Türkiye’s manufacturing sector has seen remarkable growth over the last decade, with food processing and confectionery production emerging as two of its most dynamic industries. Behind every successful chocolate bar, biscuit coating, or instant drink mix lies one quiet yet essential ingredient — cocoa powder.

Finding the right cocoa powder distributors in Türkiye isn’t just a matter of price. For production managers, procurement officers, and factory owners, it’s about quality consistency, supply reliability, and long-term cost-efficiency. A reliable distributor becomes part of the production ecosystem, ensuring that ingredient integrity remains stable across every batch, shift, and season.

At MT Royal, we’ve worked closely with manufacturing facilities across Türkiye and beyond, supplying a wide range of cocoa-based ingredients for industrial use. Through our experience, we’ve seen how the right cocoa powder — sourced through the right partner — can enhance not only flavor and texture but also yield, efficiency, and product uniformity.

What Makes a Cocoa Powder Distributor Truly Reliable?

A good distributor does more than deliver pallets. They act as a strategic supply partner — offering stable sourcing, technical documentation, and support that aligns with food manufacturing standards.

Here are the core attributes manufacturers look for when evaluating distributors in Türkiye:

- Consistent Quality Control: Industrial buyers need batch-to-batch uniformity, supported by certificates of analysis (COA) and microbiological testing.

- Global Brand Access: The ability to offer European, Asian, and Latin American brands — from economy to premium.

- Technical Support: Guidance on product application, solubility, and fat content compatibility with existing formulations.

- Scalable Logistics: Efficient cold-chain or ambient storage and timely deliveries across Türkiye’s manufacturing zones (İstanbul, İzmir, Gaziantep, Konya, Bursa).

- Regulatory Compliance: Alignment with Turkish Food Codex and ISO food safety standards.

In our experience, these factors directly determine whether a supplier becomes a long-term partner — or just a temporary vendor.

Understanding Cocoa Powder Grades and Industrial Uses

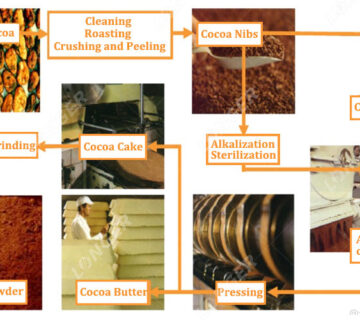

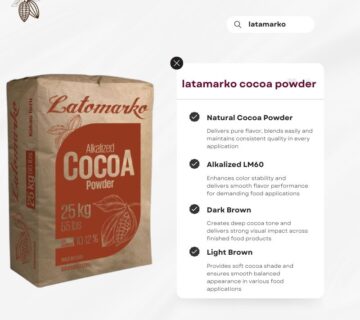

Cocoa powder for manufacturing typically falls into three main categories, each designed for specific applications in food production:

| Type | Key Features | Industrial Use |

|---|---|---|

| Natural Cocoa Powder | Light color, fruity-acidic flavor | Biscuits, light cakes, instant drinks |

| Alkalized (Dutch-processed) | Darker tone, milder flavor, improved dispersibility | Chocolate coatings, fillings, beverages |

| High-fat Cocoa Powder | 20–24% cocoa butter, rich mouthfeel | Ice cream, compound chocolate, dairy desserts |

European brands like Latamarko — a Spanish-origin premium manufacturer — have set remarkable benchmarks in terms of processing precision, color stability, and fat uniformity. Their powders are often favored by factories producing fine chocolates and bakery fillings where appearance consistency and rich flavor are critical.

Türkiye’s Cocoa Powder Distribution Network: An Evolving Supply Chain

Türkiye serves as a strategic bridge between Europe and Asia, giving it access to both Western manufacturing standards and competitive import channels from African and Southeast Asian cocoa origins.

Today’s cocoa powder distributors in Türkiye are evolving from traditional traders into technical supply partners. They not only import and distribute but also assist factories with formulation advice, cost-per-unit optimization, and custom packaging sizes suited for industrial dosing systems.

At MT Royal, we’ve seen this transformation firsthand. Many of our partners now prioritize distributors who can support them with:

- Custom blends (e.g., 10–12% vs. 20–22% fat)

- Reduced microbial count for sensitive applications

- Continuous product availability to avoid downtime

- Transparent sourcing aligned with sustainability programs

This evolution reflects a growing maturity in Türkiye’s food manufacturing ecosystem — one that values reliability and traceability as much as flavor.

Key Considerations for Factory Procurement Managers

When choosing a cocoa powder distributor, procurement managers often face several recurring challenges. Let’s explore them — and how to mitigate the risks.

A. Quality vs. Price Dilemma

While price pressures are real, the lowest-cost cocoa powder may result in inconsistent viscosity, off-flavors, or poor dispersibility. A cheaper option that compromises quality can lead to downtime, reworks, and even product recalls — all far more costly than premium ingredients.

Tip: Evaluate suppliers based on total operational cost, not just the per-kilo price. Ask for COA documentation and check particle size distribution and moisture levels.

B. Supply Chain Reliability

A frequent pain point in Türkiye’s industrial sector is supply interruption due to port congestion or customs delays. Partnering with a distributor that maintains local warehousing and inventory can prevent line stoppages.

At MT Royal, we maintain relationships with multiple ports and logistics hubs to minimize such disruptions, ensuring steady deliveries even during high-demand seasons.

C. Regulatory and Safety Compliance

For export-oriented manufacturers, compliance is non-negotiable. Ensure that the distributor provides:

- Halal and Kosher certifications

- Heavy metal and aflatoxin test results

- Traceability from bean to powder

Brands like Latamarko exemplify European compliance standards, making them a preferred choice for factories targeting international markets.

Comparing Local and Imported Cocoa Powder Distributors

| Aspect | Local Distributors (Türkiye-based) | Imported / European Brands (e.g., Latamarko) |

|---|---|---|

| Lead Time | Fast, local availability | Slightly longer, depending on shipment schedules |

| Cost Range | Lower to mid-tier | Premium pricing, higher consistency |

| Quality Consistency | Variable | Exceptionally stable |

| Technical Support | Limited | Comprehensive, application-driven |

| Best for | General confectionery, bakery | High-end chocolate, dairy, and export production |

Factories often find value in using a hybrid approach — sourcing bulk from local distributors for standard production and complementing with premium imported cocoa for flagship products.

How Cocoa Powder Impacts Production Efficiency

Few procurement teams realize how much cocoa powder characteristics influence production performance:

- Flowability: Impacts dosing accuracy and speed.

- Solubility: Affects blending in beverage lines or cream fillings.

- Color Stability: Ensures product visual consistency across batches.

- Fat Content: Directly influences viscosity and spreadability in chocolate compounds.

Even minor deviations can cause downstream challenges — from pump clogging to uneven baking coloration. That’s why top manufacturers collaborate with distributors capable of offering technical advice and custom formulations aligned with their machinery and processes.

Sustainable and Ethical Cocoa Sourcing in Türkiye’s Market

Sustainability has shifted from a marketing term to a procurement requirement. Global food brands operating in Türkiye increasingly demand traceability from cocoa origin to final product.

European-origin brands like Latamarko have taken leadership roles in this transition, focusing on:

- Certified sustainable cocoa sourcing

- Transparent supply chains

- Environmentally responsible processing

At MT Royal, we align with these standards, offering access to brands that respect both quality and ethical production. For manufacturers exporting to Europe, aligning with sustainable distributors isn’t just responsible — it’s strategic.

Common Pitfalls in Industrial Cocoa Powder Procurement

- Ignoring batch uniformity: Different particle sizes can affect mixing time and energy use.

- Overlooking microbiological load: High bacterial counts can cause spoilage or rejection.

- Underestimating packaging impact: Moisture ingress in large sacks can degrade powder quality.

- Not auditing suppliers: Failing to verify documentation leads to compliance risks.

Smart procurement managers now insist on pre-shipment sampling, warehouse inspections, and cross-batch analysis before approving a new distributor.

Frequently Asked Questions

Q1: What’s the typical fat percentage used in Turkish confectionery manufacturing?

Most local producers use cocoa powders with 10–12% fat, balancing cost and texture. However, premium exporters prefer 20–22% fat for superior mouthfeel.

Q2: Are all cocoa powders interchangeable in recipes?

Not entirely. pH levels and particle size affect color and solubility. Substitutions should be tested under production conditions.

Q3: How can I ensure consistent quality across multiple plants?

Work with a distributor that offers standardized SKUs and consistent batch records across shipments. MT Royal, for instance, maintains traceability and batch data for every product line.

Q4: Does Latamarko supply organic or sustainable-certified cocoa powders?

Yes. Latamarko offers both conventional and certified sustainable variants, meeting European eco-compliance standards.

Choosing the Right Distributor: Practical Steps

Here’s a quick roadmap for factory managers evaluating distributors:

- Define production needs (fat content, color, pH, certification).

- Request technical sheets and COAs.

- Evaluate logistics capabilities — warehousing, port proximity, delivery schedules.

- Conduct pilot tests using production equipment.

- Review supplier support policies for downtime or recall situations.

In our collaborations across Türkiye’s industrial food sector, we’ve seen manufacturers reduce procurement risk by building dual-source partnerships — one local, one international. It’s a strategic balance between flexibility and security.

Future Trends in Cocoa Powder Distribution

The Turkish cocoa supply chain is entering a new era driven by:

- Automation in ingredient storage and dosing

- Rising demand for clean-label cocoa products

- Preference for sustainable sourcing

- Digital procurement platforms simplifying B2B transactions

Manufacturers are also moving toward direct distributor relationships rather than third-tier traders — valuing reliability, transparency, and post-purchase technical support.

Final Thoughts

Choosing among the many cocoa powder distributors in Türkiye isn’t just about finding a supplier — it’s about building a relationship that supports production excellence. The right distributor brings stability to your formulations, confidence to your quality assurance team, and predictability to your procurement calendar.

At MT Royal, we continue to support manufacturers with access to diverse brands — from cost-effective industrial options to premium European selections like Latamarko. We’ve seen how strategic ingredient sourcing can elevate both product quality and operational efficiency, one batch at a time.

And that’s the essence of true industrial partnership — where reliability meets innovation, and quality drives performance.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

No comment