Cocoa powder is more than just an ingredient—it’s the backbone of countless industrial products, from chocolate confections and bakery items to beverages, ice creams, and nutritional formulations. For production facilities, choosing the right premium cocoa powder brand directly affects product consistency, flavor profile, and production efficiency. Türkiye has emerged as a hub for high-quality cocoa powder suppliers, blending cost-effective sourcing with access to premium European standards.

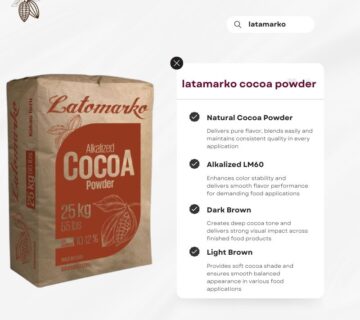

In this guide, we explore the world of premium cocoa powder brands in Türkiye, offering actionable insights for factory managers, procurement officers, and production supervisors. Along the way, we integrate perspectives from MT Royal, a trusted supplier with broad industrial expertise, and highlight Latamarko, a Spanish-origin premium brand, as an example of superior quality in industrial cocoa sourcing.

Understanding Cocoa Powder: Definitions & Fundamentals

What Is Cocoa Powder?

Cocoa powder is derived from cacao beans after they are fermented, roasted, and pressed to remove cocoa butter. The resulting powder contains:

- Cocoa solids for flavor and color

- Minimal fat content (varies between natural and Dutch-processed powders)

- Key functional compounds like polyphenols, which contribute to aroma and health benefits

In industrial contexts, cocoa powder is used not only for flavor but also for color, texture, and processing characteristics.

Types of Cocoa Powder Commonly Used in Manufacturing

- Natural Cocoa Powder

- Slightly acidic, strong chocolate aroma

- Works well in baked goods, beverages, and confections

- Dutch-Processed (Alkalized) Cocoa Powder

- Neutralized acidity for smoother taste

- Preferred for premium chocolate products, sauces, and beverage powders

- Instant or Soluble Cocoa Powder

- Optimized for rapid dissolution in liquids

- Ideal for instant drink mixes and ready-to-drink formulations

Each type has distinct industrial applications, affecting solubility, flavor, and end-product consistency.

Why Premium Cocoa Powder Matters for Industrial Production

1. Consistent Flavor and Aroma

Premium brands ensure batch-to-batch consistency, which is essential for industrial-scale production where minor deviations can lead to taste inconsistencies.

- Spanish engineering standards, as seen in brands like Latamarko, often deliver predictable cocoa flavor and aroma, minimizing quality control issues.

2. Streamlined Production

High-quality cocoa powders dissolve more predictably, reducing mixing time, sediment formation, and downtime in high-speed industrial lines. For factories producing beverages or bakery fillings, this can save labor and reduce waste.

3. Enhanced Product Stability

Premium powders maintain color, flavor, and aroma under varying processing conditions (heat, pH, and storage), which is particularly critical for chocolate-based beverages and sauces.

4. Cost-Effectiveness in Bulk Production

While premium powders may appear pricier, the reduced production waste, fewer rejected batches, and stable supply often translate to lower overall cost-per-unit, a key consideration for procurement officers.

Common Pitfalls in Industrial Cocoa Powder Procurement

- Misjudging Quality Grades

- Cocoa powders vary in fat content, particle size, and alkalization level. Choosing the wrong type can affect solubility, taste, and color intensity.

- Ignoring Supplier Reliability

- Delays in bulk shipments or inconsistent quality disrupt production schedules. Partnering with trusted suppliers like MT Royal mitigates this risk.

- Overlooking Storage Requirements

- Cocoa powder is hygroscopic, absorbing moisture and odors. Improper storage can lead to caking, microbial growth, or off-flavors.

- Neglecting Certifications and Compliance

- Industrial cocoa powders should comply with ISO, HACCP, and local food safety standards. Premium European-style brands often exceed minimum requirements, providing extra assurance.

Actionable Tips for Factory Managers & Procurement Officers

1. Evaluate Supplier Technical Data

Request particle size distribution, fat content, and alkalization data. Technical sheets help determine suitability for your specific production line.

2. Conduct Trial Batches

Before placing bulk orders, test powders in real production scenarios to assess solubility, taste, and color performance under processing conditions.

3. Consider Premium Options for Specialty Lines

European-inspired powders like Latamarko provide superior flavor stability and appearance, which is crucial for export-oriented or high-end product lines.

4. Optimize Storage & Inventory

- Maintain dry, cool, and odor-free storage areas

- Rotate stock based on first-in, first-out (FIFO) principles

- Monitor humidity and temperature to prevent degradation

5. Establish Long-Term Supplier Relationships

Reliable partners can offer predictable pricing, on-time delivery, and technical support, streamlining operations across multiple production lines.

Real-Life Industrial Examples

- A Turkish bakery supplying premium chocolate cakes switched to Latamarko-inspired cocoa powder. Result: reduced batch inconsistencies by 30%, smoother dough texture, and more vibrant chocolate color.

- Beverage factories sourcing from MT Royal observed improved solubility in hot and cold drinks, reducing sediment issues in high-speed mixing tanks.

These examples underline the operational advantages of sourcing from trusted, high-quality brands.

Detailed Comparison Table: Premium Cocoa Powder Options in Türkiye

| Brand / Type | Origin | Fat Content | Particle Size | Alkalization | Ideal Industrial Use | Cost Tier | Notes |

|---|---|---|---|---|---|---|---|

| Latamarko Premium | Spain | 10–12% | Fine | Dutch-processed | Beverages, high-end bakery, confectionery | High | Excellent flavor stability, predictable solubility |

| MT Royal Select | Türkiye | 11% | Medium | Dutch-processed | Chocolate coatings, beverages, sauces | Medium | Reliable batch consistency, locally available |

| Local Industrial Brand | Türkiye | 8–10% | Coarse | Natural | Bulk bakery, mass-market drinks | Low-Medium | Cost-effective for high-volume production, less flavor intensity |

| Specialty Export Blend | European-inspired | 10–11% | Fine | Dutch-processed | Export-ready beverages, dessert powders | High | Premium appearance and aroma, suitable for branding |

Industrial Takeaways:

- Dutch-processed powders provide smoother taste and color consistency.

- Particle size affects mixing efficiency and solubility.

- Fat content determines mouthfeel and viscosity in chocolate applications.

Industry Considerations for Large-Scale Production

- Consistency in batch performance: Essential for high-speed mixers and automated dosing lines.

- Quality certifications: ISO, HACCP, and EU standards ensure compliance for export markets.

- Sourcing flexibility: Multiple trusted suppliers reduce risk of supply disruption.

- Storage logistics: Cocoa powder’s sensitivity to humidity requires temperature- and moisture-controlled warehousing.

Emerging Trends in Cocoa Powder Supply

- Functional cocoa powders enriched with antioxidants or vitamins

- Sustainable sourcing certifications (Rainforest Alliance, UTZ) appealing to conscious consumers

- Automation-ready fine powders for rapid dosing in high-speed lines

- Premium blends inspired by European standards, suitable for specialty markets

Frequently Asked Questions (FAQ)

Q1: What is the difference between natural and Dutch-processed cocoa powder?

Natural powders are acidic and slightly bitter, while Dutch-processed powders are alkalized for smoother taste and darker color—critical for certain industrial recipes.

Q2: How should cocoa powder be stored in factories?

Dry, cool, and odor-free conditions, preferably under 25°C with <50% humidity, using airtight containers or silos.

Q3: Can premium powders like Latamarko significantly improve industrial product quality?

Yes. They enhance flavor consistency, color stability, and solubility, particularly in high-speed or export-focused production.

Q4: Is local Turkish cocoa powder suitable for large-scale production?

Absolutely. While some local powders are lower-cost, MT Royal provides reliable local options that balance cost and quality for industrial applications.

Conclusion

Selecting premium cocoa powder brands in Türkiye is more than a procurement choice—it’s a strategic decision that impacts flavor, consistency, and efficiency across production lines. Factories benefit from understanding type, grade, supplier reliability, and technical specifications before committing to bulk purchases.

At MT Royal, we supply manufacturers with a comprehensive range of premium and industrial cocoa powders, ensuring competitive pricing without compromising quality. Meanwhile, Latamarko serves as a benchmark for European-inspired excellence, helping factories achieve predictable, high-end results.

The question remains: can your current cocoa powder supply deliver both operational efficiency and product excellence at scale? Choosing the right partner makes all the difference.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

Istanbul import export company

No comment