For confectionery manufacturers in Türkiye, cocoa powder isn’t just an ingredient—it’s a cornerstone of product quality, consistency, and brand reputation. From chocolate bars to truffles, bonbons, and bakery inclusions, the cocoa you choose directly affects flavor, texture, color, and even shelf stability.

Yet selecting the right cocoa powder is far from simple. Prices vary, quality differs among brands, and production challenges arise from inconsistent particle size, alkalization, and fat content. At MT Royal, we’ve seen first-hand how thoughtful cocoa sourcing can optimize production, reduce waste, and elevate confectionery products to premium standards. In this guide, we’ll cover pricing insights, supplier considerations, operational tips, and brand comparisons—including Latamarko, a high-quality Spanish-origin cocoa powder ideal for confectionery operations.

1-Understanding Cocoa Powder: Fundamentals for Confectionery

Cocoa powder is the dehydrated, defatted product of roasted cocoa beans. Its composition and processing determine its suitability for confectionery applications:

| Type | Characteristics | Ideal Confectionery Uses |

|---|---|---|

| Natural Cocoa | Light brown, slightly acidic, intense cocoa aroma | Truffles, cocoa dusting, baked inclusions |

| Dutch-Processed | Alkalized, darker color, smoother taste | Chocolate coatings, filled chocolates, bonbons |

| High-Fat Cocoa | 20–24% cocoa butter | Ganache, pralines, chocolate fillings |

| Low-Fat Cocoa | 10–12% cocoa butter, cost-effective | Mass-market chocolate, bakery mixes |

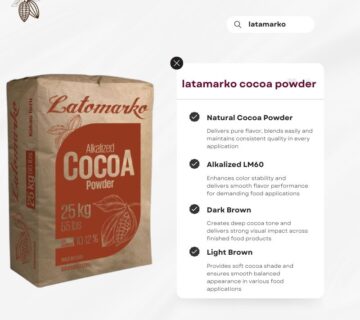

Latamarko cocoa powder stands out with precise alkalization, uniform particle size, and consistent fat content, ensuring smooth mixing and consistent final products.

2-Cocoa Powder Pricing Dynamics in Türkiye

Wholesale cocoa powder prices in Türkiye depend on multiple factors affecting both cost and performance:

| Factor | Impact on Price | Confectionery Insight |

|---|---|---|

| Bean Origin | African beans cheaper; South American/European higher | Latamarko sources select Spanish beans for consistency |

| Fat Content | Higher fat increases price | Essential for smooth ganache and enrobing |

| Processing | Dutch-processed powders cost more | Provides consistent color and taste |

| Supply Volume | Bulk orders reduce unit cost | Plan quarterly to stabilize costs |

| Currency Fluctuation | Imported powders sensitive to USD/TRY | MT Royal mitigates volatility with local stock |

| Packaging | Bulk sacks cheaper | Efficient storage lowers production overhead |

From our experience, bakeries and confectionery manufacturers benefit from predictable pricing and reliable supply, especially when partnering with trusted suppliers like MT Royal.

Why Premium Brands Like Latamarko Make a Difference

Spanish engineering has long been respected in industrial circles. Latamarko cocoa powder exemplifies:

- Consistent Color and Flavor: Ensures uniformity in enrobed chocolates and coatings.

- Fine Particle Size: Reduces clumping and facilitates smooth mixing in chocolate masses.

- Precise Alkalization: Critical for confections sensitive to pH variations.

- Reliable Shelf Life: Stable properties over extended storage.

Premium cocoa powders reduce downtime, minimize rework, and enhance consumer satisfaction in high-end confectionery.

4-Cocoa Powder Types and Applications in Confectionery

| Type | Fat Content | Processing | Best Confectionery Use |

|---|---|---|---|

| Natural | 10–12% | Non-alkalized | Dusting truffles, fillings |

| Dutch-Processed | 12–22% | Alkalized | Chocolate bars, enrobing |

| High-Fat | 20–24% | Alkalized | Ganache, pralines |

| Low-Fat | 10–12% | Non-alkalized | Mass-produced chocolate |

5-Common Procurement Challenges for Confectionery Manufacturers

Even experienced procurement teams face pitfalls:

- Batch Variation: Different lots may vary in color or flavor intensity.

- Clumping & Solubility Issues: Low-quality powders can slow down automated mixers.

- Inadequate Storage Conditions: Cocoa absorbs moisture, affecting texture and consistency.

- Focus on Price Alone: Cheap powders may lead to hidden costs in waste, rework, or downtime.

At MT Royal, we emphasize consistent supply and quality checks to mitigate these challenges.

6-Operational Tips for Confectionery Production

- Define Requirements: Consider fat content, alkalization, and particle size for each product.

- Multi-Brand Sourcing: MT Royal offers both economical and premium options, including Latamarko.

- Bulk Planning: Quarterly or semi-annual orders stabilize supply and costs.

- Proper Storage: Store under 25°C in airtight containers.

- Batch Testing: Small-scale tests prevent large-scale production failures.

Frequently Asked Questions (FAQ)

Q1. Which cocoa powder is ideal for pralines?

Dutch-processed, high-fat cocoa ensures smooth texture and proper enrobing.

Q2. How long can cocoa powder be stored?

Typically 18–24 months; premium powders like Latamarko maintain stability longer.

Q3. Does MT Royal supply multiple brands?

Yes, including top-tier European options.

Q4. Are higher-priced powders always better?

Not necessarily — consistency, solubility, and fat content are more critical.

Q5. How do we mitigate currency fluctuation risks?

MT Royal offers local inventory and bulk contracts to stabilize pricing.

Industry Trends for Cocoa Powder in Confectionery

- Ethical sourcing and traceability gaining importance.

- European-grade powders are increasingly preferred for premium chocolate products.

- Digital procurement helps factories monitor costs and inventory in real-time.

- Climate and global supply fluctuations continue to impact prices and availability.

Manufacturers planning ahead, testing premium powders, and partnering with MT Royal gain a competitive advantage in both cost efficiency and product quality.

Conclusion: Making Smart Cocoa Powder Choices

Choosing the right cocoa powder is not simply about finding the lowest price — it’s about ensuring reliability, consistency, and smooth operational performance across your confectionery production. A high-quality cocoa powder reduces waste, minimizes production errors, and guarantees that your chocolates, truffles, and ganaches maintain the same taste, color, and texture batch after batch.

Premium options like Latamarko illustrate the value of investing in quality. Their consistent particle size, controlled alkalization, and stable fat content allow confectionery manufacturers to avoid clumping, improve mixing efficiency, and achieve uniform products. For production managers, this translates into less downtime, lower rework costs, and a more predictable workflow — critical factors in large-scale manufacturing.

At the same time, partnering with a trusted supplier like MT Royal gives you access to a range of brands and grades, balancing cost efficiency with premium performance. By focusing on consistency, operational stability, and reliable sourcing, you can make informed procurement decisions that support long-term success, elevate product quality, and strengthen your brand reputation in Türkiye’s competitive confectionery market.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

Istanbul import export company

No comment