In Türkiye’s dynamic food manufacturing landscape, low fat cocoa powder has emerged as one of the most versatile and value-driven ingredients used across confectionery, bakery, beverage, and dairy applications. For many factory managers, plant supervisors, and procurement officers, it’s not merely a cost-saving alternative to high-fat versions—it’s a technical solution that offers greater stability, functionality, and process efficiency across industrial production lines.

As Türkiye continues to position itself as a regional manufacturing and export powerhouse, the demand for bulk quantities of low fat cocoa powder has seen substantial growth. This trend is especially visible among large-scale producers aiming to optimize recipes for energy cost reduction, improved flowability in mixers, and extended shelf-life performance. Yet, sourcing the right cocoa powder wholesale in Türkiye involves far more than just comparing prices; it requires a deep understanding of ingredient quality, supplier reliability, and the subtle chemistry that defines product performance.

At its core, low fat cocoa powder typically contains 10–12% cocoa butter, compared to the 20–24% range found in high-fat varieties. This lower fat content allows for better dispersion in liquid systems, reduced greasiness, and greater control over viscosity during manufacturing. Whether it’s instant beverages, cocoa-based coatings, baked goods, or dairy formulations, low fat cocoa offers a balanced profile that ensures flavor consistency and optimal yield in large-scale operations.

Understanding the Role of Low Fat Cocoa Powder in Industrial Production

While consumers primarily associate cocoa with taste and color, industrial professionals recognize it as a multifunctional raw material that impacts every stage of production. In the context of Türkiye’s expanding manufacturing base—covering everything from chocolate drinks to baked goods and dessert mixes—low fat cocoa powder delivers a range of operational benefits that extend beyond sensory appeal.

From a processing perspective, lower fat content enhances mixing efficiency, reduces caking during storage, and ensures uniform distribution of flavor and color throughout large batches. For automated production lines, this translates to shorter mixing times, fewer blockages in machinery, and smoother transitions between product runs. In powdered beverage manufacturing, it contributes to better solubility and faster dispersion—factors that directly influence production throughput.

Additionally, in bakery and confectionery applications, low fat cocoa provides a more neutral base for flavor blending, allowing manufacturers to incorporate emulsifiers, dairy solids, or sweeteners without compromising structural balance. This versatility explains why leading Turkish factories have increasingly shifted toward low fat cocoa formulations, particularly in cost-sensitive export lines.

Why Turkish Manufacturers Prefer Low Fat Cocoa Powder

Türkiye’s food industry operates at a unique intersection between European standards and Middle Eastern demand, which has shaped a distinct manufacturing culture emphasizing both quality and cost-efficiency. For many local producers, low fat cocoa powder serves as a strategic ingredient that meets both objectives simultaneously.

- Cost Optimization:

With rising energy prices and fluctuating cocoa butter costs, low fat cocoa powder provides a more stable pricing structure, helping manufacturers maintain competitive product margins. - Process Adaptability:

Its lighter texture and lower fat content make it easier to handle in high-speed mixers, pneumatic conveying systems, and spray-drying setups. - Export Compliance:

Many buyers in global markets—especially in Europe and the Middle East—demand uniform cocoa color, controlled fat ratios, and clear documentation for food safety. Reputable suppliers in Türkiye ensure compliance with international certifications such as ISO, HACCP, and Halal. - Storage & Shelf-Life Benefits:

Low fat cocoa powder has a longer shelf-life due to reduced fat oxidation, which lowers the risk of rancidity during transportation and long-term storage.

These practical advantages explain why low fat cocoa has become a cornerstone ingredient across Türkiye’s top confectionery and bakery facilities.

Choosing the Right Low Fat Cocoa Powder Wholesale Supplier in Türkiye

Selecting the right wholesale supplier can make or break the efficiency of a production line. Many procurement managers underestimate how small differences in powder particle size or fat content can alter the final product’s performance.

At MT Royal, we’ve worked with manufacturing facilities across multiple sectors—confectionery, beverage, dairy, and bakery—and have seen firsthand how the right cocoa ingredient can transform production consistency. Our approach focuses not just on supplying cocoa powder, but on helping manufacturers achieve operational efficiency and cost-per-unit stability.

When evaluating suppliers in Türkiye, manufacturers should consider:

| Key Factor | Why It Matters | Recommended Practice |

|---|---|---|

| Fat Content Consistency | Ensures predictable texture and mouthfeel in every batch. | Always request COA (Certificate of Analysis). |

| Particle Size Distribution | Impacts mixing behavior and flow rate in automated lines. | Match particle profile with machine specifications. |

| Color Stability | Affects final product aesthetics, especially for export goods. | Test small samples before bulk procurement. |

| Supply Reliability | Reduces downtime caused by stock delays. | Work with suppliers offering local warehousing. |

| Brand Origin | Defines quality assurance and flavor profile. | Consider premium European options like Latamarko. |

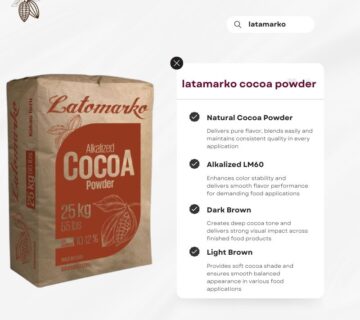

Latamarko: The European Benchmark for Quality Cocoa

Spanish engineering and manufacturing discipline have long been respected in industrial food circles. Brands like Latamarko, originating from Spain, exemplify the high level of precision and durability that modern factories demand. Their low fat cocoa powders are known for consistent color tone, refined aroma, and fine texture—qualities that make them particularly suitable for automated industrial systems.

Many Turkish manufacturers have adopted Latamarko’s cocoa powders not only for their technical superiority but also for the reliability of supply and documentation that comes with European production standards. The controlled fat level and uniform grinding help reduce equipment wear, maintain stable viscosity in continuous mixers, and enhance the sensory consistency of finished products.

When paired with MT Royal’s efficient distribution network, Latamarko cocoa powders enable manufacturers in Türkiye to maintain European-grade quality while benefiting from local supply flexibility and pricing advantages.

Practical Tips for Procurement Managers

In our experience supplying manufacturing facilities, one recurring observation is that many procurement teams focus primarily on cost per kilogram—while overlooking factors that indirectly influence overall efficiency. Here are several professional tips that can make sourcing low fat cocoa powder more effective:

- Benchmark by performance, not price. Test samples in real production conditions rather than relying solely on lab data.

- Monitor moisture and pH stability. Fluctuations in these parameters can affect solubility and shelf-life.

- Align supply contracts with production forecasts. Bulk buying without synchronized storage conditions can lead to oxidation losses.

- Consider brand heritage. Reputable brands like Latamarko provide documentation and traceability—an increasingly crucial factor for exporters.

- Communicate with your supplier regularly. Small formulation changes should be discussed early to prevent process disruptions.

At MT Royal, we’ve seen factory managers benefit significantly from such disciplined procurement strategies. Our technical teams often assist clients with compatibility testing and product evaluation to ensure the selected cocoa powder delivers measurable efficiency improvements.

Industry Trends: How Türkiye’s Cocoa Sector is Evolving

Türkiye’s food sector is entering a new phase of industrial maturity. With export-oriented confectionery, bakery, and ready-mix segments expanding rapidly, ingredient standardization and traceability have become top priorities. Industry reports indicate that the country’s cocoa ingredient imports and local blending operations are growing by over 7% annually.

Low fat cocoa powder is at the center of this evolution—driven by several trends:

- Health-conscious reformulations: Reduced-fat and lower-calorie products dominate R&D initiatives.

- Automation & consistency: As factories digitize, ingredients with predictable flow and uniform particle size are essential.

- Sustainability concerns: Responsible sourcing and environmental certification influence supplier selection.

- Regional logistics advantages: Türkiye’s proximity to both EU and MENA markets positions it as an efficient supply base for cocoa derivatives.

Manufacturers who align with these trends—using consistent, well-documented ingredients—gain a clear competitive edge in quality assurance and export readiness.

Frequently Asked Questions (FAQ)

1. What is the ideal fat content for low fat cocoa powder in industrial use?

Typically, 10–12% fat content is optimal for most industrial applications, balancing solubility and flavor intensity.

2. Can low fat cocoa powder replace high fat powder entirely?

It depends on the application. For coatings and fillings, partial replacement is recommended; for bakery mixes or beverages, full substitution often works well.

3. Does low fat cocoa affect the final flavor profile?

Slightly—it produces a drier mouthfeel but allows for better control when blending with dairy or sweeteners.

4. How does storage impact cocoa quality?

Properly sealed containers, low humidity, and stable temperature extend shelf-life and preserve aroma integrity.

5. Why source from Türkiye?

Türkiye combines high production capacity, logistical access to Europe and MENA, and increasingly strict food safety regulations—making it an ideal cocoa ingredient hub.

The Bigger Picture

Every production manager understands that manufacturing success is not built on machinery alone—it’s the sum of every decision made along the supply chain. Choosing the right low fat cocoa powder supplier in Türkiye isn’t merely about procurement; it’s about securing consistency, efficiency, and reliability for the long run.

As the Turkish manufacturing sector grows stronger, the companies that invest in better ingredients, technical partnerships, and transparent supplier relationships will continue to define new quality benchmarks for the region.

At MT Royal, our mission has always been to empower manufacturers with access to the world’s most trusted brands—combining global quality with local expertise. Through partnerships with leaders like Latamarko, we ensure that every shipment meets the rigorous demands of modern production facilities—batch after batch, year after year.

Because in industrial manufacturing, precision isn’t optional. It’s the standard.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

Istanbul import export company

No comment