If you are an American contractor working across multiple job sites, you already understand a hard truth of today’s construction and infrastructure market: fixed crushing plants are no longer enough. Projects move faster, margins are tighter, and material sources change from site to site. In this environment, portable cone crushers for American contractors are no longer a convenience—they are a strategic asset.

This is exactly why many contractors now choose to source their portable crushing solutions through MT Royal. The value is not just in the machine itself, but in how intelligently it fits into real-world operations. A well-selected portable cone crusher reduces hauling costs, shortens project timelines, improves aggregate quality, and gives contractors direct control over material production instead of relying on external suppliers.

This article is written for contractors who want clarity, not marketing noise. You will find practical explanations, operational insights, and procurement guidance grounded in how U.S. construction and infrastructure projects actually run.

What Are Portable Cone Crushers?

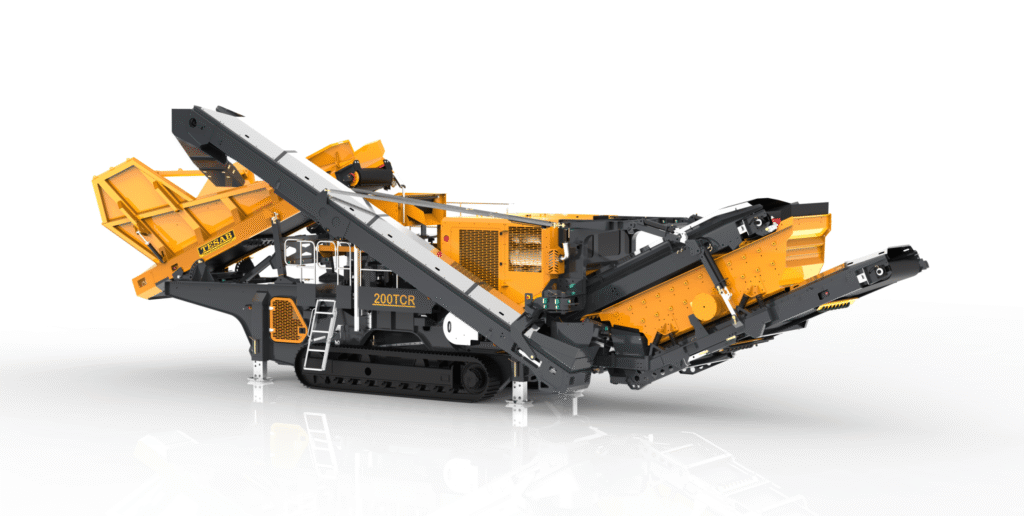

Portable cone crushers are mobile crushing units mounted on wheeled or tracked chassis, designed to perform secondary or tertiary crushing directly at or near the job site. Unlike stationary cone crushers, these systems can be relocated quickly, allowing contractors to follow the material rather than transport the material to a distant plant.

For American contractors, portability translates into flexibility:

- Crushing at remote or temporary job sites

- Rapid relocation between projects

- Reduced trucking and fuel costs

- Faster response to schedule changes

Portable cone crushers are commonly used in road construction, infrastructure projects, quarry extensions, and recycling applications where mobility and consistent product quality are equally important.

Why Portable Cone Crushers Matter in the U.S. Contracting Market

The U.S. construction market is uniquely demanding. Projects are geographically dispersed, regulatory oversight is strict, and labor costs are high. Every inefficiency compounds quickly.

Portable cone crushers for American contractors address several structural challenges:

- Rising fuel and transportation costs

- Increasing demand for on-site material processing

- Tight project deadlines with penalty clauses

- Growing focus on sustainability and material reuse

By producing high-quality aggregates directly on-site, contractors gain both economic and operational advantages.

Core Advantages of Portable Cone Crushers

On-Site Production Control

When you control your own crushing, you control your schedule. Portable cone crushers allow you to produce the exact gradation required without waiting for third-party deliveries.

Reduced Hauling and Logistics Costs

Hauling raw or crushed material over long distances is expensive. Crushing at the source minimizes fuel usage, truck wear, and logistical coordination.

Consistent Aggregate Quality

Cone crushers are known for producing well-shaped, consistent aggregates. Portable units deliver this quality without sacrificing mobility.

Faster Project Turnaround

Setup times for modern portable cone crushers are significantly shorter than traditional plants. This allows contractors to mobilize quickly and keep projects moving.

How Portable Cone Crushers Work

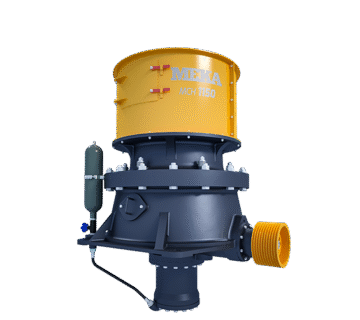

A portable cone crusher operates using a rotating mantle inside a concave bowl. Material is compressed between these surfaces until it fractures and exits at the desired size.

What differentiates portable models is not the crushing principle, but the integration:

- Mobile chassis design

- On-board power systems

- Integrated feeders and conveyors

- Automated control and safety systems

Modern portable cone crushers are engineered to operate with minimal setup and operator intervention, making them suitable for dynamic job site conditions.

Typical Applications for American Contractors

Road and Highway Construction

Portable cone crushers are widely used to produce base course, sub-base, and asphalt aggregates directly along project corridors.

Infrastructure and Public Works

Bridges, airports, rail projects, and large public works benefit from on-site crushing to reduce supply chain dependency.

Recycling and Demolition

Concrete and asphalt recycling is a growing market. Portable cone crushers allow contractors to process demolition material and reuse it on-site.

Quarry Extensions and Temporary Sites

When existing quarries cannot economically supply a project, portable crushers offer a practical alternative.

Key Engineering Features Contractors Should Evaluate

Mobility Configuration

Tracked units offer superior mobility on uneven terrain, while wheeled units are easier to transport over long distances. The right choice depends on your typical project environment.

Crushing Chamber Design

Different chamber profiles affect throughput, product shape, and wear life. Selecting the correct configuration is critical for consistent results.

Hydraulic Adjustment Systems

Hydraulic CSS (closed side setting) adjustment allows operators to change output size quickly without stopping production.

Wear Part Quality

High-grade manganese liners and predictable wear patterns reduce downtime and maintenance costs.

Automation and Monitoring

Modern portable cone crushers increasingly include automation features such as load monitoring, tramp release protection, and performance diagnostics.

Common Procurement Mistakes Contractors Make

One frequent mistake is buying based solely on headline capacity numbers. Real-world performance depends on material type, feed consistency, and operating conditions.

Another mistake is underestimating total cost of ownership. A lower upfront price can be offset quickly by higher wear costs, downtime, or poor fuel efficiency.

Contractors also sometimes overlook service and parts availability. A portable crusher that sits idle waiting for parts is not portable in any meaningful sense.

Portable Cone Crushers vs Other Mobile Crushing Options

Cone Crushers vs Impact Crushers

Impact crushers excel in high-reduction applications but typically suffer higher wear when processing hard or abrasive materials. Portable cone crushers offer longer wear life and better product shape for many construction aggregates.

Cone Crushers vs Jaw Crushers

Jaw crushers are ideal for primary crushing but produce coarser material. Portable cone crushers are better suited for producing final product or controlled gradations.

Portable vs Stationary Crushers

Stationary plants may offer higher peak capacity, but portability delivers operational flexibility that stationary systems cannot match for contractors.

Industrial-Scale Benefits for Large Contractors

For contractors managing multiple large projects, portable cone crushers offer scalability:

- One machine can serve multiple projects annually

- Capital investment is leveraged across sites

- Equipment utilization rates increase

We have seen contractors significantly reduce dependence on external aggregate suppliers by strategically deploying portable cone crushers across their project portfolio.

The Role of MT Royal in Portable Crusher Sourcing

MT Royal works with multiple manufacturers to supply portable cone crushers tailored to contractor needs. This multi-source approach allows flexibility in:

- Budget alignment

- Lead times

- Technical specifications

We have worked with contractors who needed fast deployment for emergency infrastructure repairs, as well as those planning long-term fleet upgrades. In both cases, the ability to match the right machine to the right application proved decisive.

We believe equipment sourcing should feel like problem-solving, not guessing.

Frequently Asked Questions from American Contractors

Are portable cone crushers suitable for long-term use?

Yes. When properly maintained, they are designed for continuous operation across multiple projects.

Can portable cone crushers handle recycled material?

Absolutely. Many models are specifically engineered to process concrete and asphalt recycling material.

How complex is maintenance?

Routine maintenance is straightforward, especially on modern designs with easy access to wear parts and service points.

Are these machines compliant with U.S. regulations?

Reputable portable cone crushers meet or exceed applicable safety and emissions requirements when configured correctly.

Industry Trends Shaping Portable Crushing

Several trends are accelerating adoption:

- Rising fuel and transportation costs

- Increased recycling mandates

- Labor shortages driving automation

- Demand for faster project delivery

Portable cone crushers align well with these trends, offering contractors flexibility without sacrificing quality.

Choosing the Right Portable Cone Crusher for Your Business

The “best” crusher is not universal. It depends on:

- Typical material type

- Desired output size

- Project mobility requirements

- Maintenance capabilities

MT Royal helps contractors navigate these variables, ensuring that the selected equipment aligns with operational realities rather than theoretical performance.

The Quiet Power of the Right Equipment Choice

Portable cone crushers for American contractors do not draw attention when they work well. They simply keep projects moving, crews productive, and schedules intact.

That quiet reliability is not accidental. It is the result of thoughtful engineering, informed sourcing, and realistic expectations.

When portable crushing becomes part of your operational strategy rather than an afterthought, it changes how projects are planned and executed. That shift—more than any specification sheet—is what defines long-term success in modern contracting.

No comment