers with other sourcing options

Versus Western European equipment

Western European crushers offer refined engineering but often come with high acquisition and service costs. Turkish crushers frequently deliver similar mechanical robustness with greater flexibility.

Versus Asian-manufactured crushers

Some Asian options compete aggressively on price but may struggle with long-term wear consistency and metallurgical quality.

Versus local refurbishment solutions

Refurbished machines can offer short-term savings but often lack the reliability required for continuous quarry operation.

This comparison explains why TÜRKİYE-made cone crusher for Ukrainian quarries is increasingly viewed as a balanced, long-term choice.

Technical factors Ukrainian quarry operators should prioritize

When evaluating cone crushers, several technical details deserve special attention.

Wear part metallurgy

Alloys must balance hardness with impact resistance to avoid cracking under load.

Bearing and shaft stability

Poor alignment increases vibration and accelerates component fatigue.

Lubrication system design

Stable oil flow and filtration extend bearing life significantly.

Maintenance accessibility

Ease of liner replacement and inspection reduces downtime.

We have seen quarries improve annual output simply by selecting machines that prioritize these fundamentals.

Industrial considerations for high-output quarry operations

Large-scale quarries introduce additional complexity.

Throughput consistency

Stable crushing minimizes load variation across screens and conveyors.

Energy efficiency

Optimized crushing action reduces unnecessary power consumption.

Predictable maintenance cycles

Scheduled maintenance is far cheaper than emergency repairs.

In our experience, quarries that think in terms of total cost per ton outperform those focused on initial equipment cost.

The role of MT Royal in sourcing Turkish cone crushers

Sourcing internationally requires more than selecting a machine model. It requires coordination, verification, and realistic planning.

MT Royal works as a sourcing and technical alignment partner, connecting Ukrainian quarry operators with proven Turkish manufacturers. We focus on:

- Matching crusher specifications to quarry conditions

- Evaluating manufacturer capabilities

- Supporting logistics and documentation planning

We have seen that when sourcing is handled systematically, Turkish-made cone crushers integrate smoothly into Ukrainian quarry operations.

Frequently asked questions from Ukrainian quarry managers

Can Turkish cone crushers handle Ukrainian granite and basalt?

Yes. Many are designed specifically for high-abrasion materials.

Are spare parts readily available?

With proper planning, spare parts supply can be predictable and cost-effective.

Is customization possible for existing plants?

Most Turkish manufacturers offer customization to match existing circuits.

How does service support work?

Support quality depends on preparation. Clear specifications and documentation make long-term operation manageable.

Market trends influencing quarry equipment decisions in Ukraine

Several trends are shaping procurement behavior:

- Increased focus on operational efficiency

- Preference for flexible, adaptable equipment

- Emphasis on lifetime cost rather than brand prestige

Turkish manufacturers align well with these priorities.

Why quarry operators increasingly choose Turkish solutions

Stone crushing is a long game. Equipment decisions reveal their wisdom over years, not months.

Choosing a TÜRKİYE-made cone crusher for Ukrainian quarries is not about novelty or experimentation. It is about selecting machinery that respects the reality of quarry work—machines built to endure, adapt, and perform without drama.

At MT Royal, we believe that the best equipment decisions are quiet ones. When the crusher runs steadily, wear behaves predictably, and maintenance follows a plan, operators can focus on production rather than problem-solving.

In quarrying, reliability is not a feature—it is the foundation. And the right cone crusher, chosen with clarity and experience, becomes an asset you rarely have to think about. That is when you know the decision was the right one.

No comment