When your production line depends on consistent throughput, predictable wear behavior, and mechanical stability under pressure, selecting the right cone crusher is not a routine procurement task—it is a long-term operational decision. This is exactly why searches for a Cone Crusher 440 manufacturer in Ukraine are becoming more targeted and more frequent among quarry owners, mining companies, and industrial producers who refuse to gamble with downtime.

From the first interaction, MT Royal approaches this requirement with a different mindset. Instead of presenting machinery as isolated products, we focus on how Cone Crusher 440 units behave over years of operation, across varying rock types and load conditions. We have seen how Ukrainian-manufactured cone crushers, when sourced with technical discipline and realistic expectations, deliver a level of mechanical honesty that many buyers only recognize after they have experienced costly alternatives.

This article is written to fully answer the real search intent behind Cone Crusher 440 manufacturer in Ukraine. It is not a catalog summary. It is a practical, experience-driven guide designed for decision-makers who value performance, durability, and clarity over short-term savings.

Understanding the Cone Crusher 440 and its role in crushing circuits

A Cone Crusher 440 typically occupies a critical position in secondary or tertiary crushing stages. While jaw crushers handle raw feed and impact crushers focus on shaping, the cone crusher determines consistency. It is the machine that quietly defines whether your plant runs smoothly or constantly fights bottlenecks.

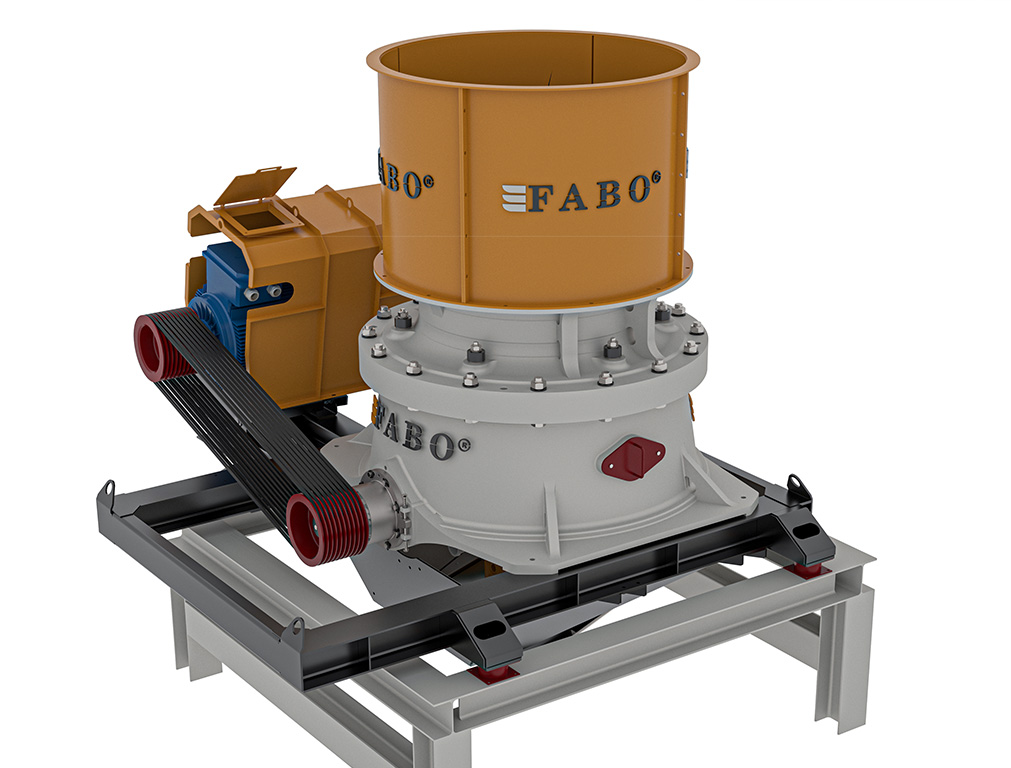

At a mechanical level, the Cone Crusher 440 works by compressing material between a rotating mantle and a fixed concave liner. What matters is not the concept, but how effectively the machine controls:

- Crushing force distribution

- Particle size reduction

- Wear progression

- Vibration and thermal stability

Ukrainian manufacturers have long designed cone crushers for mining environments where failure is not tolerated. This heritage strongly influences the design philosophy behind Cone Crusher 440 units produced in Ukraine today.

Why Ukraine stands out in cone crusher manufacturing

Ukraine’s heavy machinery sector is built on decades of industrial production for mining, metallurgy, and energy infrastructure. This background is not theoretical—it shapes how machines are designed, tested, and refined.

Several factors explain why a Cone Crusher 440 manufacturer in Ukraine attracts serious industrial buyers:

Engineering-first design culture

Ukrainian manufacturers tend to prioritize structural strength, shaft stability, and bearing life over cosmetic refinement. These are machines built to work, not to impress in showrooms.

Integrated manufacturing processes

Many factories control casting, heat treatment, machining, and assembly internally. This reduces tolerance inconsistencies and improves mechanical alignment.

Experience with abrasive and hard materials

Cone crushers originally developed for iron ore, granite, and basalt mining translate naturally to aggregate and quarry operations.

Competitive cost structure

While maintaining solid engineering standards, Ukrainian manufacturers benefit from production costs that remain lower than Western Europe, allowing better value propositions.

For buyers who calculate cost per ton rather than purchase price, this combination is difficult to ignore.

Typical applications of Cone Crusher 440 units

The Cone Crusher 440 is selected for applications where output quality and operational stability matter more than sheer speed.

Common use cases include:

- Quarry operations producing aggregates for infrastructure and concrete

- Mining operations processing medium-to-hard ores

- Recycling plants handling concrete, slag, and industrial byproducts

- Industrial mineral processing facilities

In many plants, the cone crusher becomes the reference point for downstream equipment performance. When it runs smoothly, everything else follows. When it struggles, the entire line feels it.

What defines a reliable Cone Crusher 440 manufacturer in Ukraine

Not every manufacturer operating in Ukraine delivers the same level of reliability. Identifying the right partner requires attention to technical detail rather than marketing language.

Frame and main shaft design

High-quality manufacturers design frames and shafts to resist deformation under continuous load. This directly affects bearing life and vibration levels.

Wear part metallurgy

Mantles and concaves are not interchangeable commodities. Alloy composition and heat treatment determine wear resistance and breakage behavior.

Lubrication and sealing systems

Dust contamination is one of the fastest ways to destroy a cone crusher. Effective sealing and oil circulation systems significantly extend service intervals.

Documentation and export readiness

Clear technical manuals, spare part drawings, and maintenance schedules are signs of a manufacturer prepared for international clients.

At MT Royal, we evaluate these elements carefully before recommending any Cone Crusher 440 supplier.

Common sourcing mistakes in cone crusher procurement

Even experienced buyers can fall into predictable traps.

Assuming model numbers guarantee equivalence

Two Cone Crusher 440 machines from different manufacturers can differ dramatically in capacity, liner geometry, and durability.

Underestimating wear costs

Low initial pricing often hides expensive wear part replacement cycles.

Ignoring plant-specific conditions

Feed variability, moisture, temperature, and dust levels must influence design choices.

We have seen production lines suffer not because the crusher was fundamentally bad, but because it was mismatched to the operating environment.

Comparing Ukrainian Cone Crusher 440 units with other regions

Versus Western European manufacturers

Western European crushers offer refined engineering but often come with higher acquisition and maintenance costs. Ukrainian units frequently deliver comparable mechanical strength at a more accessible price.

Versus Asian manufacturers

Some Asian suppliers compete aggressively on price but may struggle with consistent metallurgy and long-term wear performance.

Versus legacy equipment

Modern Ukrainian manufacturers have moved far beyond outdated designs, integrating CNC machining, improved alloys, and better sealing systems.

This positioning makes Cone Crusher 440 manufacturer in Ukraine a rational option rather than a compromise.

Industrial considerations for high-capacity crushing plants

Large-scale operations introduce additional complexity.

Throughput stability

A cone crusher that handles variable feed without surging reduces stress on screens and conveyors.

Maintenance accessibility

Designs that allow faster liner changes and easier inspections reduce downtime.

Energy efficiency

Stable crushing action and optimized geometry reduce unnecessary power consumption.

We have observed that plants focusing on these factors achieve lower total cost of ownership over time.

The MT Royal approach to sourcing Cone Crusher 440 units

Sourcing from Ukraine is not simply about choosing a factory. It requires verification, technical alignment, and logistics planning.

MT Royal works as a sourcing partner rather than a catalog reseller. We collaborate with multiple manufacturers, selecting partners based on proven performance, export readiness, and engineering depth.

We have seen that structured sourcing—factory audits, specification alignment, and spare parts planning—turns international procurement into a controlled, predictable process. This is where trust is built through results, not promises.

Frequently asked questions from plant managers and buyers

Is a Ukrainian Cone Crusher 440 suitable for hard rock applications?

Yes. Many are designed specifically for high-abrasion environments.

How reliable is spare parts availability?

With the right supplier structure, spare parts can be planned and stocked predictably.

Can these crushers be customized?

Most Ukrainian manufacturers offer customization in liner profiles, drive systems, and configurations.

What about compliance and safety standards?

Modern units can be specified to align with international industrial safety expectations.

Long-term operational impact of the right cone crusher choice

A cone crusher rarely fails dramatically on day one. Its true quality reveals itself gradually—in wear rates, vibration patterns, and maintenance intervals.

Choosing the right Cone Crusher 440 manufacturer in Ukraine is not about chasing novelty or branding. It is about investing in mechanical consistency and operational predictability.

At MT Royal, we believe that strong production lines are built on informed decisions. When engineering discipline, sourcing strategy, and real-world operating conditions align, factories gain more than equipment—they gain confidence in their output and control over their future capacity.

In heavy industry, trust is earned quietly, ton by ton. The right cone crusher proves itself not through promises, but through years of uninterrupted work.

No comment