In Türkiye’s rapidly advancing food manufacturing ecosystem, high fat cocoa powder has evolved from being a simple flavoring component into a core functional ingredient that defines the sensory and technical quality of finished goods. As Türkiye strengthens its position as a regional hub for chocolate, bakery, and confectionery exports, the demand for premium-grade cocoa ingredients—particularly those with higher fat content—has grown exponentially.

Unlike ordinary cocoa powders that mainly contribute color and aroma, high fat cocoa powder significantly impacts the structure, texture, and overall performance of chocolate-based formulations. It influences how chocolate melts in the mouth, how fillings maintain stability under fluctuating temperatures, and even how easily a coating flows through enrobing machines. In large-scale industrial setups, such as automated chocolate lines or continuous mixers, these differences can determine whether production runs smoothly or faces costly interruptions.

Across Türkiye’s leading production zones—Istanbul, Bursa, Izmir, and Gaziantep—factory managers and procurement teams are becoming increasingly aware that not all cocoa powders are created equal. Small variations in fat content, particle size, or moisture level can drastically affect mixing behavior, viscosity, and color uniformity. For example, a chocolate glaze intended for export markets requires a precise fat ratio to maintain gloss and stability across long transit conditions. Similarly, bakery manufacturers rely on high fat cocoa to achieve deeper coloration and a more indulgent flavor profile that appeals to both domestic and international consumers.

Moreover, the global shift toward premiumization and natural formulations has encouraged Turkish manufacturers to move away from synthetic enhancers and low-fat substitutes. Instead, they now emphasize using authentic high fat cocoa powder to achieve richer taste, longer shelf stability, and better consumer perception. This transition underscores the importance of choosing the right high fat cocoa powder supplier in Türkiye—one capable of ensuring consistent quality, technical support, and reliable bulk delivery.

From a procurement standpoint, supplier selection is no longer just about price competitiveness. It is a strategic decision that affects every stage of production, from mixing ratios to energy consumption. An inferior batch of cocoa powder can disrupt machine calibration, increase waste, and damage brand reputation due to product inconsistency. Conversely, partnering with a reputable supplier—one that understands industrial needs and provides technical documentation—can streamline processes, reduce downtime, and maintain a stable cost-per-unit ratio.

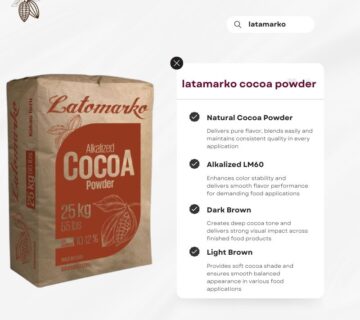

In this context, MT Royal has become a trusted name among Turkish manufacturers seeking to align with international quality standards. By offering a diverse portfolio of globally recognized brands, including Latamarko from Spain, MT Royal provides not only ingredients but also confidence—confidence that every shipment will perform reliably across production lines, support sustainable growth, and help Turkish manufacturers compete effectively in the global marketplace.

What is High Fat Cocoa Powder?

High fat cocoa powder is characterized by a cocoa butter content of 20%–24%, significantly higher than standard cocoa powders that contain around 10%–12%. This higher fat concentration delivers a richer flavor, deeper color, and smoother mouthfeel—qualities that make it indispensable in high-end chocolate production and bakery formulations.

Key Technical Advantages

- Creamier Texture: Enhanced fat levels improve mouthfeel and smoothness in coatings and fillings.

- Superior Flowability: Ensures easier processing during conching and tempering.

- Deeper Color: Provides a more intense visual appeal in baked or molded products.

- Better Fat Integration: Reduces the need for additional emulsifiers or stabilizers.

- Improved Product Stability: Extends shelf life through uniform fat distribution.

These functional advantages explain why high fat cocoa powder has become a preferred ingredient for large-scale manufacturers across Türkiye’s chocolate, biscuit, and dessert industries.

Türkiye’s Cocoa Industry: A Rapidly Expanding Market

Türkiye has emerged as one of the leading hubs for confectionery and bakery exports in the region, supplying premium chocolate and sweet products to over 150 countries. With this growth, ingredient quality and consistency have become non-negotiable factors in maintaining competitive production.

Manufacturers in cities such as Istanbul, Izmir, Bursa, and Gaziantep increasingly seek suppliers that can provide:

- Consistent quality aligned with international standards

- Reliable delivery and supply chain stability

- Technical documentation and traceability

- Compatibility with modern automated machinery

This is where experienced partners like MT Royal play a key role in bridging the gap between global cocoa expertise and the practical needs of Turkish factories.

MT Royal: Your Reliable Cocoa Powder Partner in Türkiye

MT Royal is a trusted distributor of natural, alkalized, and high fat cocoa powders from globally recognized producers. Our partnerships with renowned European brands—such as Latamarko from Spain—enable us to deliver products that meet the most demanding industrial requirements.

Manufacturers choose MT Royal because we prioritize:

- Stable Supply: Even during volatile market periods

- Technical Consistency: Batch-to-batch reliability for seamless production

- Competitive Pricing: Without compromising quality

- Comprehensive Support: From specification sheets to formulation advice

By combining technical expertise with market experience, MT Royal ensures every shipment supports productivity, performance, and profit.

Latamarko: European Excellence in Cocoa Powder Manufacturing

Latamarko, a premium Spanish-origin brand, represents European precision in cocoa ingredient engineering. Its high fat cocoa powders are widely recognized for:

- Uniform particle size for predictable behavior in mixing

- Deep and natural color tones retained after baking

- Rich, full-bodied flavor that enhances chocolate complexity

- Excellent dispersibility and reduced dusting during handling

For Turkish manufacturers aiming to produce export-grade confectionery, Latamarko offers the ideal balance between premium quality and process efficiency.

Technical Comparison of Cocoa Powder Grades

| Cocoa Powder Type | Fat Content | Color Profile | Flavor Intensity | Common Applications |

|---|---|---|---|---|

| Natural Cocoa Powder | 10–12% | Light Brown | Sharp and Fruity | Cakes, dry mixes, instant beverages |

| Alkalized Cocoa Powder | 10–12% | Reddish Brown to Dark Brown | Smooth and Balanced | Cocoa drinks, fillings, coatings |

| High Fat Cocoa Powder | 20–24% | Dark Brown to Deep Black | Rich and Creamy | Premium chocolates, spreads, coatings |

This table provides a technical overview for production engineers and formulators to choose the right cocoa powder grade based on their specific process and product type.

Industrial Benefits of Using High Fat Cocoa Powder

1. Enhanced Product Quality

High fat cocoa improves both taste and visual appeal, resulting in a premium consumer experience.

2. Increased Process Efficiency

Its smooth flow characteristics reduce machine wear and energy consumption during conching or mixing.

3. Better Yield Optimization

By partially replacing added fats or oils, manufacturers lower formulation costs while maintaining product richness.

4. Reduced Ingredient Complexity

It supports cleaner labeling and aligns with global demand for natural, simplified formulations.

Common Procurement Challenges and How to Avoid Them

- Inconsistent Fat Content – Always verify analytical data and supplier test reports before bulk purchasing.

- Improper Storage – High fat cocoa powder should be stored at 16–20°C with low humidity to prevent fat bloom.

- Focusing Solely on Price – Lower cost options may lead to production inefficiencies and higher waste.

- Ignoring Technical Documentation – Partner only with suppliers who provide complete specifications and traceability.

MT Royal ensures all these parameters are managed under strict quality control, offering reliability across every shipment.

Application Insights: High Fat Cocoa Powder in Turkish Manufacturing

Chocolate and Confectionery

Used in coatings, truffles, and molded chocolates for improved viscosity and a smoother finish.

Bakery and Biscuits

Provides darker color tones and richer flavors without excessive use of artificial colorants.

Beverages

Enhances creaminess and mouthfeel in premium instant cocoa drinks and dairy formulations.

Fillings and Spreads

Improves emulsion stability and prevents oil separation in nut-based or cocoa-based spreads.

Case Study: Efficiency Improvement in a Turkish Factory

A confectionery producer in Konya reported frequent production delays due to inconsistent cocoa powder flow. After switching to Latamarko high fat cocoa powder supplied by MT Royal, the factory observed:

- 15% reduction in production downtime

- More uniform color across product batches

- Smoother blending performance and faster cycle times

These improvements resulted in lower maintenance costs and higher production efficiency—demonstrating how premium ingredient selection directly impacts profitability.

Industry Trends in Türkiye’s Cocoa Sector

- Sustainability and Traceability: Manufacturers prefer ethically sourced, certified cocoa powders.

- Customization: Growing interest in tailored fat content and color grades.

- Automation: Advanced production lines require powders with precise flow and moisture properties.

- Export Orientation: Increasing focus on producing globally competitive, premium-grade confectionery.

High fat cocoa powder fits perfectly within these emerging industry needs, offering both quality and technical flexibility.

Expert Recommendations for Procurement Managers

- Test pilot batches in your specific production line before full-scale integration.

- Maintain long-term contracts with reliable suppliers to avoid market volatility.

- Request micro-biological and physical specification reports regularly.

- Monitor warehouse temperature and humidity to protect ingredient integrity.

- Work with partners offering technical guidance, not just product catalogs.

Frequently Asked Questions (FAQ)

1. What defines high-quality high fat cocoa powder?

Consistent fat content (20–24%), stable pH, low moisture (<5%), and fine particle distribution.

2. What is the difference between alkalized and natural cocoa powder?

Alkalized cocoa has a smoother taste and darker color; natural cocoa is lighter with a sharper flavor.

3. How should high fat cocoa powder be stored?

In a cool, dry environment (16–20°C) away from direct sunlight and humidity.

4. Can high fat cocoa powder reduce recipe fat content?

Yes, it allows manufacturers to reduce added fats by up to 10% without affecting quality.

5. Which brands are trusted in Türkiye?

Premium European suppliers like Latamarko, distributed by MT Royal, are preferred for consistency and performance.

Final Thoughts

The Turkish confectionery and bakery sector continues to evolve rapidly, driven by innovation, export demand, and quality expectations. In this competitive environment, using high fat cocoa powder from a trusted supplier like MT Royal can make the difference between average output and exceptional results.

Whether producing luxury chocolate coatings or mass-market biscuits, consistency and performance depend on raw material quality. By choosing reliable partners and premium European-grade cocoa powders such as Latamarko, manufacturers in Türkiye can ensure efficiency, stability, and superior flavor—cornerstones of sustainable growth in the modern food industry.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

Istanbul import export company

No comment