In today’s highly competitive food industry, the type of cocoa powder you choose has a direct and powerful impact on your final product cost. Among all cocoa varieties, alkalized cocoa powder plays a critical role in both production performance and overall profitability.

Alkalized cocoa powder, also known as Dutch-processed cocoa, is treated with carefully controlled alkaline solutions to modify its natural acidity. This process transforms the cocoa’s color, flavor, solubility, and stability. The result is a smoother taste, deeper color spectrum, better dispersion in liquid systems, and greater consistency during industrial processing.

From a cost perspective, alkalized cocoa powder is not simply a raw ingredient — it is a technical component that influences every stage of production. Higher alkalization quality leads to:

-

lower formulation waste

-

reduced production downtime

-

improved product uniformity

-

longer shelf life of finished goods

All of these factors directly reduce operational costs and increase profit margins.

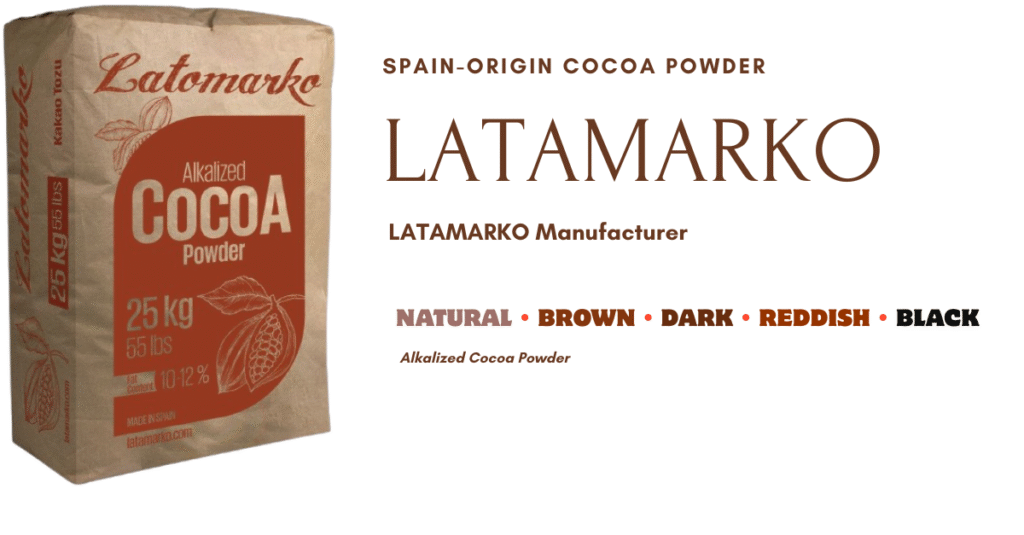

The degree of alkalization determines whether cocoa powder appears light brown, reddish brown, dark brown, or deep black. Each level requires specific processing conditions, energy consumption, chemical control, and quality management. These technical requirements explain why not all alkalized cocoa powders are priced equally in the market.

For manufacturers of chocolate, bakery products, beverages, dairy applications, and confectionery, choosing the right alkalized cocoa powder is not a matter of taste alone — it is a strategic financial decision. The wrong cocoa grade can increase recipe costs, compromise product stability, and create unpredictable production losses.

This is why professional buyers increasingly focus not only on the alkalized cocoa powder price, but also on the production standards, technical expertise, and long-term reliability of their cocoa supplier.

In the next section, we will break down the key factors that influence alkalized cocoa powder price and explain how each one affects your manufacturing cost structure.

Key Factors That Influence Alkalized Cocoa Powder Price

Understanding the alkalized cocoa powder price requires much more than checking a supplier’s quotation. For professional buyers, importers, and food manufacturers, pricing is the final result of multiple technical and commercial variables that directly affect production performance, consistency, and long-term profitability. The following factors explain why alkalized cocoa powder prices vary significantly across the global market.

1. Cocoa Bean Origin

Cocoa bean origin is the foundation of quality and price. Different growing regions produce beans with distinct flavor profiles, fat composition, fermentation characteristics, and processing behavior. West African beans often deliver strong cocoa notes and stable fat content, while Latin American and selected Asian origins offer refined aroma profiles and smoother processing behavior.

Higher-quality bean origins require strict agricultural control, better fermentation management, and careful post-harvest handling. These processes increase raw material cost but result in superior cocoa liquor and ultimately higher-grade alkalized cocoa powder. For manufacturers, this translates into more stable production, fewer formulation adjustments, and lower waste — directly impacting total production cost.

Low-grade origins may appear cheaper at purchase, but they frequently introduce inconsistent color, weak aroma, and unstable processing behavior that increases rejection rates and production losses.

2. Fat Content

Fat content is one of the most powerful drivers of alkalized cocoa powder price. Cocoa powder typically ranges from 8% to over 22% cocoa butter content, and each fat level requires different pressing techniques, yield control, and processing investment.

Higher fat content enhances mouthfeel, aroma release, dispersion, and finished product richness. It also improves lubrication inside processing equipment, reducing friction, energy consumption, and mechanical wear. These benefits justify higher production cost and higher market pricing.

Lower fat cocoa powders are less expensive, but they often demand additional formulation adjustments such as emulsifiers, flavor enhancers, or stabilizers — hidden costs that reduce the apparent price advantage.

3. Alkalization Level

The alkalization process itself is one of the most expensive and technically demanding stages of cocoa processing. Precise control of alkalizing agents, reaction time, temperature, and moisture conditions determines final product quality.

Light alkalization preserves mild cocoa flavor and natural brown color. Heavy alkalization produces deep dark or black cocoa with distinctive color strength and unique flavor profile. Each step upward in alkalization intensity increases processing complexity, energy consumption, equipment load, and quality control requirements — all reflected in final price.

Inconsistent alkalization leads to unstable color, off-flavors, and poor solubility, forcing manufacturers to correct formulas repeatedly and increasing production cost.

4. Color Classification (Light, Reddish, Dark, Black)

Color is not merely visual — it represents the full history of processing decisions. Light brown cocoa demands gentle alkalization and precise fermentation control. Reddish cocoa requires controlled heat profiles and alkalization balance. Dark and black cocoa involve extended alkalization, specialized reactors, higher energy consumption, and advanced filtration systems.

Black cocoa, in particular, commands premium pricing due to its complex processing, low moisture tolerance, strict pH control, and extremely narrow quality margin. The deeper the color, the higher the investment required at every stage of production.

For manufacturers, stable color eliminates costly recipe reformulations and guarantees consistent shelf appearance — a key driver of brand value and consumer trust.

5. Moisture and pH Control

Moisture and pH are two invisible parameters that dramatically influence price and performance. Premium alkalized cocoa powder requires strict moisture control typically below 4.5% to ensure long shelf life, free-flowing behavior, and microbiological safety.

Precise pH control ensures color stability, flavor balance, and predictable reaction behavior in chocolate, beverage, and bakery systems. Achieving tight moisture and pH tolerances requires sophisticated drying technology, inline monitoring systems, and continuous laboratory verification — all of which increase production cost but reduce risk for the buyer.

Products outside optimal moisture or pH ranges may be cheaper, but they generate serious long-term risks including clumping, microbial instability, flavor drift, and production failures.

6. Certification and Quality Standards

International certifications such as ISO, HACCP, FSSC, Halal, Kosher, and full traceability documentation represent a major investment for producers. Compliance requires certified facilities, trained personnel, documented procedures, continuous audits, and full process transparency.

While certified alkalized cocoa powder commands higher market prices, it dramatically reduces legal, regulatory, and reputational risk for manufacturers. In regulated markets, certified supply is not optional — it is mandatory for sustainable operations.

Conclusion: Price Is the Sum of Performance

The real cost of alkalized cocoa powder is measured not only at purchase, but across the entire production cycle: processing efficiency, waste reduction, quality stability, brand reputation, and customer satisfaction. The smartest buyers evaluate alkalized cocoa powder price as a long-term investment — not a short-term expense

Average Alkalized Cocoa Powder Price in Global Market

When buyers search for alkalized cocoa powder price, what they truly want to understand is not a fixed number, but the price structure of the global market and the forces that move it. Unlike commodity ingredients with rigid pricing, alkalized cocoa powder pricing is highly dynamic and influenced by multiple international variables.

There is no universal price for alkalized cocoa powder. Instead, the market operates within constantly shifting price ranges based on quality level, processing specifications, global cocoa supply, logistics costs, currency fluctuations, and seasonal production cycles.

Global Market Price Structure

On the international B2B market, alkalized cocoa powder is generally categorized into several commercial tiers:

Standard Industrial Grade

Produced for mass-market bakery and beverage use, offering stable performance and moderate color strength.

Premium Grade

Higher alkalization precision, controlled fat content, consistent color, superior solubility, and extended shelf stability.

Specialty Grades (Dark, Reddish, Black)

Technically complex processing, higher energy consumption, tight moisture and pH tolerances, and premium visual performance.

Each tier commands a different market range and attracts different buyer profiles.

Why Prices Fluctuate Constantly

Several global forces shape average alkalized cocoa powder price trends:

-

Cocoa bean harvest volumes and weather patterns

-

Geopolitical developments in major cocoa-producing regions

-

International shipping capacity and freight volatility

-

Energy prices affecting processing and drying costs

-

Currency movements impacting export competitiveness

-

Rising demand from emerging food manufacturing markets

These variables ensure that average prices rarely remain stable for extended periods. Professional buyers therefore focus on long-term supply contracts and price stability mechanisms rather than short-term spot pricing.

Factory-Level vs Trading-Level Pricing

One of the largest price differences in the market comes from whether the buyer sources directly from a manufacturer or through multiple layers of traders. Factory-direct procurement eliminates intermediary margins, improves technical support, and allows better control of specifications, all of which lower the buyer’s true cost over time.

The Hidden Cost of Cheap Cocoa Powder

Lower initial quotations often conceal higher operational costs:

-

frequent formulation corrections

-

inconsistent product color

-

higher rejection rates

-

unstable shelf life

-

greater production downtime

When total cost of ownership is considered, premium and stable supply often proves more economical than low-priced alternatives.

Smart Pricing Strategy for Buyers

Experienced buyers do not chase the lowest unit price. Instead, they evaluate suppliers on:

-

consistency of quality

-

reliability of long-term supply

-

technical support capability

-

logistics strength

-

documentation and compliance

These factors collectively define the true market value of alkalized cocoa powder.

How to Buy Alkalized Cocoa Powder at Factory Price

When buyers search for alkalized cocoa powder price, their ultimate goal is not simply to find a number, but to secure the most reliable supply at the most competitive factory level cost. Purchasing alkalized cocoa powder at factory price requires a strategic approach that combines technical knowledge, supplier selection, and long-term planning.

The first and most important step is understanding the difference between manufacturers and traders. True manufacturers control raw material sourcing, processing, alkalization, and quality testing within their own facilities. This vertical integration allows them to offer consistent product specifications and stable pricing structures that are impossible for traders who depend on external production.

Direct factory procurement eliminates multiple layers of markup, reduces communication errors, and provides buyers with direct access to technical support and customization options. When negotiating alkalized cocoa powder price at factory level, buyers should always prioritize suppliers who can demonstrate full production control, transparent documentation, and long-term supply capability.

Another key factor is specification clarity. Buyers who define their technical requirements precisely—such as fat content, alkalization level, color class, moisture range, and pH profile—avoid costly reformulations and inconsistent batches. Clear specifications protect both the buyer and the producer from misunderstandings that often lead to unexpected cost increases.

Long-term purchasing agreements also play a crucial role in securing stable alkalized cocoa powder price structures. Suppliers are far more willing to offer factory-level pricing advantages when buyers commit to regular volume schedules. Predictable demand allows manufacturers to optimize production planning, raw material procurement, and energy usage, creating cost efficiencies that can be shared with the buyer.

Logistics planning is equally important. Buyers who coordinate shipment schedules, packaging formats, and destination requirements in advance prevent last-minute changes that typically increase transport costs and disrupt delivery timelines. A well-structured logistics plan transforms the apparent alkalized cocoa powder price into a controlled and predictable investment.

Finally, buyers should always evaluate the total cost of ownership, not just the unit price. Technical reliability, quality consistency, regulatory compliance, and responsive customer support are long-term financial advantages that often outweigh small differences in initial quotation.

In the global cocoa market, the most successful buyers are not those who negotiate the lowest visible price, but those who build sustainable factory-level partnerships that deliver stable quality, controlled cost, and long-term profitability.

Why LATAMARKO Is a Smart Choice for Long-Term Supply

In the global cocoa industry, long-term success is built on supply stability, technical consistency, and financial predictability. For professional buyers evaluating alkalized cocoa powder price, choosing the right partner is often more important than choosing the lowest quotation. This is where LATAMARKO clearly stands apart.

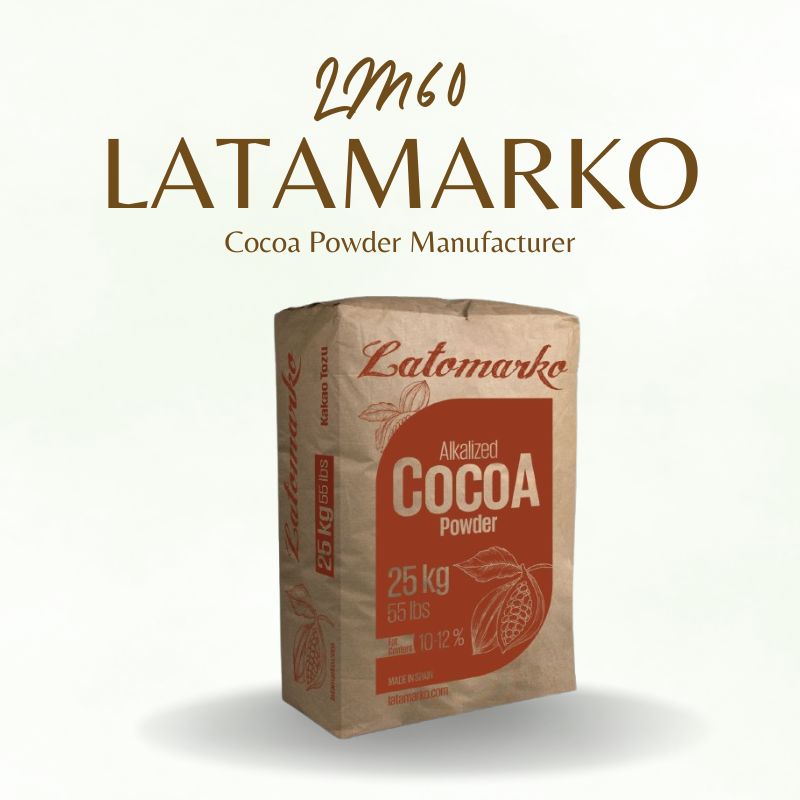

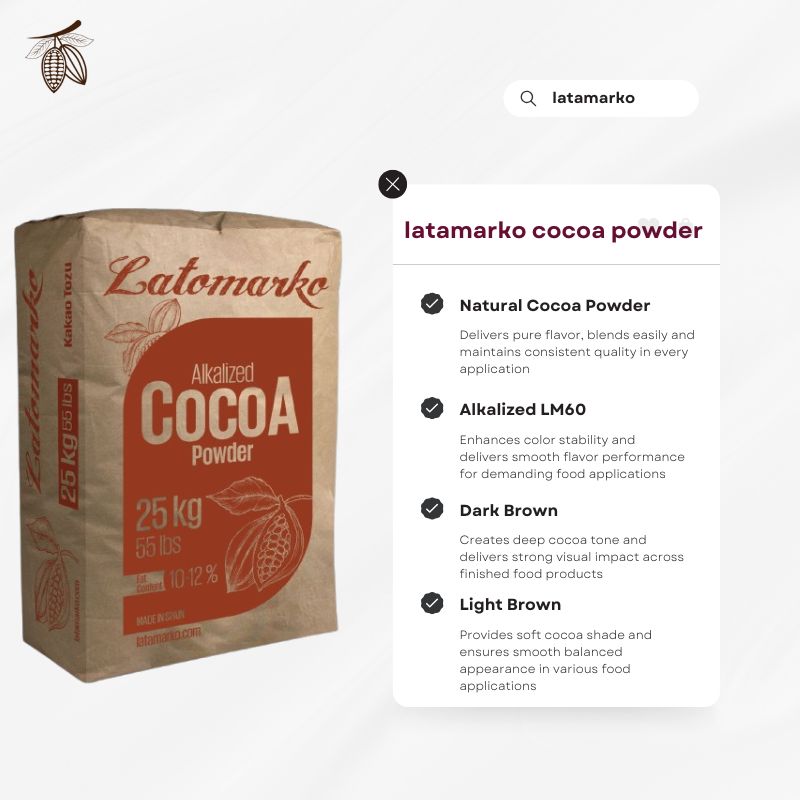

LATAMARKO is not a trading label. It is a production-driven cocoa brand developed with Spanish cocoa expertise and manufactured for global markets by MT ROYAL in TÜRKIYE. This structure allows LATAMARKO to control every stage of the cocoa value chain — from raw material sourcing and roasting to alkalization, milling, and final quality verification. Full production control is the foundation of long-term cost stability and consistent product performance.

One of the most critical challenges in the cocoa market is price volatility. Cocoa bean fluctuations, energy costs, freight instability, and regulatory pressures can disrupt supply and inflate costs. LATAMARKO addresses these challenges through long-term supplier partnerships, optimized production planning, and scalable capacity management. These systems allow LATAMARKO to offer predictable delivery schedules and more stable alkalized cocoa powder price structures for its customers.

Technical reliability is another decisive advantage. LATAMARKO maintains strict internal quality protocols that ensure uniform fat content, controlled alkalization levels, consistent color development, and precise moisture and pH balance. This level of consistency protects manufacturers from costly reformulations, production delays, and quality deviations that directly affect profitability.

Beyond production, LATAMARKO’s global logistics network and export expertise provide buyers with complete supply security. Documentation accuracy, regulatory compliance, and shipment coordination are managed by experienced export professionals, reducing operational risk and protecting business continuity.

Most importantly, LATAMARKO operates with a partnership philosophy. Rather than focusing on transactional sales, the brand invests in building long-term cooperation with its customers. This approach enables joint planning, volume optimization, and price stabilization strategies that help buyers maintain competitive product pricing in their own markets.

For companies seeking dependable quality, stable alkalized cocoa powder price, and long-term commercial growth, LATAMARKO is not simply a supplier — it is a strategic production partner

How to Avoid Overpaying for Alkalized Cocoa Powder

For buyers operating in competitive food manufacturing markets, controlling alkalized cocoa powder price is essential for maintaining healthy profit margins. However, many companies unknowingly overpay for cocoa powder due to structural mistakes in sourcing strategy, supplier selection, and contract management.

The most common reason buyers overpay is purchasing through layered trading chains. Each intermediary adds markup without adding technical value, inflating the final cost while reducing transparency. Sourcing directly from a true manufacturer eliminates unnecessary margins and gives buyers access to stable factory-level pricing.

Another costly mistake is negotiating on price without locking technical specifications. When fat content, alkalization level, color class, moisture limits, and pH tolerances are not precisely defined, suppliers deliver inconsistent batches that force production adjustments and recipe corrections. These hidden operational costs often exceed any short-term savings from a lower initial quotation.

Buyers also overpay when they treat alkalized cocoa powder as a short-term purchase instead of a strategic supply investment. Spot buying exposes companies to market volatility, shipping fluctuations, and sudden price spikes. Long-term supply planning stabilizes costs and creates leverage for better factory-level pricing conditions.

Logistics inefficiencies further inflate alkalized cocoa powder price. Poor shipment scheduling, incorrect packaging formats, and rushed transport decisions increase freight expenses and create delivery disruptions. Structured logistics planning transforms volatile supply chains into predictable cost systems.

Finally, companies overpay when they ignore quality risk. Lower-priced cocoa powder with unstable color, inconsistent solubility, or improper moisture control generates product defects, customer complaints, and brand damage. The real cost of poor quality always exceeds the initial purchase price difference.

Successful buyers focus not on the cheapest quotation, but on total value: quality stability, technical reliability, supply continuity, and long-term cost control. This approach is the most effective way to protect profitability in the global cocoa market

LATAMARKO Cocoa Powder: Spanish Expertise with Global Manufacturing Power

In the global cocoa industry, true product value is created where deep technical knowledge meets industrial production strength. LATAMARKO Cocoa Powder represents exactly this balance — combining refined Spanish cocoa expertise with large-scale global manufacturing power operated by MT ROYAL in TÜRKIYE.

Spain has long been recognized as a center of cocoa processing innovation, with strong traditions in roasting profiles, alkalization precision, and flavor development. LATAMARKO is built upon this heritage, transferring decades of Spanish know-how into a modern industrial production system designed for high-volume international supply. This combination allows LATAMARKO to deliver consistent product performance, controlled cost structures, and dependable quality that professional food manufacturers require.

At the manufacturing level, MT ROYAL operates advanced processing lines in TÜRKIYE that manage the complete cocoa transformation process — from raw bean selection and roasting to alkalization, milling, moisture control, and final product stabilization. Full vertical integration ensures that LATAMARKO cocoa powder maintains uniform specifications across every shipment, protecting buyers from costly formulation adjustments and production disruptions.

For buyers monitoring alkalized cocoa powder price, this integration is critical. Production efficiency, energy optimization, and precise process control allow LATAMARKO to stabilize costs even during periods of global cocoa market volatility. Instead of reacting to price fluctuations, LATAMARKO partners with customers to build long-term pricing models that support predictable business planning.

Beyond production, LATAMARKO’s export infrastructure provides global reach and operational reliability. Strict quality protocols, regulatory compliance, and professional logistics coordination allow customers to receive consistent product quality across continents, with reduced risk and improved cost efficiency.

LATAMARKO is not simply a cocoa supplier. It is a production-driven brand designed to support the long-term growth of manufacturers who demand stable quality, controlled alkalized cocoa powder price, and strategic supply partnerships

Inside LATAMARKO Production: From Cocoa Bean Selection to Final Quality Control

The performance of cocoa powder in industrial production begins long before the final product reaches the factory floor. At LATAMARKO, every stage of production is engineered to protect quality, control cost, and guarantee consistency — the three pillars that define long-term supply success in the cocoa industry.

The process starts with cocoa bean selection. LATAMARKO sources cocoa beans from carefully evaluated origins known for stable fermentation quality, predictable fat behavior, and strong flavor potential. Each incoming shipment is analyzed for moisture content, fermentation level, contamination risk, and processing suitability. Only beans that meet strict internal specifications enter the LATAMARKO production system.

Next comes precision roasting, where time and temperature curves are optimized to develop the desired cocoa aroma while preserving structural integrity. Roasting profiles are customized according to the final product grade — light, reddish, dark, or black — ensuring that each cocoa powder type achieves its targeted color and flavor profile with minimal variance.

During the alkalization phase, LATAMARKO applies advanced process control to manage pH transformation, color development, and solubility enhancement. Reaction conditions are continuously monitored to maintain uniform alkalization levels, preventing the instability that often leads to inconsistent batches and increased operational cost.

The subsequent milling and particle size control stage ensures smooth texture, excellent dispersion, and stable flow behavior across all applications. This precision is essential for chocolate, bakery, beverage, and dairy formulations where processing efficiency and product appearance are critical.

Before packaging, LATAMARKO performs comprehensive final quality control. Each batch undergoes laboratory testing for moisture, pH, fat content, microbiological safety, color intensity, and solubility performance. Only products that fully comply with LATAMARKO’s technical standards are approved for shipment.

This rigorous production structure enables LATAMARKO to deliver uniform product performance across all markets, while supporting stable alkalized cocoa powder price for its customers. By controlling every variable from raw material input to finished goods, LATAMARKO protects manufacturers from production disruptions, cost volatility, and quality risk.

LATAMARKO’s production philosophy is simple: when quality is controlled at every stage, profitability follows

How LATAMARKO Helps Buyers Stabilize Alkalized Cocoa Powder Cost Long-Term

One of the greatest challenges facing food manufacturers today is maintaining stable production costs in a volatile global cocoa market. For companies that closely monitor alkalized cocoa powder price, long-term cost stability is no longer a luxury — it is a necessity for survival and growth. This is where LATAMARKO delivers measurable strategic value.

LATAMARKO approaches supply partnerships with a long-term perspective. Instead of reacting to short-term market movements, the brand builds structured production and sourcing models that protect customers from sudden cost spikes. Through integrated procurement planning, LATAMARKO secures raw materials in advance, optimizes energy usage, and balances production capacity to minimize exposure to global price fluctuations.

At the manufacturing level, LATAMARKO’s full production control allows for precise forecasting of production costs. By managing roasting profiles, alkalization parameters, moisture control, and yield efficiency in-house, LATAMARKO eliminates the unpredictability that typically inflates alkalized cocoa powder price over time.

LATAMARKO also works directly with customers to develop customized supply programs. Volume-based agreements, scheduled production cycles, and synchronized logistics planning reduce inventory risk and stabilize cash flow for both parties. This collaboration transforms purchasing from a transactional process into a strategic partnership focused on sustainable growth.

Beyond operations, LATAMARKO’s global logistics network and export expertise further protect buyers from hidden costs. Accurate documentation, regulatory compliance, and reliable delivery scheduling minimize delays, penalties, and unexpected expenses that often disrupt long-term cost planning.

Most importantly, LATAMARKO invests in transparency. Buyers receive clear communication on cost drivers, market trends, and production planning, enabling them to forecast future alkalized cocoa powder price movements with greater confidence.

Through technical discipline, operational integration, and partnership-driven supply models, LATAMARKO empowers manufacturers to stabilize costs, protect margins, and compete more effectively in demanding global markets

FAQ Section Featured Snippet

1. What is alkalized cocoa powder?

Alkalized cocoa powder is cocoa processed with alkaline solution to improve color, flavor, solubility, and processing stability.

2. Why is alkalized cocoa powder price higher than natural cocoa?

Because alkalization requires additional processing, energy, quality control, and specialized equipment.

3. What affects alkalized cocoa powder price the most?

Bean origin, fat content, alkalization level, color class, moisture, pH, certifications, and logistics costs.

4. What is the difference between alkalized and natural cocoa powder?

Alkalized cocoa has smoother flavor, darker color, better solubility, and more stable performance.

5. Which alkalized cocoa color is most expensive?

Black cocoa powder is usually the most expensive due to complex processing and strict quality control.

6. What fat content is best for industrial cocoa powder?

10-12 percent is the most common for chocolate, bakery, and beverage production.

7. What moisture level is ideal for alkalized cocoa powder?

Between 2.8 and 4.0 percent for best shelf life and processing stability.

8. What pH range is normal for alkalized cocoa powder?

Typically between 6.8 and 8.5 depending on color grade.

9. Does higher fat cocoa cost more?

Yes, higher fat content increases production cost and final price.

10. How can buyers get factory-level alkalized cocoa powder price?

By purchasing directly from manufacturers and establishing long-term supply agreements.

11. Why do alkalized cocoa powder prices fluctuate?

Due to cocoa harvest changes, energy costs, freight volatility, and global market demand.

12. Is cheap alkalized cocoa powder risky?

Yes, low prices often indicate unstable quality, high moisture, and poor processing control.

13. What certifications should cocoa powder have?

ISO, HACCP, Halal, Kosher, and full traceability documentation.

14. How long is alkalized cocoa powder shelf life?

Typically 24 months under proper storage conditions.

15. Which industries use alkalized cocoa powder most?

Chocolate, bakery, beverage, dairy, confectionery, and ice cream industries.

16. Does alkalized cocoa improve product appearance?

Yes, it provides deeper, more uniform color and stable visual quality.

17. Can alkalized cocoa reduce production cost?

Yes, through improved processing efficiency and reduced waste.

18. What packaging is best for cocoa powder export?

25 kg multi-layer kraft bags with PE inner liner are standard for export.

19. How to store alkalized cocoa powder correctly?

In a cool, dry place below 25°C with humidity under 65 percent.

20. Why choose LATAMARKO for alkalized cocoa powder?

Because LATAMARKO offers stable quality, factory-direct pricing, long-term supply security, and full technical support.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

The Best Supplier of Alkalized Cocoa Powder in Türkiye

No comment