Imagine you’re overseeing a large-scale confectionery line: ovens firing, mixers humming, and silos of raw materials feeding your production floor. One ingredient might seem small, almost secondary—but in reality, it can make or break your product: cocoa powder. Not just any cocoa powder, but black cocoa powder, prized for its intense color, unique flavor, and functional properties in industrial applications.

For manufacturing facilities in Europe, the Middle East, and Asia, sourcing black cocoa powder wholesale from Türkiye has become increasingly strategic. Türkiye has developed a robust cocoa processing sector, offering reliable logistics, competitive pricing, and quality control that aligns with modern industrial requirements.

At MT Royal, we’ve seen factories save significant costs, reduce downtime, and improve product aesthetics by working with trusted Turkish suppliers while maintaining a premium segment via European brands like Latamarko. In this article, we’ll provide a complete roadmap for industrial buyers: from fundamentals and production insights to sourcing strategies, supplier evaluation, risk mitigation, and real-world applications. By the end, you’ll know exactly how to integrate black cocoa powder into your production efficiently and reliably.

What Is Black Cocoa Powder?

Fundamentals and Production

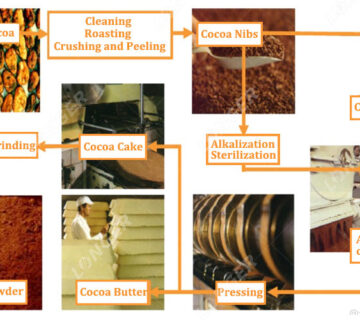

Black cocoa powder is a highly alkalized cocoa powder, typically processed using the Dutch process. This involves treating the cocoa with an alkalizing agent such as potassium carbonate to neutralize acidity. The process results in:

- Deep, dark color (almost black)

- Mellow, less acidic flavor

- Improved solubility in liquids

- Better blending with dry ingredients

Industrial-grade black cocoa powder differs from retail-grade varieties in particle size, fat content, and consistency. While a standard cocoa powder may have variable particle sizes, black cocoa powder for industrial use is sieved and graded to precise tolerances, ensuring it flows consistently through hoppers, conveyors, and mixers.

Applications in Manufacturing

Black cocoa powder is widely used in:

- Confectionery products: cookies, brownies, chocolate coatings

- Baked goods: black velvet cakes, specialty pastries

- Beverages: high-end cocoa drinks, mixes, and instant powders

- Ice cream and dairy products: to provide dark coloration without overpowering flavor

Its strong visual impact makes it especially desirable in products where appearance and uniformity are critical. In a factory setting, small differences in particle size or alkalization can affect texture, blending, and even shelf-life.

Why Manufacturers Should Source From Türkiye

Strategic Location and Logistics

Türkiye sits at the crossroads of Europe, Asia, and the Middle East, making it an ideal hub for exporting cocoa derivatives. Ports like İzmir, Mersin, and Istanbul provide efficient sea freight access to Europe, while road and rail links facilitate timely delivery across the region.

Competitive Cost Advantage

Turkish exporters often operate with lower overhead compared to Western Europe, allowing competitive pricing without compromising quality. Bulk purchases can yield significant economies of scale, reducing your cost per kilogram and improving production margins.

Quality Control and Experience

Turkey’s domestic chocolate and confectionery industry is mature, ensuring that exporters are familiar with industrial-grade specifications. Many Turkish facilities implement:

- HACCP and ISO 22000 standards

- Lot tracking and batch testing

- Controlled storage for hygroscopic powders

At MT Royal, we regularly audit suppliers in Türkiye to ensure they meet these industrial standards.

Supplier Flexibility

Turkish exporters often provide customized specifications for particle size, alkalization, and fat content. This flexibility is crucial for factories with specialized production lines or unique product formulations.

Key Considerations for Industrial Procurement

Sourcing black cocoa powder for manufacturing is not simply a matter of choosing the cheapest supplier. Missteps can lead to:

- Production downtime

- Product inconsistency

- Increased scrap rates

- Failed audits

Below are some critical pitfalls:

1. Overemphasizing Cost

While low cost may seem attractive, it can mask issues such as variable particle size, inconsistent alkalization, or elevated moisture content. The result? Caking in hoppers, inconsistent blends, or even compromised flavor.

2. Ignoring Lead Time and Logistics

Even though Türkiye is geographically advantageous, shipping bottlenecks, port congestion, and customs delays can impact delivery. Industrial buyers should plan for 8–12 week lead times, including sampling, quality verification, and shipment.

3. Neglecting Storage Requirements

Black cocoa powder is hygroscopic, meaning it absorbs moisture from the environment. Improper storage at either the supplier or factory can lead to agglomeration, clumping, or microbial contamination.

4. Inadequate Quality Verification

Batch-to-batch consistency is vital. Always verify:

- Fat content

- Alkalization level

- Particle size distribution

- Microbial load

- Heavy metals (Pb, Cd)

- Mycotoxin levels

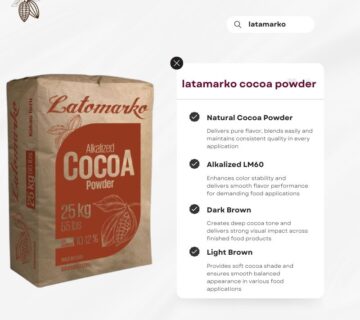

Premium European brands like Latamarko often offer tighter specifications, making them ideal for high-margin or premium product lines.

Step-by-Step Sourcing Guide for Factory Managers

Step 1: Define Your Material Specifications

- Determine fat content, alkalization level, particle size, and color intensity required.

- Consider the processing tolerance of your equipment (e.g., mixers, conveyors, sieves).

Step 2: Identify and Vet Suppliers

- Review HACCP/ISO 22000 certifications

- Inspect storage and handling procedures

- Confirm the supplier’s ability to meet large-volume demands

At MT Royal, we always vet suppliers thoroughly, ensuring consistent lot-to-lot quality for our industrial clients.

Step 3: Request Samples and Pilot Tests

- Conduct laboratory tests on incoming batches

- Run small-scale trials in your production line to assess flowability, blending behavior, and color consistency

Step 4: Calculate Total Landed Cost

Include:

- FOB price

- Freight and shipping

- Customs duties and taxes

- Storage and handling

- Buffer stock cost

Sometimes a slightly higher unit cost with better reliability (e.g., premium European suppliers like Latamarko) is more economical overall.

Step 5: Establish Inventory Buffers

- Maintain 4–6 weeks of stock to avoid production stoppages

- Ensure proper storage: cool, dry, low-humidity environment

Step 6: Monitor Supplier KPIs

Track:

- % of shipments on time

- Deviation in specifications

- Production impact (downtime, scrap)

This ensures continuous improvement and supply chain reliability.

Industry-Specific Considerations for Large-Scale Production

- Dust control: Black cocoa powder is fine; dust can trigger explosion risks in silos and hoppers. Use proper extraction systems.

- Conveying and storage: Evaluate whether your line uses big-bag silos or pneumatic conveyance, and ensure suppliers can accommodate.

- Blend stability: Consistent fat and moisture content prevents uneven mixing with sugar, milk, or flavorings.

- Supply chain seasonality: Turkey imports over 120 million kg of cocoa beans annually, so upstream risks remain. Dual sourcing helps mitigate this.

- Quality segmentation: Standard Turkish bulk for regular lines, Latamarko for premium products.

Real-Life Industrial Anecdote

A confectionery factory in Eastern Europe switched to a Turkish exporter to reduce costs. Initial shipments were fine, but by the third lot, particle size and moisture levels exceeded tolerances, causing hopper bridging and 48 hours of downtime.

Solution implemented:

- Pre-shipment quality checks

- Dual-supplier strategy (Turkey + European premium)

- Buffer inventory of 6 weeks

- Penalty clauses for deviation beyond spec

The result: improved reliability, minimal downtime, and a consistent product line.

Comparison Table: Turkish Bulk vs Premium European Brands

| Feature | Turkish Bulk Black Cocoa Powder | Premium European (Latamarko) |

|---|---|---|

| Unit Cost | Lower | Higher |

| Lead-Time | Moderate, variable | Predictable, slightly longer |

| Specification Consistency | Good but may vary | Very tight |

| Packaging Options | Big-bag, bulk | Custom packaging available |

| Ideal Product Tier | Standard lines | Premium / high-margin products |

| Risk of Downtime | Moderate | Low |

| Supplier Flexibility | Good | Limited but high-quality |

Frequently Asked Questions (FAQ)

Q1: What’s the difference between black cocoa powder and regular cocoa powder?

A1: Black cocoa powder is highly alkalized, with a darker color and milder flavor, ideal for premium confectionery applications.

Q2: How should black cocoa powder

be stored?

A2: In a cool, dry, low-humidity warehouse, away from direct sunlight and strong odors. Use sealed containers or big-bag silos.

Q3: Can black cocoa powder replace regular cocoa powder 1:1 in recipes?

A3: Not always. Due to its alkalization and intense color, you may need recipe adjustments to balance flavor, sweetness, and acidity.

Q4: Why consider European brands like Latamarko?

A4: For premium product lines requiring tight tolerances, stable color, and consistent flavor profile.

Q5: How can MT Royal help manufacturers?

A5: We provide comprehensive sourcing solutions, quality verification, competitive pricing, and access to both Turkish bulk and European premium cocoa powder brands.

Conclusion

Sourcing black cocoa powder wholesale in Türkiye is both a strategic and practical decision for modern manufacturers. The combination of competitive pricing, quality control, and supply chain reliability makes Turkey a leading hub for industrial cocoa.

By defining precise specifications, vetting suppliers, monitoring quality, and implementing buffer strategies, factory managers can reduce downtime, optimize production, and enhance product aesthetics.

In our experience at MT Royal, manufacturers benefit from a balanced approach: Turkish bulk for cost-efficiency, paired with European premium brands like Latamarko for top-tier applications. Investing in proper sourcing and quality verification today ensures smoother production tomorrow—because in industrial manufacturing, every ingredient counts.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

No comment