In modern confectionery, bakery, and cosmetic production, cocoa butter substitute oil has become a key ingredient for manufacturers seeking consistent quality, cost-efficiency, and supply chain flexibility. While traditional cocoa butter offers unique flavor and mouthfeel, its volatility in pricing and limited availability have driven production managers to explore alternative oils that replicate its functional properties.

At MT Royal, we provide manufacturers with a broad selection of cocoa butter substitute oils, ensuring competitive pricing and reliable delivery. Premium European options like Latamarko offer advanced performance, ideal for high-speed industrial lines. This article explores definitions, applications, sourcing strategies, and practical advice for factory managers, production supervisors, and procurement officers.

Understanding Cocoa Butter Substitute Oil

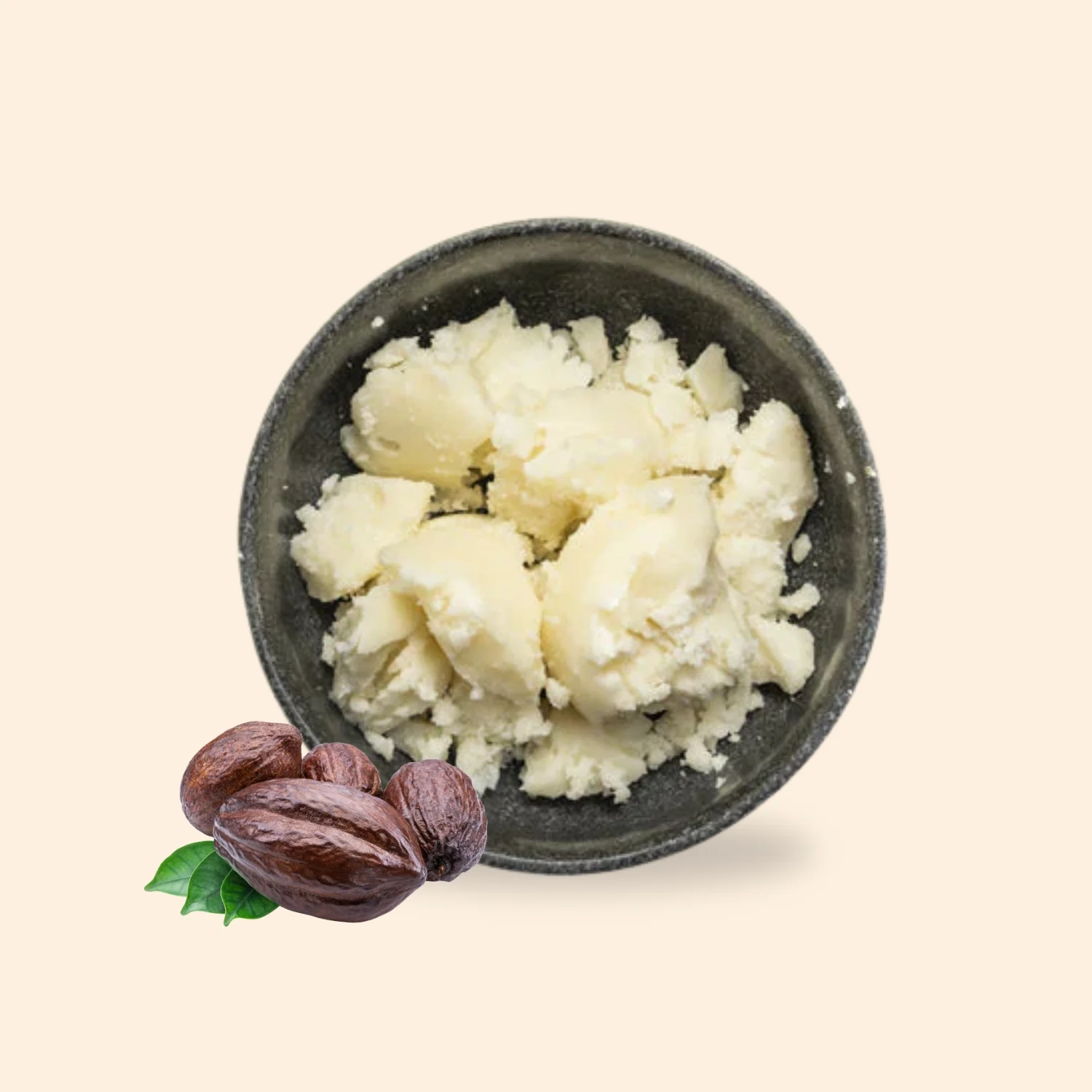

Cocoa butter substitute oil (CBSO) refers to vegetable-based or engineered fats designed to mimic the physical, chemical, and sensory characteristics of cocoa butter. These oils are widely used in chocolate, confectionery, bakery, and cosmetics.

Types of Cocoa Butter Substitute Oils

- Vegetable Fats – Derived from palm, shea, sal, kokum, or illipe.

- Fractionated Fats – Customized blends targeting specific melting points.

- Interesterified or Hydrogenated Blends – Engineered oils optimized for industrial processes.

Benefits for Manufacturing Facilities

- Cost Control: CBSO is generally more affordable than pure cocoa butter.

- Stability: Resistant to fat bloom, high temperatures, and humidity.

- Customizable Properties: Melting points and crystallization can be engineered.

- Sustainability: Traceable sources reduce environmental impact.

Industrial Applications

Chocolate Production

CBSO helps prevent fat bloom and maintain texture consistency in enrobed, molded, and compound chocolates. High-speed production lines benefit from predictable crystallization patterns.

Bakery and Confectionery

Substitute oils provide uniform texture in pastry fillings, coatings, and frostings. They support longer shelf life and better handling under variable environmental conditions.

Cosmetics and Pharmaceuticals

CBSO can replicate cocoa butter’s emollient qualities in lotions, balms, and topical formulations. Some oils offer improved oxidative stability, extending product shelf life.

Common Challenges in Using Cocoa Butter Substitute Oil

- Flavor Profile Variations – Certain vegetable oils can subtly affect taste.

- Temper Requirements – CBSO may require adjusted tempering curves.

- Supply Consistency – Bulk procurement from multiple suppliers may introduce variability.

We’ve seen many Turkish factories benefit from technical consultations with MT Royal, ensuring proper selection and testing before full-scale production.

Selecting the Right Cocoa Butter Substitute Oil

When evaluating oils, consider:

- Melting Point – Critical for mouthfeel and processing compatibility.

- Polymorphic Stability – Prevents fat bloom and textural defects.

- Compatibility with Ingredients – Must work seamlessly with cocoa solids, emulsifiers, and lecithin.

- Certifications – RSPO, organic, or fair trade certifications may be required for specific markets.

Premium Options: Latamarko and European Suppliers

While local or regional oils provide solid performance, Latamarko and other European suppliers offer:

- Precision Engineering – Oils optimized for high-speed tempering and molding.

- Consistency – Minimal batch-to-batch variation.

- Extended Shelf Life – Reduces inventory loss and production downtime.

By combining standard substitutes sourced through MT Royal with premium oils like Latamarko, manufacturers gain flexibility, cost-efficiency, and superior product quality.

Step-by-Step Guide to Procuring Cocoa Butter Substitute Oil

Step 1: Define Production Needs

- Required fat composition and melting characteristics

- Volume and packaging (bulk FIBC bags or blocks)

- Certification or traceability requirements

Step 2: Identify Suppliers

- Local manufacturers for cost-effective options

- European premium suppliers for high-performance lines

Step 3: Review Technical Data Sheets

- Fatty acid profile

- Moisture content

- Compatibility with production processes

Step 4: Conduct Pilot Runs

- Confirm tempering, texture, and bloom resistance

- Adjust formulations as needed

Step 5: Negotiate Supply Terms

- Pricing, bulk discounts, and delivery schedules

- Quality assurance and technical support

Industrial Considerations for Large-Scale Production

- Storage Conditions – Maintain 18–22°C to preserve crystallization properties.

- Blending Practices – Combine substitute oils with cocoa butter for flavor and texture optimization.

- Quality Control – Routine testing ensures consistent performance.

- Supply Chain Risk – Multiple suppliers mitigate disruption risks, especially during peak demand.

Comparison Table: Cocoa Butter vs. Substitute Oils

| Feature | Cocoa Butter | Standard CBSO | Premium CBSO (Latamarko) |

|---|---|---|---|

| Cost | High | Lower | Moderate-High |

| Melting Point Control | Natural | Adjustable | Optimized |

| Shelf Stability | Moderate | High | Very High |

| Line Compatibility | Standard | Moderate | High-speed |

| Flavor Neutrality | Excellent | Variable | Excellent |

FAQs for Procurement Managers

Q1: Can CBSO fully replace cocoa butter?

A: Yes, in most industrial applications, though premium products may still use partial cocoa butter.

Q2: Are substitute oils certified?

A: Leading suppliers, including MT Royal, provide traceable, RSPO-certified oils.

Q3: How do I blend standard and premium oils?

A: Small pilot trials determine optimal ratios for texture, tempering, and shelf life.

Q4: How can MT Royal help?

A: We provide sourcing, technical guidance, logistics coordination, and quality support for large-scale production.

Real-World Insights

- An İzmir chocolate manufacturer improved production efficiency by 18% after integrating a premium CBSO blend from Latamarko.

- A bakery in Ankara extended shelf life by 25% using cost-effective, traceable substitute oils supplied by MT Royal.

Future Outlook

The industrial market for cocoa butter substitute oils is expanding due to:

- Increasing cocoa prices and supply volatility

- Rising demand for sustainable and traceable fats

- Innovations in fat engineering for high-speed production

Factories that strategically integrate standard and premium substitute oils can achieve operational efficiency, superior product quality, and sustainability goals.

Conclusion

Cocoa butter substitute oils have evolved far beyond simple cost-saving measures—they are now essential strategic tools in modern industrial production. Their role extends from maintaining consistent texture and mouthfeel in chocolates and confectionery to enhancing shelf life, optimizing tempering processes, and ensuring smooth operation on high-speed production lines. By combining reliable sourcing through MT Royal with premium options such as Latamarko, manufacturers gain access to oils that offer precision, stability, and consistent quality, allowing for both standard and high-end product lines to thrive simultaneously.

Beyond operational efficiency, these substitutes support broader business objectives, including sustainability, traceability, and compliance with industry standards like RSPO certification. They empower production managers to mitigate supply chain risks, reduce production downtime, and achieve predictable cost structures—all while meeting consumer expectations for high-quality, consistent products.

Ask yourself: Is your production line truly leveraging cocoa butter substitute oils to their full potential—optimizing efficiency, controlling costs, maintaining consistent product quality, and supporting long-term sustainability goals? For manufacturers who approach substitute oils strategically, these ingredients can transform the way your factory operates, giving you a competitive edge in both domestic and international markets.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

No comment