For manufacturers operating in competitive food markets, ingredient sourcing decisions often determine production efficiency, product consistency, and profit margins. Choosing the right whole milk powder supplier in Egypt is not just a procurement task—it is a strategic decision that influences everything from texture stability to shelf life and customer satisfaction. Many factories underestimate how significantly dairy powder quality affects downstream processes until inconsistencies begin to disrupt production lines.

If your goal is to secure stable supply, predictable quality, and competitive pricing, working with an experienced partner such as MT Royal can transform procurement from a risk factor into a competitive advantage. Companies that collaborate with suppliers offering multiple international brands and technical support often gain greater flexibility when market conditions shift.

The Egyptian food manufacturing sector is expanding rapidly, driven by population growth, export opportunities, and increasing demand for processed foods. Within this environment, the role of a reliable whole milk powder supplier in Egypt becomes even more critical for factories seeking operational stability.

Understanding Whole Milk Powder and Its Industrial Importance

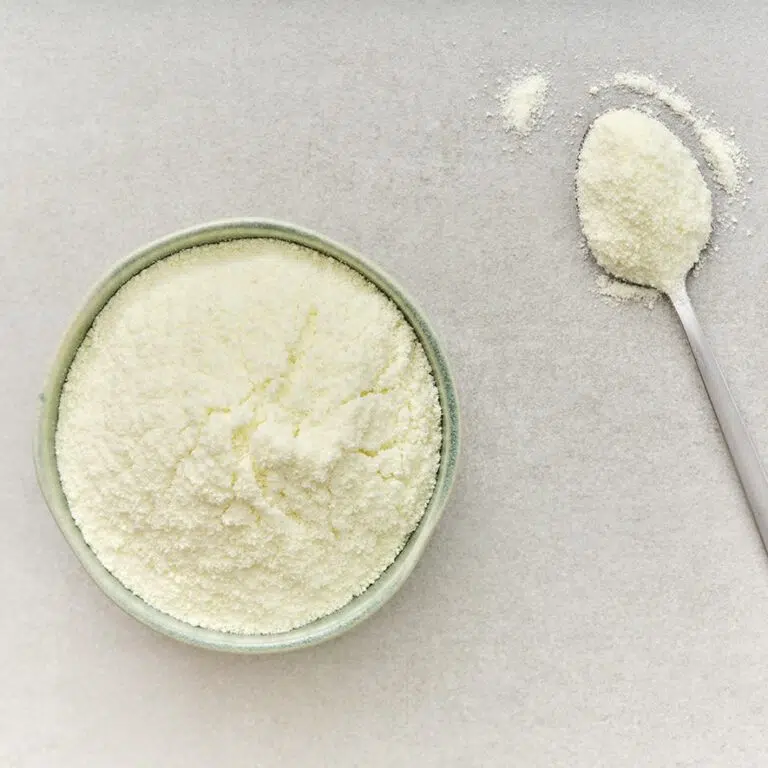

Whole milk powder (WMP), also known as full cream milk powder, is produced by spray-drying fresh milk while preserving its fat content, typically around 26–28%. Unlike skim milk powder, it retains milk fat, which contributes to:

• Rich flavor profile

• Improved mouthfeel and creaminess

• Enhanced functional performance in emulsions

• Better solubility in certain applications

For manufacturers, this means whole milk powder is not merely a dairy ingredient—it is a functional component that influences product structure, sensory attributes, and processing behavior.

Industries that rely heavily on whole milk powder include:

• Chocolate and confectionery manufacturing

• Bakery and pastry production

• Ice cream and frozen desserts

• Dairy beverages and recombined milk

• Infant and nutritional foods

• Sauces and ready meals

In large-scale production environments, consistency is everything. A slight variation in protein or fat content can affect viscosity, emulsification, or heat stability, potentially disrupting entire batches.

Key Characteristics Manufacturers Should Evaluate

When sourcing from a whole milk powder supplier in Egypt, factories should analyze several technical parameters rather than focusing solely on price.

Fat Content and Composition

Milk fat directly affects flavor intensity and texture. Premium applications such as chocolate require stable fat profiles to ensure proper crystallization and mouthfeel.

Solubility and Dispersibility

Instant whole milk powder offers improved wettability and dispersion, which is essential for beverage production lines where mixing time impacts throughput efficiency.

Microbiological Quality

Low total plate counts and absence of pathogens are non-negotiable for food safety compliance, particularly for export-oriented manufacturers.

Heat Stability

Applications involving pasteurization or high-temperature processing demand powders with strong thermal tolerance to prevent coagulation or sedimentation.

Shelf Life Stability

Oxidation resistance is critical in hot climates. Packaging technology and storage conditions significantly influence product longevity.

Common Mistakes When Choosing a Whole Milk Powder Supplier

Procurement errors can create hidden costs far exceeding initial price savings. Based on industry experience, several mistakes frequently occur.

Prioritizing Price Over Functional Performance

Lower-cost powders may require process adjustments, additional stabilizers, or higher usage rates, ultimately increasing production expenses.

Ignoring Supply Chain Reliability

Factories sometimes focus on immediate availability without evaluating long-term supply consistency. Production interruptions caused by delayed shipments can be extremely costly.

Overlooking Technical Documentation

Certificates of analysis, traceability records, and quality certifications such as ISO or FSSC 22000 are essential for regulatory compliance and export readiness.

Not Testing at Industrial Scale

Laboratory samples may perform differently in full-scale production. Pilot trials are crucial before committing to large contracts.

In our collaboration with various factories, we have seen that companies investing time in technical validation before purchasing significantly reduce operational risks.

Advantages of Working with a Multi-Brand Supplier

A whole milk powder supplier offering multiple international origins provides strategic flexibility. Different regions produce milk powder with varying characteristics due to feed, climate, and processing technology.

Benefits include:

• Alternative sourcing during global shortages

• Ability to match powder functionality with application needs

• Competitive pricing through diversified supply chains

• Reduced dependency on a single manufacturer

This approach is particularly valuable in volatile dairy markets where global milk production cycles impact availability and pricing.

Applications Across Food Industries

Whole milk powder serves different functional roles depending on the sector.

Chocolate and Confectionery

Milk powder contributes lactose and milk fat, influencing sweetness perception and texture. Consistent particle size distribution ensures smooth chocolate without grittiness.

Bakery and Pastry

It enhances browning reactions, improves crumb softness, and extends shelf life by retaining moisture.

Dairy Beverages

Instantized powders allow rapid reconstitution, reducing mixing energy requirements in beverage plants.

Ice Cream Production

Milk solids support emulsification and improve freeze-thaw stability, contributing to creamy texture.

Ready Meals and Sauces

Whole milk powder provides richness and acts as a natural flavor enhancer.

Industrial Tips for Large-Scale Production Efficiency

Factories often overlook small adjustments that can significantly improve performance when using whole milk powder.

Optimize Hydration Temperature

Reconstitution between 45–55°C typically improves solubility without damaging proteins.

Control Mixing Shear

Excessive shear can destabilize emulsions, especially in high-fat formulations.

Monitor Storage Conditions

Humidity and heat exposure can cause caking or oxidation. Climate-controlled warehouses are essential in warm regions.

Standardize Reconstitution Protocols

Consistent procedures reduce batch variability and improve quality control outcomes.

We have observed that factories implementing standardized hydration protocols often achieve more predictable product texture and reduce production waste.

Market Trends Influencing Whole Milk Powder Supply in Egypt

The dairy ingredient market is evolving due to global and regional factors.

Growing Demand for Processed Foods

Urbanization and lifestyle changes are increasing consumption of bakery, confectionery, and dairy-based beverages.

Import Dependency

Many countries in the Middle East and North Africa rely on imported dairy powders due to limited local milk production capacity.

Price Volatility

Global milk supply fluctuations, feed costs, and energy prices directly influence powder pricing.

Sustainability Concerns

Manufacturers increasingly seek suppliers with sustainable sourcing practices and transparent supply chains.

For procurement managers, understanding these trends helps anticipate risks and plan long-term contracts more effectively.

Comparing Whole Milk Powder with Skim Milk Powder

While both products originate from milk, their functional differences are significant.

Whole Milk Powder Advantages:

• Higher fat content for richer flavor

• Better mouthfeel in premium products

• Improved emulsification properties

Skim Milk Powder Advantages:

• Longer shelf life due to lower fat

• Lower cost per kilogram

• Suitable for low-fat formulations

Selecting between them depends on product formulation goals rather than simple cost comparisons.

How to Evaluate a Reliable Whole Milk Powder Supplier in Egypt

Manufacturers should consider a structured evaluation process.

Key criteria include:

• Quality certifications and compliance

• Consistent product specifications

• Logistics capability and delivery timelines

• Technical support availability

• Brand portfolio diversity

• Competitive pricing structure

Suppliers like MT Royal, which provide access to multiple global brands at competitive rates, allow factories to optimize procurement strategies without compromising quality.

Logistics and Storage Considerations in Warm Climates

Egypt’s climate introduces unique challenges for dairy powder storage.

Important practices include:

• Temperature-controlled warehouses

• Moisture-resistant packaging

• First-in-first-out inventory rotation

• Regular quality inspections

Ignoring storage conditions can degrade product functionality before it even reaches production.

Frequently Asked Questions from Procurement Teams

What is the typical shelf life of whole milk powder?

Most whole milk powders have a shelf life of 18–24 months when stored properly in cool, dry conditions.

How does instant whole milk powder differ from regular powder?

Instant powder undergoes additional processing to improve wettability and dispersibility, making it ideal for beverage applications.

Can whole milk powder replace fresh milk in production?

Yes, recombined milk from powder offers consistent composition and longer storage stability, often preferred in industrial environments.

What certifications should a supplier provide?

Common certifications include ISO standards, HACCP, FSSC 22000, Halal certification, and certificates of analysis for each batch.

How can factories reduce costs when using milk powder?

Optimizing formulations, improving hydration efficiency, and negotiating long-term contracts with reliable suppliers can significantly reduce expenses.

Specialized Insights for Procurement Strategy

Experienced purchasing managers treat dairy ingredients as strategic commodities rather than routine purchases.

Effective strategies include:

• Diversifying supply sources to reduce risk

• Monitoring global dairy price indices

• Establishing long-term partnerships with trusted suppliers

• Conducting periodic supplier audits

• Maintaining safety stock levels

When procurement is aligned with production planning, factories gain resilience against market fluctuations.

The Role of Technical Support in Supplier Relationships

A strong supplier relationship extends beyond delivery. Technical consultation can help manufacturers:

• Optimize formulations

• Improve production efficiency

• Troubleshoot quality issues

• Develop new products

We believe that suppliers who understand manufacturing realities create far more value than those who simply ship ingredients.

Future Outlook for Whole Milk Powder Demand in Egypt

Several factors indicate continued growth:

• Expanding food processing sector

• Increasing export opportunities

• Rising consumer demand for convenience foods

• Technological improvements in dairy processing

Manufacturers that secure reliable supply partnerships today position themselves better for future expansion.

Final Thoughts for Industrial Buyers

Choosing a whole milk powder supplier in Egypt is not just about purchasing an ingredient—it is about securing production stability, protecting product quality, and strengthening competitive positioning. The right supplier becomes part of your operational ecosystem, supporting your factory’s performance rather than adding uncertainty.

Factories that invest in strategic sourcing relationships, technical validation, and diversified supply options consistently outperform those that rely solely on short-term purchasing decisions. In an industry where margins are tight and consistency defines brand reputation, ingredient reliability becomes a silent but powerful competitive advantage.

LATAMARKO LM60 – Premium Spanish-Origin Cocoa Powder

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Price: Complete Buyer Guide for 2026

No comment