In Türkiye’s dynamic manufacturing sector, cocoa powder stands as one of the most essential ingredients driving the success of the confectionery, bakery, and beverage industries. For decades, Turkish manufacturers have relied heavily on imported cocoa powder to maintain consistency, flavor precision, and global competitiveness. As demand for chocolate-based products expands both domestically and internationally, understanding the ecosystem of cocoa powder importers in Türkiye becomes more than just a procurement matter — it’s a strategic necessity for every production manager and factory owner seeking operational excellence.

From the bustling production lines of Istanbul to the specialized confectionery plants of Gaziantep, cocoa powder serves as the common thread that ties innovation and tradition together. Yet behind every successful chocolate bar, biscuit, or drink mix lies the careful selection of imported cocoa powder — a process that defines the brand’s texture, color, and profitability.

Understanding the Fundamentals: Why Cocoa Powder Imports Matter

Cocoa powder importers in Türkiye serve a critical function in bridging international quality standards with local production needs. While Türkiye’s confectionery sector is globally renowned, it relies on a steady flow of raw materials sourced from countries like the Netherlands, Spain, Indonesia, and Côte d’Ivoire. These imports ensure that Turkish manufacturers can meet diverse production requirements — from high-fat cocoa powders used in premium chocolate formulations to low-fat variants ideal for baking and beverages.

Low-fat and high-fat cocoa powders differ not only in composition but also in performance. High-fat powders deliver richness and smoothness, while low-fat alternatives optimize cost-efficiency and mixing properties. For industrial buyers, the import source, brand reputation, and processing technology of the cocoa powder directly influence product quality and consumer satisfaction.

The Role of Importers in Türkiye’s Industrial Cocoa Supply Chain

Importers are more than intermediaries — they are partners in quality assurance, logistics coordination, and technical reliability. In Türkiye, leading importers have established long-term relationships with global cocoa processors, ensuring consistency in particle size, pH levels, and flavor intensity.

These suppliers handle the complexities of international shipping, customs clearance, and temperature-controlled storage — aspects that directly impact the freshness and integrity of cocoa powder. For plant supervisors and production managers, partnering with a reputable importer can eliminate the risk of supply interruptions and ensure stable production cycles, especially in high-demand seasons such as Eid, Christmas exports, and regional confectionery festivals.

At MT Royal, we’ve worked closely with food manufacturing facilities across Türkiye, helping them secure top-quality cocoa powders tailored to their production profiles. Whether it’s natural or alkalized cocoa powder, we understand how minor differences in moisture levels or fat content can transform the final product.

Factors That Define a Reliable Cocoa Powder Importer

Selecting an importer is not merely about pricing; it’s about trust, traceability, and long-term partnership. The most successful manufacturing plants in Türkiye evaluate importers based on several factors:

| Evaluation Criteria | Why It Matters | Ideal Benchmark |

|---|---|---|

| Origin of Cocoa Beans | Determines flavor profile and quality consistency | Sourced from established producers (e.g., West Africa, Latin America) |

| Processing Technology | Impacts solubility and color intensity | Advanced European milling and alkalization |

| Storage Conditions | Maintains freshness and prevents clumping | Climate-controlled warehouses |

| Quality Certification | Ensures compliance with global standards | ISO, Halal, Kosher, HACCP |

| Supply Reliability | Minimizes downtime in production | Steady import schedules with buffer stock |

| Technical Support | Helps optimize product formulation | In-house experts and application testing |

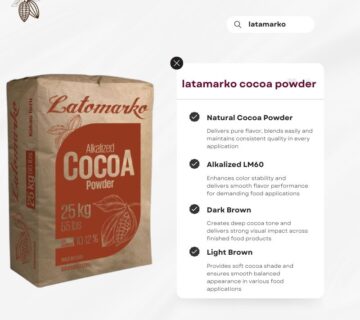

Spanish manufacturers like Latamarko have set benchmarks in this regard. Their precision-engineered cocoa powders deliver consistent color and taste profiles, making them ideal for Turkish chocolate and beverage applications that demand uniformity across large production batches.

Common Misconceptions About Cocoa Powder Procurement

Many new procurement officers assume that all cocoa powders are interchangeable. In reality, small variations in pH or fat composition can drastically affect viscosity, aroma, and even the stability of emulsions in industrial mixtures. Another misconception is that imported cocoa powders automatically imply higher cost — but this isn’t always true. Strategic import partnerships often yield better cost-per-unit outcomes due to superior yield efficiency and reduced waste during mixing or molding.

We’ve seen factory managers cut costs not by switching to cheaper alternatives, but by improving consistency through better supplier relationships. Stable quality reduces rework, energy consumption, and flavor adjustment efforts — savings that accumulate significantly in large-scale operations.

How Cocoa Powder Imports Fuel Türkiye’s Manufacturing Growth

Türkiye’s confectionery exports have surged in recent years, driven by increasing global demand for Turkish chocolate, biscuits, and drink mixes. Cocoa powder imports enable manufacturers to maintain competitiveness by offering stable sensory profiles and extended shelf life — factors essential for export compliance.

Beyond confectionery, imported cocoa powder also supports Türkiye’s growing nutraceutical and instant beverage sectors. Low-fat cocoa varieties are now used in protein shakes, meal replacements, and functional foods that target health-conscious consumers worldwide. Importers who can supply food-grade cocoa powders with clean labeling and traceable origins help manufacturers tap into these lucrative market segments.

Industrial Applications: Choosing the Right Cocoa Powder for the Job

Each production environment demands a unique cocoa powder specification. For instance:

- Chocolate Manufacturing – Requires high-fat cocoa (20–22%) for rich texture and smooth mouthfeel.

- Bakery Applications – Favor low-fat cocoa (10–12%) for better aeration and reduced oil separation.

- Beverage Industry – Prefers alkalized cocoa for improved solubility and consistent color in liquid formulations.

- Dessert Premixes – Depend on controlled particle size to ensure uniform flavor dispersion.

Premium options from European suppliers — particularly those with Spanish engineering like Latamarko — are prized for their process stability and neutral flavor tones, which make them adaptable to different product bases.

The MT Royal Advantage in Cocoa Powder Importation

At MT Royal, we supply manufacturers with a comprehensive range of cocoa powder brands — from cost-effective industrial blends to premium European selections. Our expertise extends beyond distribution; we help factories select the right grade based on fat content, alkalization level, and intended application.

We’ve observed firsthand that when procurement teams prioritize quality consistency over short-term pricing, they experience fewer production halts, better color uniformity, and higher customer satisfaction. Our partnerships span major confectionery producers, bakeries, and beverage factories throughout Türkiye — all benefiting from stable supply chains and transparent sourcing.

Avoiding Procurement Pitfalls: Lessons from the Factory Floor

Even experienced production managers sometimes fall into procurement traps. Common issues include:

- Over-reliance on a single supplier, which can expose factories to logistics disruptions.

- Ignoring particle size distribution, leading to poor solubility in beverage mixes.

- Selecting by price rather than yield, which affects cost-per-unit more than purchase cost.

- Neglecting storage conditions, allowing moisture absorption and flavor loss.

To mitigate these risks, procurement teams should request detailed technical data sheets (TDS) and quality certificates before placing large orders. Importers like MT Royal ensure that every shipment comes with full traceability documentation and post-delivery support.

Key Considerations for Bulk Buyers and Factory Managers

Industrial cocoa procurement is as much about logistics as it is about taste. Here are several considerations that successful Turkish factories consistently apply:

- Batch Consistency – Always check the variance between batches; it should remain within 1–2% for color and flavor.

- Shelf Stability – Imported cocoa powders with lower moisture content perform better in hot, humid climates.

- Mixing Efficiency – Proper granulation minimizes clumping during automated feeding.

- Fat Bloom Control – High-quality cocoa prevents undesirable whitening in finished chocolate products.

- Sustainability Credentials – Increasingly, buyers prefer importers who work with ethical and traceable sources.

Trends Shaping Cocoa Powder Importation in Türkiye

The landscape of cocoa powder importation is evolving. Türkiye’s industrial buyers are demanding greater traceability, cleaner labeling, and more adaptable formulations for diverse markets. Sustainability certifications, such as Rainforest Alliance and UTZ, are becoming prerequisites rather than optional extras.

Moreover, European-origin powders are gaining traction as Turkish factories target high-end export markets. Spanish suppliers like Latamarko are recognized for their precise alkalization techniques and smooth flavor profiles, aligning with premium Turkish brands seeking to differentiate themselves on quality rather than price.

Meanwhile, domestic importers are expanding technical support capabilities — helping factories with pilot testing, color calibration, and viscosity optimization. This value-added approach positions Türkiye as not only a major cocoa consumer but a regional processing hub connecting Europe, the Middle East, and North Africa.

Frequently Asked Questions (FAQ)

Q1: Why does Türkiye rely heavily on imported cocoa powder?

Because cocoa is not cultivated domestically at commercial scale, Turkish manufacturers import to ensure consistent quality and volume.

Q2: Which countries are the leading sources for Türkiye’s cocoa powder imports?

The Netherlands, Spain, Indonesia, and Malaysia remain dominant exporters due to their advanced processing and quality control systems.

Q3: What certifications should industrial buyers request from importers?

ISO 22000, HACCP, Halal, and Kosher certifications are standard. Sustainability labels like UTZ or Fairtrade are increasingly valued.

Q4: How can importers support product innovation?

By offering customized blends and technical consultations tailored to specific production environments.

Q5: Are European cocoa powders better for premium chocolate?

Generally yes, as they deliver consistent color, smoother texture, and better flavor retention — attributes associated with brands like Latamarko.

Strategic Insight: Building a Resilient Cocoa Supply Framework

For Türkiye’s industrial sector, securing a dependable cocoa powder importer is not just procurement — it’s strategy. The right partner ensures uninterrupted production, predictable costs, and the ability to scale with market trends. As factories modernize and export volumes grow, collaboration between manufacturers and specialized importers like MT Royal will define the next era of confectionery and beverage excellence.

Reliable sourcing, consistent performance, and transparent partnerships form the foundation of every successful chocolate operation. As Türkiye continues to strengthen its position as a global manufacturing hub, one question remains at the heart of every production meeting: Who will you trust to keep your cocoa supply as consistent as your quality standards?

No comment