Advanced Technical Solutions for Bloom, Tempering, Viscosity, Texture, and Raw Material Optimization

By Dr. Meryem Bilgin | Strategic Focus on Premium Cocoa Ingredients

Introduction: Why Most Chocolate Defects Are Not Machinery Problems

In modern chocolate manufacturing, it is tempting to blame equipment when quality deviations appear. However, in real industrial practice, machinery is rarely the true root cause. After more than two decades working in cocoa processing, chocolate formulation, and industrial production systems, one conclusion remains consistent:

Most chocolate defects originate upstream — not on the production line.

Recurring issues such as:

- Fat bloom and sugar bloom

- Viscosity instability during processing

- Dull or matte surfaces

- Cracking and structural weakness

- Surface stickiness

- Inconsistent flavor and mouthfeel

are almost never random. They are the predictable outcome of structural imbalances within the chocolate system.

Across industrial facilities worldwide, these problems can be traced back to three critical variables:

– Raw Material Instability

Variations in cocoa butter crystallization behavior, cocoa powder pH, fat content, particle size distribution, and emulsifier compatibility directly influence processing performance and final product stability. Even minor batch-to-batch inconsistencies can destabilize tempering curves and rheological control.

– Improper Fat Crystallization Control

Chocolate is fundamentally a crystallized fat matrix. Without precise control over polymorphism — specifically the dominance of stable Form V cocoa butter crystals — surface gloss, snap, shelf life, and bloom resistance cannot be guaranteed.

– Environmental Mismanagement

Temperature fluctuation, uncontrolled humidity, dew point variation, and poor cooling tunnel calibration are silent contributors to sugar bloom, fat migration, structural stress, and surface defects.

Chocolate Is a Scientific System — Not Just a Recipe

Industrial chocolate is a highly engineered fat-particle suspension system. Its performance is governed by:

- Crystallization kinetics

- Polymorphic fat behavior

- Rheological balance

- Moisture control

- Ingredient compatibility

- Thermal gradients during cooling

When any one of these parameters drifts outside optimal ranges, quality deterioration becomes inevitable — regardless of how advanced or automated the production line may be.

A state-of-the-art tempering machine cannot compensate for unstable cocoa butter.

A modern cooling tunnel cannot correct poorly balanced rheology.

Automation cannot fix inconsistent cocoa powder functionality.

True production stability begins at the molecular level — with the right cocoa ingredients.

A Strategic Approach to Industrial Chocolate Stability

This comprehensive technical guide examines the most critical defects in chocolate manufacturing and provides scientifically grounded, industrial-level solutions designed for professional producers.

Beyond troubleshooting, this article emphasizes a fundamental strategic principle:

Sustainable chocolate quality is built on consistent, high-performance cocoa ingredients.

For manufacturers seeking long-term process stability, bloom resistance, controlled viscosity, predictable tempering behavior, and refined flavor development, ingredient selection is not a purchasing decision — it is a structural investment.

Companies such as MT ROYAL CO., TÜRKİYE, together with its European cocoa brand LATAMARKO (Spain), focus on delivering industrial-grade cocoa powders, cocoa butter, and cocoa liquor engineered for batch-to-batch consistency, controlled alkalization, stable fat crystallization behavior, and reliable processing performance.

In high-volume chocolate production, precision begins long before the first mixing stage — it begins with scientifically controlled raw materials.

The following sections will explore, in technical depth, how to identify, diagnose, and permanently resolve the most critical chocolate manufacturing challenges — from bloom formation to rheology optimization — through a combination of process engineering and strategic ingredient selection.

Why Does Chocolate Bloom?

Causes, Types, and Industrial Solutions

Chocolate bloom is the most visible and commercially damaging defect in chocolate production.

H3: What Is Chocolate Bloom?

Bloom appears as a whitish-gray film on the chocolate surface. It is not microbial spoilage but a structural instability within the fat or sugar system.

There are two types:

- Fat Bloom

- Sugar Bloom

Fat Bloom – The Crystallization Failure

Fat bloom results from cocoa butter polymorphic transition — typically from stable Form V to thermodynamically stable but visually undesirable Form VI.

Industrial Causes of Fat Bloom

- Incorrect tempering curve

- Temperature fluctuations during storage

- Incompatible fats (CBR/CBS mixing)

- Cocoa butter fraction inconsistency

- Poor cooling tunnel design

Industrial Solutions

- Strict temper index monitoring

- Maintaining storage at 16–18°C

- Humidity below 50%

- Ensuring cocoa butter polymorphic stability

- Using high-quality, well-processed cocoa liquor

Ingredient quality determines bloom resistance.

Fat Bloom vs Sugar Bloom in Chocolate Manufacturing

| Parameter | Fat Bloom | Sugar Bloom |

|---|---|---|

| Root Cause | Fat recrystallization | Moisture exposure |

| Texture | Smooth, greasy | Rough, grainy |

| Reversibility | Can be remelted | Permanent |

| Prevention | Correct tempering | Humidity control |

Sugar bloom occurs when moisture dissolves surface sugar and recrystallizes it after drying.

Production facilities must control dew point, not only temperature.

Common Chocolate Tempering Problems and How to Fix Them

Tempering is controlled fat crystallization — not simply heating and cooling.

Typical Tempering Defects

- Dull surface

- Soft snap

- Slow setting

- Early bloom formation

Scientific Explanation

Cocoa butter contains six polymorphic forms (I–VI).

Only Form V delivers:

- Gloss

- Sharp snap

- Proper melting profile (33–34°C)

Failure to promote Form V dominance leads to instability.

Industrial Correction

- Calibrate temper meter

- Control shear rate in tempering machine

- Maintain 31–32°C for dark chocolate

- Use cocoa butter with predictable crystallization behavior

Stable cocoa butter quality is essential for tempering success.

Chocolate Viscosity Control in Industrial Production

Viscosity determines:

- Mold filling efficiency

- Coating thickness

- Mouthfeel

- Air release

Rheological Parameters

Measured by:

- Casson Yield Value

- Plastic Viscosity

Factors Affecting Viscosity

- Cocoa butter percentage

- Lecithin dosage

- Particle size distribution

- Conching time

- Temperature

When Chocolate Is Too Thick

- Low fat content

- Poor lecithin dispersion

- Over-refining

When Chocolate Is Too Thin

- Excess cocoa butter

- High temperature

- Lecithin overdose

Consistent cocoa powder and cocoa liquor quality reduce rheological variability.

Why Chocolate Loses Its Shine After Production

Loss of gloss indicates:

- Improper tempering

- Fat bloom onset

- Condensation

- Incorrect cooling profile

Gloss depends on:

- Smooth mold surface

- Controlled crystallization rate

- Proper demolding timing

A stable fat crystal network ensures surface brilliance.

Chocolate Cracking and Breaking Defects

Cracking is often caused by:

- Rapid cooling (thermal shock)

- Uneven cooling gradient

- Incorrect fat-to-solid ratio

- Mechanical stress during demolding

Cooling Tunnel Optimization

- Multi-zone cooling

- Gradual temperature drop

- Controlled airflow velocity

- Dew point management

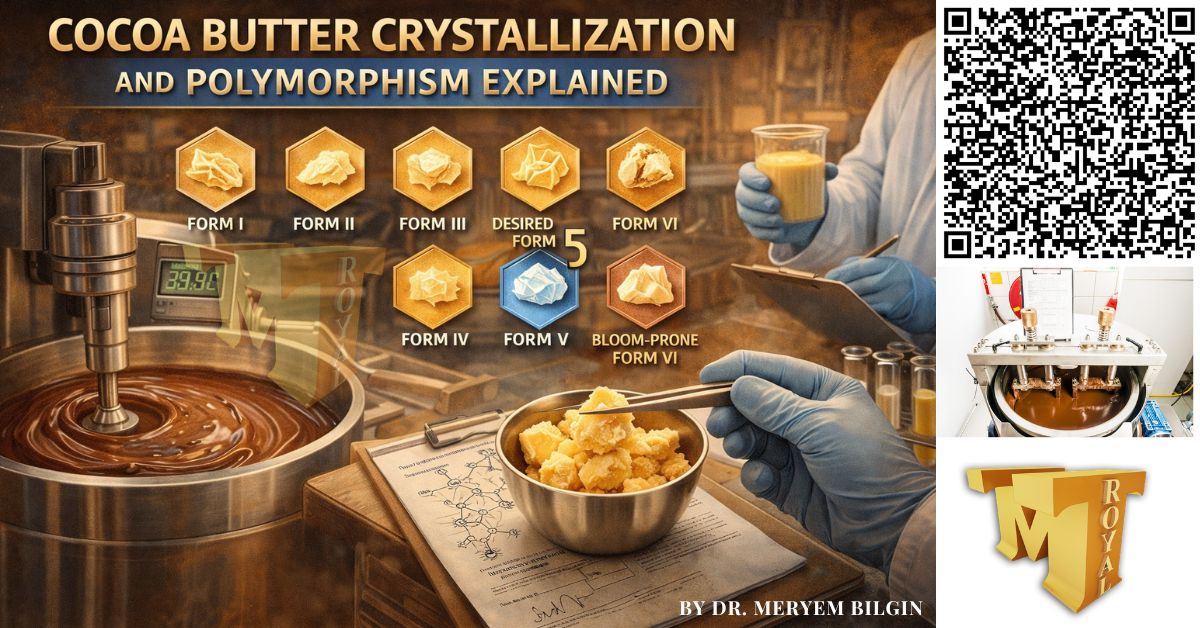

Cocoa Butter Crystallization and Polymorphism Explained

Cocoa butter polymorphism is the core science behind chocolate stability.

The Six Forms

Form I → Unstable

Form II

Form III

Form IV

Form V → Desired

Form VI → Bloom-prone

Professional chocolate manufacturing requires:

- Polymorphic control

- Stable cocoa butter source

- Accurate thermal curves

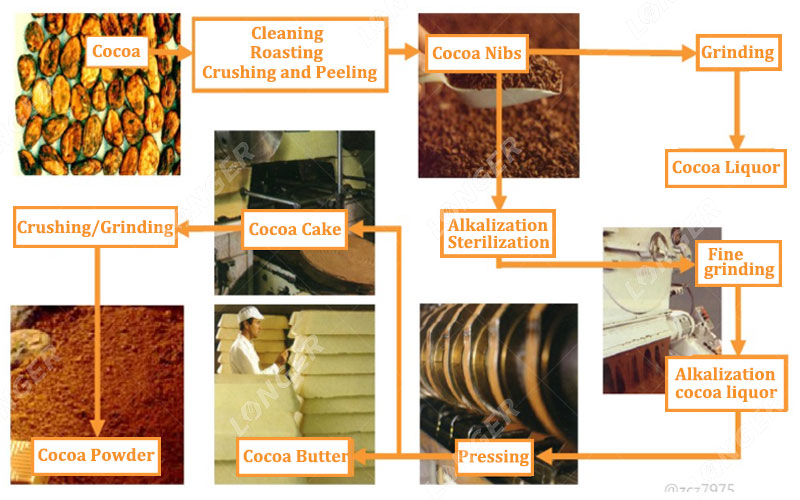

How Cocoa Powder Quality Affects Chocolate Color and Flavor

Cocoa powder significantly impacts:

- Final color intensity

- Flavor complexity

- Bitterness balance

- Aroma retention

Key Parameters

- pH level

- Fat content (10–12% standard)

- Particle size

- Roast profile

- Alkalization degree

Low-grade cocoa powder leads to:

- Dusty mouthfeel

- Weak aroma

- Poor color depth

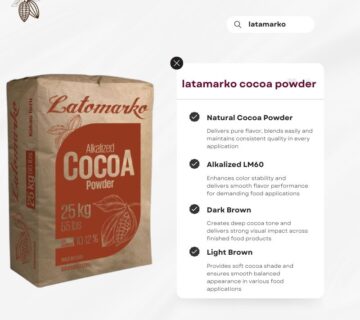

Premium European cocoa powders — such as those produced under the LATAMARKO brand — offer consistent pH control and industrial reliability.

Air Bubbles and Pinholes in Chocolate Bars

Causes:

- High viscosity

- Insufficient vibration

- Rapid crystallization

- Poor mold design

Solutions:

- Adjust vibration frequency

- Optimize fill temperature

- Control rheology

Chocolate Cooling Tunnel Problems and Optimization

Common issues:

- Uneven crystallization

- Surface condensation

- Warping

- Structural stress

Optimization requires:

- Zoned temperature control

- Air humidity monitoring

- Proper belt speed

Why Chocolate Becomes Too Thick or Too Thin During Processing

Chocolate rheology shifts during:

- Extended conching

- Temperature fluctuation

- Ingredient inconsistency

Continuous in-line rheology monitoring is recommended in large-scale production.

Chocolate Storage and Shelf Life Challenges

Shelf life is affected by:

- Temperature cycling

- Odor contamination

- Moisture exposure

- Fat migration

Ideal conditions:

- 16–18°C

- <50% relative humidity

- Odor-free warehouse

Effects of Humidity on Chocolate Quality

Humidity causes:

- Sugar bloom

- Surface stickiness

- Packaging adhesion problems

- Mold release defects

Industrial chocolate facilities must control dew point, not only ambient temperature.

How to Prevent Chocolate Stickiness

Stickiness is caused by:

- Incomplete crystallization

- High humidity

- Surface condensation

Solutions:

- Improve cooling profile

- Maintain environmental control

- Ensure correct temper index

Common Molding Defects in Chocolate Manufacturing

Typical molding issues:

- Incomplete filling

- Surface waves

- Uneven thickness

- Poor demolding

Precision in viscosity and tempering eliminates most molding defects.

Chocolate Flavor Development: From Bean to Bar

Flavor evolves through:

- Fermentation

- Drying

- Roasting

- Conching

Key compounds:

- Pyrazines

- Aldehydes

- Esters

Consistent cocoa liquor ensures stable flavor development.

Chocolate Texture Problems and Mouthfeel Control

Ideal particle size:

18–25 microns

Poor refining leads to sandy texture.

Fat distribution impacts melt profile and creaminess.

How Alkalization Impacts Cocoa Powder Performance in Chocolate

Alkalization:

- Increases pH

- Darkens color

- Reduces acidity

- Improves dispersion

However:

Over-alkalization reduces flavor complexity.

Balanced alkalization is critical for industrial chocolate applications.

Sustainable Cocoa and Its Role in Chocolate Quality

Sustainable sourcing ensures:

- Fermentation consistency

- Bean quality stability

- Ethical compliance

- Long-term supply security

Quality begins at origin.

How to Select the Right Cocoa Ingredients for Premium Chocolate

Premium chocolate manufacturing requires:

✔ Stable cocoa butter crystallization

✔ Controlled cocoa powder pH

✔ Consistent fat content

✔ European-standard processing

✔ Reliable batch-to-batch consistency

Why MT ROYAL & LATAMARKO Are Strategic Partners for Industrial Chocolate Producers

Professional chocolate production demands ingredient consistency.

MT ROYAL CO., TÜRKİYE, with over 18 years of experience in cocoa trading and manufacturing, supplies industrial-grade cocoa ingredients globally.

Under its European brand LATAMARKO (Spain), the company provides:

- Natural Cocoa Powder (10–12%)

- Alkalized Cocoa Powder (various pH and color ranges)

- Dark & Black Cocoa Powder

- Cocoa Butter

- Cocoa Liquor

Competitive Advantages:

- European production standards

- Stable batch-to-batch quality

- Professional logistics & export documentation

- Flexible payment structures

- Industrial-scale reliability

For chocolate manufacturers aiming to eliminate bloom, control viscosity, optimize tempering, and improve flavor stability — ingredient consistency is the foundation.

Final Strategic Conclusion

Most chocolate defects are not equipment failures.

They are the result of:

- Unstable cocoa butter crystallization

- Inconsistent cocoa powder performance

- Poor environmental control

- Ingredient variability

High-performance chocolate manufacturing begins with scientifically controlled cocoa ingredients.

If your production line demands:

- Bloom-resistant structure

- Stable rheology

- Predictable tempering behavior

- Consistent flavor development

Then ingredient selection becomes a strategic decision — not a purchasing decision.

LATAMARKO LM60 – Premium Spanish-Origin Cocoa Powder

Food industry raw materials – list of products

No comment