Chocolate ice cream is a staple in desserts and frozen treats, yet the secret to premium flavor, texture, and color often lies in the quality of the cocoa powder used. For industrial manufacturers, selecting the right cocoa powder for ice cream can drastically influence taste consistency, processing efficiency, and product appeal.

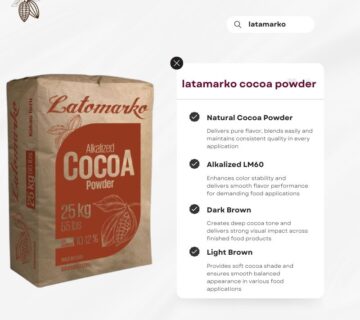

In Türkiye, manufacturers have access to a growing selection of high-quality cocoa powders, combining competitive pricing with European standards. This guide provides factory managers, production supervisors, and procurement officers with actionable insights for sourcing cocoa powder suitable for industrial ice cream production. We’ll also explore MT Royal’s offerings and highlight Latamarko, a Spanish-origin premium brand, as an example of top-tier quality in frozen dessert applications.

Understanding Cocoa Powder for Ice Cream

What Is Cocoa Powder?

Cocoa powder is derived from fermented, roasted cacao beans, from which cocoa butter is extracted. The resulting powder contains cocoa solids, the primary source of flavor, color, and functional properties. Cocoa powders for ice cream differ from general-purpose powders due to:

- Solubility and dispersibility: Ensuring smooth incorporation into dairy and non-dairy bases

- Color stability: Maintaining deep chocolate hues during freezing

- Flavor consistency: Preventing off-notes or bitterness over multiple batches

Types of Cocoa Powder in Ice Cream Manufacturing

- Natural Cocoa Powder

- Slightly acidic, robust chocolate flavor

- Ideal for artisanal-style ice creams and classic recipes

- Dutch-Processed (Alkalized) Cocoa Powder

- Neutral pH, smooth taste, darker color

- Favored in commercial ice cream for consistent color and flavor stability

- Instant or Soluble Cocoa Powder

- Designed to disperse quickly in cold or hot liquids

- Reduces mixing time in industrial-scale ice cream production

Benefits of Premium Cocoa Powder in Ice Cream Production

1. Flavor Consistency Across Batches

In our experience supplying manufacturing facilities, batch-to-batch flavor uniformity is one of the most critical factors in ice cream production. Premium powders like Latamarko-inspired products ensure predictable aroma, sweetness balance, and cocoa intensity, even in high-volume runs.

2. Enhanced Mixing and Production Efficiency

High-quality cocoa powders dissolve uniformly, minimizing clumping and sedimentation. In industrial ice cream lines, this translates into:

- Shorter mixing cycles

- Reduced strain on equipment

- Improved texture in final products

3. Color Stability in Frozen Products

Ice cream undergoes rapid freezing and storage fluctuations, which can affect color. Dutch-processed powders maintain a rich, dark chocolate hue that appeals to consumers and enhances product shelf-life.

4. Reduced Cost per Unit

While premium powders may seem costlier upfront, the benefits include:

- Fewer rejected batches due to flavor or color inconsistency

- Lower waste from clumping or uneven incorporation

- Predictable performance in large-scale automated production lines

Common Pitfalls in Industrial Cocoa Powder Procurement

- Choosing the wrong type for the application

Not all cocoa powders are optimized for frozen products. Natural powders may result in color fading or texture issues, while poorly soluble powders can create grainy ice cream. - Ignoring supplier reliability

Delays in bulk shipments can halt production. Partnering with trusted suppliers like MT Royal ensures timely deliveries and consistent quality. - Neglecting storage conditions

Cocoa powder absorbs moisture and odors. Improper storage can lead to caking, flavor loss, and microbial contamination. - Overlooking technical support

Ice cream production involves complex mixing, freezing, and stabilizer interactions. Distributors offering technical guidance reduce trial-and-error and improve production efficiency.

Step-by-Step Guide for Sourcing Cocoa Powder for Ice Cream

- Assess Production Requirements

Determine batch sizes, ice cream flavor profiles, and desired chocolate intensity. - Select Suitable Cocoa Powder Type

Consider solubility, color stability, and flavor intensity for frozen applications. - Evaluate Supplier Technical Data

Request information on particle size, fat content, alkalization, and dispersibility. - Run Pilot Trials

Test powders under actual production conditions to ensure smooth integration and consistent flavor. - Secure Bulk Supply Agreements

Negotiate pricing, delivery schedules, and batch consistency guarantees with suppliers like MT Royal. - Optimize Storage and Handling

Maintain cool, dry, and odor-free conditions with controlled humidity to prevent caking and quality degradation.

Comparison Table: Cocoa Powder Options for Ice Cream in Türkiye

| Brand / Type | Origin | Fat Content | Particle Size | Alkalization | Ideal Use | Cost Tier | Notes |

|---|---|---|---|---|---|---|---|

| Latamarko Premium | Spain | 10–12% | Fine | Dutch | Premium ice cream, frozen desserts | High | Superior flavor and color stability, ideal for export or high-end products |

| MT Royal Select | Türkiye | 11% | Medium | Dutch | Industrial ice cream, chocolate coatings | Medium | Reliable batch consistency, locally available |

| Cargill Industrial | Global | 10–12% | Fine | Natural / Dutch | Large-scale ice cream production | Medium-High | Consistent quality, technical support available |

| Local Industrial Brand | Türkiye | 8–10% | Coarse | Natural | Mass-market ice cream, economy lines | Low-Medium | Cost-effective, less intense flavor and color |

Industrial Takeaways:

- Fine, Dutch-processed powders are best for smooth texture and stable color

- Particle size affects dispersion in dairy bases and freezing consistency

- Fat content contributes to mouthfeel and creaminess

Industry Considerations for Large-Scale Ice Cream Production

- Solubility and dispersibility: Essential for high-speed mixing and reducing equipment downtime

- Flavor stability: Premium powders prevent bitterness or fading over frozen storage

- Supply chain reliability: Multiple trusted suppliers reduce production disruptions

- Storage logistics: Cocoa powder is sensitive to humidity and temperature, necessitating controlled warehousing

Real-Life Industrial Examples

- A leading Turkish ice cream factory switched to Latamarko-inspired Dutch-processed powders. Result: smoother texture, darker chocolate color, and more consistent flavor across batches.

- Factories sourcing MT Royal cocoa powder observed reduced mixing time and fewer clumping issues in high-speed production lines.

- Using reliable distributors ensures continuous supply, reducing risk of halted production during peak season.

Emerging Trends in Cocoa Powder for Ice Cream

- Functional cocoa powders enriched with antioxidants or vitamins

- Sustainable and certified sourcing (Rainforest Alliance, UTZ) appealing to eco-conscious markets

- Automation-ready fine powders for high-speed dosing and mixing

- Premium European-inspired blends, including Latamarko, enhancing product differentiation and export readiness

FAQ: Cocoa Powder for Ice Cream in Türkiye

Q1: Which type of cocoa powder is best for industrial ice cream?

Dutch-processed powders are preferred for smooth texture, color stability, and neutral pH.

Q2: How should cocoa powder be stored for frozen dessert production?

Maintain dry, cool, odor-free storage under 50% humidity in airtight containers or silos.

Q3: Can premium powders like Latamarko improve product quality?

Yes. They offer consistent flavor, color stability, and smoother incorporation in large-scale production.

Q4: Are local Turkish powders suitable for industrial ice cream production?

Yes. MT Royal provides reliable local options balancing cost and performance, suitable for high-volume production.

Strategic Takeaways for Factory Managers

- Reliable distributors reduce downtime and supply chain risk

- Premium powders improve texture, flavor, and color consistency

- Technical guidance enhances mixing efficiency and equipment longevity

- Proper storage and handling prevent waste and flavor degradation

At MT Royal, we’ve worked with numerous ice cream producers to streamline procurement, ensure batch consistency, and optimize production efficiency, helping manufacturers achieve high-quality frozen desserts consistently.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

Istanbul import export company

No comment