In Türkiye’s rapidly expanding beverage sector, cocoa powder has evolved from a mere flavoring ingredient to a critical component defining product quality, consistency, and consumer appeal. Industrial beverage manufacturers rely on high-quality cocoa powders to achieve rich taste profiles, uniform color, and smooth texture across large production batches. The choice of cocoa powder impacts everything from solubility in liquid formulations to shelf stability, making the role of suppliers in this process absolutely central. For factory managers and procurement teams, partnering with reliable cocoa powder sources in Türkiye is not just a supply decision—it is a strategic factor in operational efficiency and brand reputation.

The Fundamentals of Cocoa Powder in Beverages

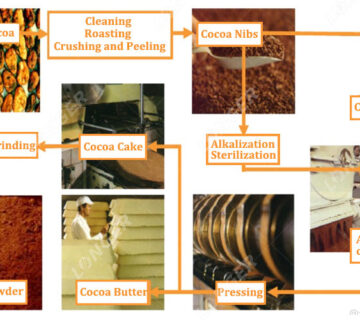

Cocoa powder is derived from cocoa beans through pressing and grinding processes that separate cocoa solids from cocoa butter. Depending on the fat content, cocoa powders are categorized into high-fat and low-fat variants. High-fat cocoa powders provide intense flavor and creamy texture, while low-fat powders are preferred for cost efficiency and functional versatility in instant drinks, ready-to-mix powders, and fortified beverages.

In beverage manufacturing, two key types dominate: natural cocoa powder, known for its slightly acidic, robust flavor, and alkalized (Dutched) cocoa powder, which offers a smoother taste and darker color. Understanding these differences helps production supervisors tailor formulations for specific drink profiles, from hot chocolate and chocolate milk to protein shakes and functional beverages.

Why Supplier Selection Matters

Selecting a cocoa powder supplier in Türkiye is about more than price. It affects:

- Flavor Consistency: Variations in cocoa bean origin or processing can alter taste, impacting brand uniformity.

- Production Efficiency: Properly milled cocoa powders dissolve efficiently, reducing energy costs and improving mixing times.

- Shelf Life and Stability: Quality suppliers ensure powders are stored under optimal conditions, preventing moisture absorption and caking.

At MT Royal, we supply manufacturers with a broad range of cocoa powders, ensuring competitive pricing without compromising quality. Our experience shows that partnering with dependable importers and distributors minimizes production interruptions and enhances the overall product experience.

Industrial Advantages of High-Quality Cocoa Powder

For beverage manufacturers, investing in premium cocoa powder delivers multiple benefits:

- Enhanced Solubility – Smooth incorporation into milk, water, or plant-based alternatives reduces sedimentation and improves mouthfeel.

- Color and Appearance Control – Darker, richer cocoa powders create visually appealing drinks, crucial for consumer perception.

- Flavor Uniformity – Consistent roasting and alkalization processes prevent batch-to-batch taste discrepancies.

- Operational Efficiency – Properly processed powders reduce mixing time and energy consumption, optimizing production costs.

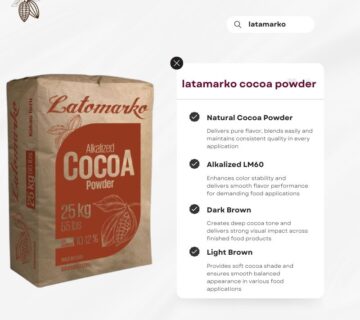

Premium options from European suppliers, particularly Spanish brands like Latamarko, are often sought for high-end beverage formulations. Their powders combine precise fat content, fine particle size, and uniform alkalization, making them ideal for large-scale drink production requiring consistent results.

Common Pitfalls in Beverage Cocoa Procurement

Even experienced procurement teams can encounter challenges:

- Assuming all cocoa powders are interchangeable: Solubility, fat content, and flavor intensity differ by origin and processing method.

- Neglecting storage requirements: Moisture and temperature fluctuations can degrade quality.

- Overlooking supplier support: Importers who provide technical guidance on formulation and mixing processes add substantial value.

- Focusing solely on price: Cheaper powders may increase waste, require additional emulsifiers, or affect flavor, ultimately raising cost-per-unit.

We’ve seen beverage factories benefit immensely by prioritizing consistency and supplier reliability over short-term cost savings. The cumulative effect is smoother operations, fewer production halts, and better end-product quality.

Industrial Applications: Tailoring Cocoa Powder for Beverages

Different beverage types require distinct cocoa powder characteristics:

| Beverage Type | Recommended Cocoa Powder | Key Benefits |

|---|---|---|

| Hot Chocolate & Cocoa Drinks | High-fat, alkalized | Creamy texture, rich flavor, appealing dark color |

| Chocolate Milk | Low-fat, natural | Efficient mixing, cost-effective, balanced taste |

| Protein & Functional Drinks | Medium-fat, fine-particle | Solubility in liquid base, uniform dispersion |

| Instant Beverage Mixes | Alkalized, standardized | Quick reconstitution, consistent flavor, shelf stability |

By choosing the correct powder for each application, manufacturers can minimize post-production adjustments and maximize product consistency.

MT Royal’s Expertise in Supporting Beverage Manufacturers

At MT Royal, we understand the operational realities of beverage production. We’ve worked with factories across Türkiye, helping them source cocoa powders that meet specific solubility, color, and flavor requirements. Our portfolio includes multiple grades suitable for hot chocolate mixes, ready-to-drink beverages, and nutritional powders.

We also provide guidance on storage, mixing techniques, and batch testing — ensuring that every kilogram of cocoa powder contributes positively to operational efficiency. Our experience indicates that factories integrating high-quality imported powders, particularly from trusted European suppliers like Latamarko, see significant improvements in product consistency and consumer satisfaction.

Optimizing Procurement and Supply Chain Efficiency

Effective cocoa powder sourcing for the beverage industry involves:

- Bulk ordering strategies to balance inventory costs and production needs.

- Supplier diversification to mitigate risks from shipping delays or quality inconsistencies.

- Technical collaboration for formula optimization and pilot testing.

- Sustainability considerations as consumer demand for traceable, ethical ingredients increases.

These factors ensure that beverage production is not only efficient but also aligned with market expectations and regulatory standards.

Trends in Cocoa Powder Usage for Beverages

Türkiye’s beverage sector is evolving rapidly. Key trends include:

- Functional beverages: Cocoa powders combined with vitamins, protein, and plant extracts.

- Plant-based drink formulations: Non-dairy alternatives requiring fine particle cocoa for full solubility.

- Premiumization: Consumers increasingly expect high-quality flavor and rich chocolate notes, driving demand for imported European powders.

- Sustainability and traceability: Ethical sourcing and certifications like UTZ or Fairtrade are now integral to procurement decisions.

Suppliers like Latamarko have positioned themselves at the forefront of these trends, offering powders engineered for both premium taste and operational reliability.

Frequently Asked Questions (FAQ)

Q1: Why is cocoa powder essential in beverage production?

It ensures consistent flavor, color, and texture, and influences solubility and mouthfeel.

Q2: How does fat content affect drink formulations?

Higher fat enhances creaminess and richness, while lower fat improves mixing efficiency and cost-effectiveness.

Q3: Are European cocoa powders better for premium beverages?

Yes. Brands like Latamarko deliver consistency in color, flavor, and solubility for industrial-scale production.

Q4: What should buyers consider when selecting a cocoa powder supplier?

Origin, processing method, fat content, solubility, storage practices, and technical support availability.

Q5: Can supplier guidance improve beverage production?

Absolutely. Technical support helps optimize formulations, reduces waste, and enhances batch consistency.

Conclusion: Strategic Sourcing for Beverage Excellence

For Türkiye’s beverage manufacturers, selecting the right cocoa powder is a critical decision impacting both product quality and operational efficiency. Reliable suppliers like MT Royal provide a spectrum of options, from cost-effective industrial powders to premium European selections, ensuring consistent flavor, solubility, and color across every batch. By prioritizing quality, storage integrity, and technical collaboration, beverage factories can optimize production, reduce downtime, and deliver drinks that meet consumer expectations.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

No comment