Cocoa powder is produced through a series of processes involving the extraction of cocoa beans and the subsequent processing of the extracted material. The detailed steps include:

Harvesting Cocoa Pods: Cocoa powder starts with the harvesting of cocoa pods. Cocoa trees produce large pods that contain cocoa beans. These pods are typically harvested manually using machetes or other tools.

Harvesting cocoa pods is a crucial step in the production of cocoa powder and chocolate. Here is an overview of the process:

- Cocoa Tree Cultivation: Cocoa trees (Theobroma cacao) are primarily grown in tropical regions near the equator, including West Africa, South America, and Southeast Asia. These trees require specific conditions, including warm temperatures, high humidity, and well-distributed rainfall.

- Tree Maturity: Cocoa trees typically start producing pods when they reach three to five years of age. However, the optimal yield is achieved when the trees are around five to ten years old.

- Flowering: Cocoa trees produce small, inconspicuous flowers directly on the trunk and branches. These flowers contain both male and female parts. Successful pollination is necessary for the development of cocoa pods.

- Pollination: Cocoa trees are primarily pollinated by tiny insects like midges. The pollination process is essential for the formation of cocoa pods. However, in some cocoa plantations, human-assisted pollination may be carried out to ensure a higher yield.

- Cocoa Pod Development: After successful pollination, the flowers develop into large, elongated pods. The pods typically take five to six months to mature. The size, shape, and color of the pods can vary depending on the cocoa variety.

- Harvesting: Harvesting cocoa pods is usually done manually, and the timing is crucial. Harvesters use machetes or other tools to carefully cut the pods from the tree without damaging the delicate buds or branches. The pods are often harvested when they have turned a mature color (yellow or red, depending on the variety) and are slightly soft to the touch.

- Frequency of Harvesting: Cocoa trees can produce pods throughout the year, and the frequency of harvesting depends on the specific cocoa variety and the local climate. In some regions, there may be two main harvesting seasons, while in others, cocoa pods can be harvested year-round.

- Post-Harvest Handling: After harvesting, the cocoa pods are collected in baskets or sacks. The next steps involve opening the pods to extract the cocoa beans and preparing them for the fermentation process. The outer husk of the pod is typically discarded or used for other purposes.

Cocoa harvesting is labor-intensive, and it often involves the work of local farmers or laborers who have experience in identifying ripe pods and using the necessary tools for harvesting. Sustainable and ethical harvesting practices are essential to ensure the well-being of the farmers and the quality of the cocoa beans produced.

Removing Cocoa Beans from Pods: Once harvested, the cocoa pods are opened, and the beans are removed. The beans are embedded in a sweet pulp, which is usually discarded or used for other purposes.

After cocoa pods are harvested, the next step in the cocoa production process is removing the cocoa beans from the pods. This process involves several steps to extract the valuable beans from the pods while separating them from the surrounding pulp. Here is an overview of how cocoa beans are removed from pods:

- Opening the Cocoa Pods: The harvested cocoa pods have a tough outer rind. To extract the beans, the pods need to be opened. This is typically done manually, using machetes or other sharp tools. The goal is to crack open the pod without damaging the beans inside.

- Pulp and Bean Removal: Once the pod is open, the cocoa beans are found embedded in a sweet, mucilaginous pulp. The beans are attached to the inner walls of the pod. Workers carefully remove the beans from the pulp, ensuring not to damage the beans or leave any pulp attached.

- Fermentation Troughs or Bins: The extracted beans, along with the surrounding pulp, are usually collected in containers like troughs or bins. These containers may be made of wood, banana leaves, or other locally available materials.

- Fermentation of Cocoa Beans: After the beans are removed from the pods, they are placed in the containers to undergo a fermentation process. Fermentation is a crucial step in the development of cocoa flavor. During this stage, the pulp surrounding the beans liquifies and drains away, leaving the beans to undergo chemical changes that contribute to the characteristic taste of cocoa.

- Turning and Mixing: During fermentation, it is common to turn or mix the beans to ensure even fermentation. This process helps in achieving uniform flavor development and prevents uneven fermentation or the growth of mold.

- Duration of Fermentation: The duration of fermentation can vary depending on factors such as the specific cocoa variety and local practices. It typically takes several days for the fermentation process to be completed.

- Drying the Fermented Beans: After fermentation, the beans are spread out to dry. This can be done by laying them in the sun on trays, mats, or elevated drying beds. Proper drying is essential to reduce moisture content and prepare the beans for the subsequent stages of processing.

The process of removing cocoa beans from pods is a critical phase that sets the foundation for the flavor and quality of the final cocoa product. It requires careful handling to ensure that the beans are not damaged and to facilitate the subsequent steps in the cocoa production process.

Fermentation: The freshly extracted cocoa beans are then placed in containers and left to ferment. Fermentation is a crucial step in developing the flavor of the cocoa. During this process, the pulp surrounding the beans transforms into liquid and drains away, while the beans undergo chemical changes that contribute to the development of cocoa flavor.

Fermentation is a crucial step in the production of cocoa beans, playing a significant role in developing the flavor and characteristics of the final cocoa and chocolate products. Here’s an in-depth look at the fermentation process:

- Harvesting and Opening Pods: The fermentation process begins after the cocoa pods are harvested and the cocoa beans are removed from the pods. The beans are typically covered in a sweet, mucilaginous pulp.

- Filling Fermentation Bins or Boxes: The extracted beans, along with the pulp, are placed in containers such as wooden bins, boxes, or heaps. These containers allow for air circulation and the drainage of liquids during fermentation.

- Microbial Action: Natural microorganisms, including yeasts and bacteria, present on the surface of the beans and in the environment, initiate the fermentation process. These microorganisms consume the sugars present in the pulp, producing byproducts such as alcohol and acids.

- Temperature and Aeration: Fermentation generates heat as a byproduct, and the temperature inside the fermentation mass rises. The heat is essential for enzymatic reactions that contribute to flavor development. Additionally, the heat helps to kill the cocoa germ within the bean. Aeration is crucial to prevent the growth of undesirable microorganisms and ensure even fermentation.

- Color Changes: The beans undergo color changes during fermentation. Initially, they are purple or violet, but they gradually turn brown as fermentation progresses.

- Duration of Fermentation: The duration of fermentation varies based on factors such as cocoa variety, local practices, and environmental conditions. Fermentation typically takes several days, with the exact duration depending on the desired flavor profile.

- Turning and Mixing: Periodic turning or mixing of the beans during fermentation is common. This helps distribute heat, ensure uniform fermentation, and prevent the formation of mold. It is a hands-on process often performed by skilled workers.

- Evaluation of Fermentation: Experienced cocoa farmers or processors often evaluate the progress of fermentation by observing the aroma, color, and texture of the beans. Properly fermented beans should have a characteristic chocolate aroma.

- Termination of Fermentation: Once fermentation is complete, the beans are considered “fully fermented.” At this point, they are removed from the fermentation bins and proceed to the next stage of processing.

Fermentation is a critical step that contributes to the development of the complex flavor compounds found in cocoa. It transforms the raw, astringent taste of the beans into the desirable chocolate flavor. The success of the fermentation process is key to producing high-quality cocoa that will be used in the production of chocolate products.

Drying: After fermentation, the beans are spread out to dry. This can be done under the sun or using specialized drying equipment. Proper drying is essential to prevent mold growth and to prepare the beans for further processing.

Drying is a crucial step in the cocoa processing journey, transforming fermented and wet cocoa beans into the dry cocoa beans that can be further processed into cocoa products, including cocoa powder and chocolate. Here’s an overview of the drying process in cocoa production:

- Fermentation:

- Before drying, cocoa beans undergo a fermentation process. This step is vital for developing the characteristic chocolate flavor. The beans are placed in heaps or containers, and microbial activity begins, producing heat and initiating biochemical changes.

- Harvesting and Collection:

- After fermentation, the beans are removed from the fermentation containers and spread out to dry. The beans are typically spread on mats, trays, or drying platforms to ensure even drying.

- Drying Methods:

- There are different methods of drying cocoa beans, and the choice of method can impact the flavor and quality of the final cocoa product. Common drying methods include:

- Sun Drying: Beans are spread out in the sun and turned regularly to ensure even drying.

- Mechanical Drying: In some cases, mechanical dryers are used, especially in large-scale production. These dryers use controlled temperature and airflow to dry the beans.

- There are different methods of drying cocoa beans, and the choice of method can impact the flavor and quality of the final cocoa product. Common drying methods include:

- Duration of Drying:

- Drying can take several days, and the duration depends on factors such as weather conditions, the drying method used, and the desired moisture content of the beans. The goal is to reduce the moisture content to a level suitable for storage and further processing.

- Moisture Content:

- Properly dried cocoa beans should have a moisture content of around 6-7%. This low moisture content is crucial for preventing mold growth during storage and transportation.

- Quality Control:

- Throughout the drying process, quality control measures are implemented to ensure that the beans meet the required standards. This includes visual inspections, monitoring moisture levels, and addressing any issues that may arise during drying.

- Storage:

- Once the cocoa beans are dried and have reached the desired moisture content, they are typically stored in a cool, dry place until they are ready for further processing. Proper storage conditions are essential to maintain the quality of the beans.

Drying is a critical stage in the production of cocoa, as it not only prepares the beans for storage and transportation but also plays a role in shaping the flavor profile of the final cocoa product. The careful execution of the drying process contributes to the development of the characteristic chocolate taste that consumers associate with high-quality cocoa products.

Roasting: The dried cocoa beans are roasted to enhance the flavor. Roasting also helps to remove any remaining moisture and to develop the characteristic cocoa aroma. The temperature and duration of roasting play a significant role in determining the final flavor profile of the cocoa.

Roasting is a crucial step in the processing of cocoa beans, playing a pivotal role in developing the rich and complex flavors associated with chocolate. The roasting process transforms fermented and dried cocoa beans into the familiar cocoa aroma and taste. Here’s an overview of the roasting process in cocoa production:

- Preparation:

- Before roasting, dried cocoa beans are thoroughly cleaned and sorted. Any extraneous material is removed to ensure the purity of the final product.

- Heating:

- The cleaned cocoa beans are then subjected to heat in a roasting chamber or rotating drum. The roasting temperature and duration are critical factors that influence the flavor, color, and aroma of the final cocoa product.

- Roasting Parameters:

- Temperature: Roasting temperatures typically range from 250°F to 350°F (120°C to 175°C). Higher temperatures generally result in a bolder, more intense flavor.

- Time: The duration of roasting can vary but generally falls within the range of 20 to 60 minutes. Longer roasting times at lower temperatures may produce different flavor profiles than shorter times at higher temperatures.

- Maillard Reaction:

- The Maillard reaction is a complex chemical process that occurs during roasting. It involves the interaction of amino acids and reducing sugars, leading to the development of brown color, characteristic aromas, and a complex flavor profile.

- Acid Reduction:

- Roasting also contributes to the reduction of acidity in the beans. The initial acidity from the fermentation process is mellowed during roasting, resulting in a smoother and more palatable flavor.

- Aroma Development:

- The roasting process is crucial for developing the aromatic compounds that contribute to the characteristic chocolate scent. These aromas are a key component of the overall chocolate experience.

- Cooling:

- After roasting, the beans are rapidly cooled to halt the cooking process and stabilize the roasted flavors. This can be done using air or water cooling methods.

- Quality Control:

- Quality control measures are implemented throughout the roasting process. Sampling and sensory evaluations help ensure that the beans meet the desired flavor profile and quality standards.

The careful control of roasting parameters, including temperature, time, and cooling, allows chocolate manufacturers to achieve specific flavor profiles. Different roast profiles can result in chocolates with varied notes, ranging from fruity and floral to deep and nutty.

The art of roasting lies in balancing the desire for robust flavor development with the need to preserve the nuanced characteristics of the cocoa beans. The expertise of the chocolate maker, combined with precise control of roasting conditions, contributes significantly to the final taste and quality of the chocolate.

Winnowing: The roasted beans are then cracked open, and the outer shell (husk) is removed through a process called winnowing. This leaves behind the cocoa nibs, which are the pure cocoa solids.

Winnowing is a crucial step in the post-harvest processing of cocoa beans and is performed after the beans have been roasted. This process involves the separation of the outer shell (husk or shell) from the inner part of the cocoa bean, known as the nib. Winnowing is a key stage in the production of cocoa nibs, which are the primary ingredient for making chocolate. Here’s an overview of the winnowing process:

- Roasted Cocoa Beans:

- After roasting, the cocoa beans undergo a process called cracking, where the outer shell is fractured, exposing the cocoa nibs inside.

- Cracking:

- The roasted cocoa beans are mechanically cracked to break open the shells and release the nibs. The cracking process can be achieved through various methods, including milling and impact methods.

- Winnowing Machine:

- The cracked cocoa beans, which now contain a mixture of nibs and shell fragments, are then subjected to winnowing. The winnowing machine uses airflow to separate the lighter shell fragments from the heavier cocoa nibs.

- Airflow Separation:

- The winnowing machine typically uses a combination of controlled air currents and gravity. The cracked cocoa beans are dropped or conveyed into the winnowing chamber, where a stream of air is directed through the mixture.

- Gravity Assistance:

- As the air flows through the winnowing chamber, the lighter shell fragments are carried away by the airflow, while the heavier cocoa nibs fall due to gravity. This separation is facilitated by the difference in weight between the nibs and the shells.

- Collection Bins:

- The separated cocoa nibs and shell fragments are directed into separate collection bins. The collected nibs are then ready for further processing to produce cocoa mass, cocoa powder, or chocolate.

- Cleaning and Grading:

- After winnowing, the cocoa nibs may undergo additional cleaning and grading processes to remove any remaining shell fragments and ensure the quality of the final product.

- Reuse of Shells:

- The separated shell fragments, known as cocoa husks or shells, are not wasted. They can be repurposed for various applications, such as fertilizer, animal feed, or even as a source of bioenergy.

Winnowing is a critical step in cocoa processing as it helps to separate the desirable cocoa nibs from the less flavorful and more fibrous outer shell. The efficiency of winnowing contributes to the overall quality of the cocoa products that follow in the chocolate-making process.

Grinding: The cocoa nibs are ground into a thick paste known as chocolate liquor. This paste contains both cocoa solids and cocoa butter. The grinding process generates heat, which liquefies the cocoa butter, resulting in a smooth, liquid consistency.

Grinding is a fundamental step in the processing of cocoa beans, where the roasted beans are ground into a paste or liquid known as cocoa mass or cocoa liquor. This cocoa mass serves as a key ingredient in the production of various chocolate products. Here’s an overview of the grinding process in cocoa production:

- Preparation:

- After roasting and winnowing, the cocoa nibs are collected and ready for grinding. The nibs contain both cocoa solids and cocoa butter.

- Grinding Equipment:

- The cocoa nibs are ground using specialized grinding equipment. Traditionally, stone mills were used, but modern processing facilities often use grinding machines such as ball mills, roller mills, or specially designed grinding equipment for cocoa processing.

- Grinding Process:

- The grinding process involves applying mechanical forces to the cocoa nibs, breaking them down into smaller particles. The grinding equipment typically consists of grinding stones or other grinding surfaces that crush and refine the nibs.

- Temperature Control:

- Temperature control is crucial during the grinding process to prevent the cocoa mass from overheating. Excessive heat can lead to the separation of cocoa butter from the cocoa solids, affecting the texture and quality of the final product.

- Cocoa Mass Formation:

- As the grinding progresses, the cocoa nibs release cocoa butter, forming a thick and viscous liquid known as cocoa mass or cocoa liquor. This cocoa mass contains both finely ground cocoa solids and cocoa butter.

- Particle Size Reduction:

- The grinding process aims to achieve a specific particle size distribution in the cocoa mass. The desired particle size can vary depending on the type of chocolate being produced and the specific requirements of the chocolate manufacturer.

- Quality Control:

- Quality control measures, such as regular sampling and testing, are implemented during grinding to ensure that the cocoa mass meets the desired specifications for flavor, texture, and particle size.

- Further Processing:

- The cocoa mass produced through grinding can be further processed to separate cocoa solids from cocoa butter. This separation can result in the production of cocoa powder and cocoa butter, both essential ingredients in chocolate manufacturing.

- Conching (Optional):

- In some chocolate production processes, the cocoa mass undergoes a conching step. Conching involves further refining the chocolate by subjecting it to mechanical agitation and controlled heat. This step contributes to the smoothness and texture of the final chocolate product.

- Storage:

- The final cocoa mass, cocoa powder, or other chocolate ingredients are then stored in suitable conditions until they are ready to be used in the production of chocolate products.

Grinding is a critical step in chocolate manufacturing, influencing the flavor, texture, and overall quality of the final chocolate product. The precision and control exercised during grinding contribute significantly to the characteristics of the chocolate consumers enjoy.

Pressing: The chocolate liquor undergoes pressing to separate the cocoa solids from the cocoa butter. The extracted cocoa solids are further processed to produce cocoa powder.

Pressing is a step in the cocoa processing that involves separating cocoa solids from cocoa butter. This separation is crucial for obtaining different components that can be used in various chocolate products. Here’s an overview of the pressing process:

- Cocoa Mass:

- After the grinding process, cocoa nibs are transformed into a thick and viscous liquid known as cocoa mass or cocoa liquor. This cocoa mass contains both finely ground cocoa solids and cocoa butter.

- Pressing Equipment:

- The pressing process involves the use of hydraulic presses or screw presses. These presses apply pressure to the cocoa mass, separating the cocoa solids from the cocoa butter.

- Separation of Cocoa Butter:

- The cocoa mass is subjected to high pressure, causing the cocoa butter to separate from the cocoa solids. Cocoa butter is a fat, and under pressure, it is forced out of the cocoa mass, leaving behind a cake of compressed cocoa solids.

- Cocoa Solids Cake:

- The cake of compressed cocoa solids is then removed from the press. This cake is relatively dry and can be further processed to produce cocoa powder or used as an ingredient in various chocolate products.

- Cocoa Butter Collection:

- The expelled cocoa butter is collected and can be used in the production of chocolate or other applications. Cocoa butter is a crucial ingredient in chocolate, contributing to its smooth texture and mouthfeel.

- Quality Control:

- Quality control measures are implemented during pressing to ensure that the separation of cocoa solids and cocoa butter meets the desired specifications. This includes monitoring the pressure applied, the temperature, and the quality of the final products.

- Further Processing (Optional):

- Depending on the desired end products, the cocoa solids and cocoa butter may undergo additional processing steps. For example, the cocoa solids may be further refined into cocoa powder through processes such as milling and classification.

- Storage:

- The separated cocoa solids and cocoa butter are stored in appropriate conditions until they are ready to be used in the production of chocolate products.

Pressing is a critical step in the cocoa processing chain as it allows for the separation of cocoa butter and cocoa solids, providing the raw materials for a variety of chocolate products with different formulations and characteristics. The efficiency and precision of the pressing process contribute significantly to the quality of the final chocolate products.

Dutch Process (Optional): In some cases, cocoa powder may undergo Dutch processing, where it is treated with an alkalizing agent to modify its color and reduce acidity. This results in Dutch-processed or alkalized cocoa powder, which is often darker and has a milder flavor.

Dutch processing, also known as alkalization or Dutching, is an optional step in cocoa processing that involves treating cocoa powder with an alkaline solution, typically potassium carbonate. This process was developed by the Dutch chocolate maker Conrad Van Houten in the 19th century and is used to modify the color, flavor, and solubility of cocoa powder. Here’s an overview of the Dutch process:

- Treatment with Alkali:

- In Dutch processing, cocoa powder is treated with an alkaline solution, usually potassium carbonate. This treatment alters the pH of the cocoa, reducing its natural acidity.

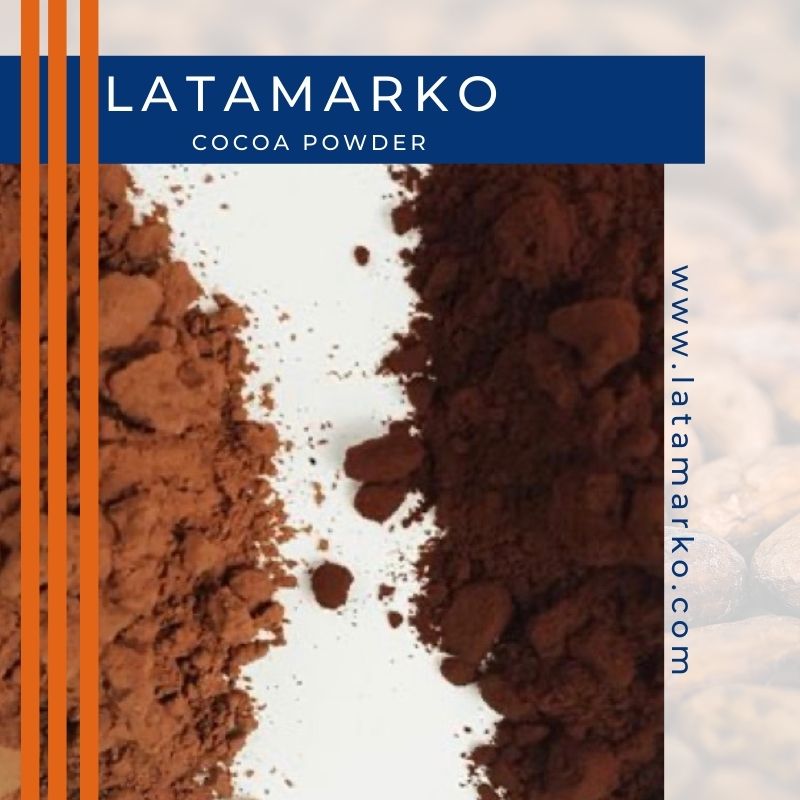

- Color Modification:

- One of the primary effects of Dutch processing is a change in the color of cocoa powder. Untreated, or natural, cocoa powder has a lighter color, while Dutch-processed cocoa powder is darker, often with a reddish-brown hue.

- Flavor Modification:

- Dutch processing results in a milder and less astringent flavor compared to untreated cocoa powder. The alkalization process can also contribute to a smoother and more rounded taste.

- Solubility Improvement:

- Dutch-processed cocoa powder tends to have improved solubility in liquids compared to untreated cocoa powder. This makes it easier to incorporate into recipes and beverages.

- Applications:

- Dutch-processed cocoa powder is often preferred in recipes that require a milder flavor and darker color. It is commonly used in European-style baking, confectionery, and beverages.

- Baking Powder vs. Baking Soda Recipes:

- Dutch-processed cocoa powder is suitable for recipes that use baking powder as the leavening agent. Its reduced acidity complements the alkaline nature of baking powder. In contrast, natural cocoa powder is often used in recipes that rely on baking soda.

- Availability:

- Dutch-processed cocoa powder is widely available and is labeled as “Dutch-processed” or “alkalized” on packaging. Natural cocoa powder is labeled simply as “cocoa” or “natural cocoa.”

It’s important to note that the choice between Dutch-processed and natural cocoa powder depends on the specific requirements of a recipe. While Dutch-processed cocoa powder offers certain advantages, such as a milder flavor and darker color, it may not be suitable for recipes that specifically call for the acidity of natural cocoa powder to interact with baking soda for leavening.

Chocolate enthusiasts and bakers often choose between Dutch-processed and natural cocoa powder based on their preferences and the desired characteristics for a particular recipe. Both types have their places in the culinary world, and the choice depends on the specific application and desired outcomes.

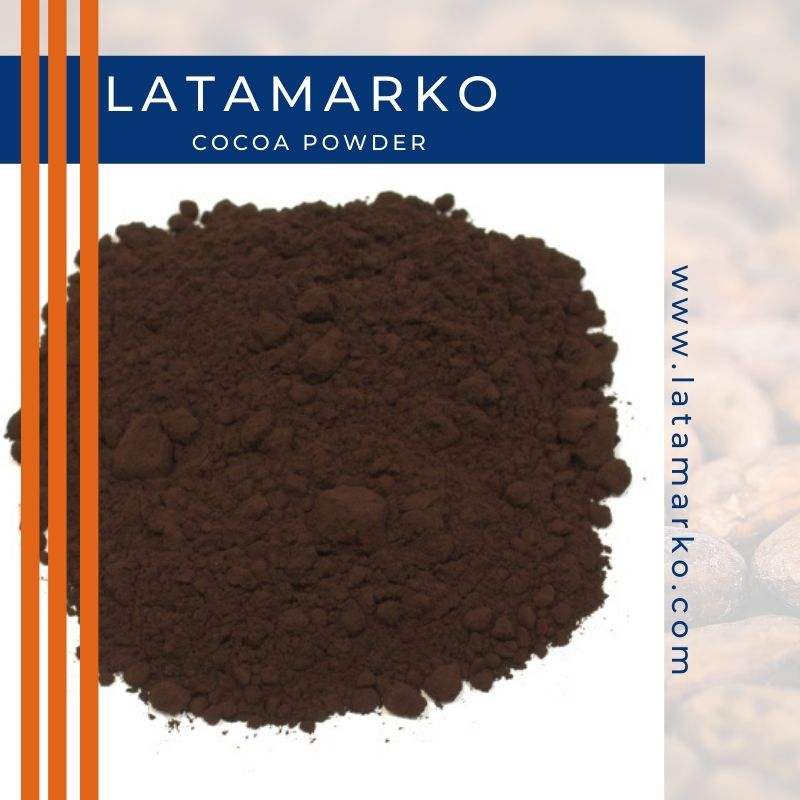

Types of Cocoa Powder:

- Natural Cocoa Powder:

- Produced by pressing chocolate liquor without additional processing.

- Retains a light brown color and has a more acidic and fruity flavor.

- Dutch-Processed (Alkalized) Cocoa Powder:

- Treated with alkaline substances to neutralize acidity.

- Often darker in color with a milder flavor.

- Dissolves more easily in liquids.

Cocoa powder produced through these processes is then used in various culinary applications, including baking, beverage preparation, and chocolate production.

No comment