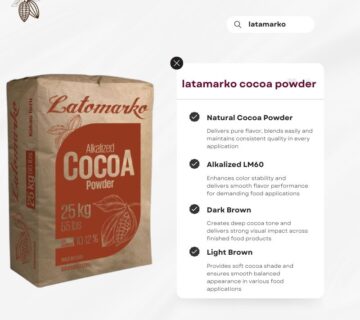

Natural Cocoa Powder:

Natural cocoa powder is a type of cocoa powder made from cocoa solids without undergoing the alkalization process. Here are key characteristics and uses of natural cocoa powder:

Characteristics:

- Alkalization: Unlike Dutch-processed cocoa powder, natural cocoa powder is not treated with an alkaline solution. As a result, it retains its original acidity.

- Color: Natural cocoa powder has a lighter color compared to alkalized cocoa powder. It typically ranges from light brown to reddish-brown.

- Flavor Profile: Retains the original and robust chocolate flavor of cocoa beans. The natural acidity in natural cocoa powder contributes to its distinct flavor profile.

- Acidity: Higher acidity compared to alkalized cocoa powder. This acidity can enhance the chocolatey and fruity notes in recipes.

- Leavening Agent in Baking: Natural cocoa powder is often used in recipes that require a leavening agent such as baking soda. The acidity in natural cocoa powder reacts with baking soda to produce carbon dioxide, which helps the baked goods rise.

- Applications: Natural cocoa powder is well-suited for a variety of baking applications, including cakes, brownies, cookies, and other chocolate-based desserts. It is also used in savory dishes and beverages.

Considerations:

- Flavor Intensity: Natural cocoa powder provides a more intense and fruity chocolate flavor compared to Dutch-processed cocoa powder.

- Color: Its lighter color can impact the visual appearance of certain recipes, making it suitable for desserts where a lighter color is preferred.

- Baking Characteristics: When using natural cocoa powder in recipes, adjustments may be needed for leavening agents and acidity, especially if the recipe originally calls for Dutch-processed cocoa.

Storage:

- Natural cocoa powder should be stored in a cool, dry place to maintain its quality and prevent clumping.

Note: The choice between natural and alkalized cocoa powder depends on the desired characteristics in the final product. Natural cocoa powder is preferred for recipes where the original acidity and intense chocolate flavor are desired.

- Composition:

- Cocoa Solids: Percentage of cocoa solids, which include cocoa powder’s non-fat components.

- Cocoa Butter: Percentage of cocoa butter in the cocoa powder.

- Flavor Profile:

- Intensity: Assess the intensity of the chocolate flavor, which tends to be more robust and fruity in natural cocoa powder due to the retained acidity.

- Aroma: Evaluate the aroma, considering the distinctive chocolate notes.

- Color:

- Hue: Describe the color of the cocoa powder, which typically ranges from light brown to reddish-brown. Compare it to a standard color chart if needed.

- Consistency: Check for uniform color throughout the sample.

- Acidity:

- pH Level: Measure the pH level to quantify the acidity. Natural cocoa powder typically has a lower pH compared to alkalized cocoa powder.

- Particle Size:

- Particle Distribution: Analyze the particle size distribution, which can impact the cocoa powder’s solubility and texture in various applications.

- Moisture Content:

- Moisture Percentage: Determine the moisture content, as higher moisture can lead to clumping and affect the powder’s shelf life.

- Microbiological Analysis:

- Microbial Load: Conduct tests for microbial content to ensure product safety and quality.

- Contaminant Analysis:

- Heavy Metals: Check for the presence of heavy metals, ensuring that the cocoa powder meets safety standards.

- Storage Stability:

- Fat Bloom Resistance: Assess the cocoa powder’s resistance to fat bloom, a whitish coating that can appear on the surface due to changes in fat crystal structure.

- Functional Properties:

- Solubility: Evaluate how well the cocoa powder dissolves in liquids.

- Color Stability: Assess the stability of the color during processing and storage.

- Baking Characteristics:

- Leavening Properties: Evaluate how the cocoa powder interacts with leavening agents like baking soda.

- Texture Contribution: Analyze how it contributes to the texture of baked goods.

- Sensory Evaluation:

- Panel Testing: Conduct sensory evaluations with a trained panel to assess flavor, aroma, and overall quality.

- Packaging and Labeling Compliance:

- Packaging Integrity: Ensure that the packaging protects the cocoa powder from moisture and contaminants.

- Label Accuracy: Verify that the product’s label accurately represents its composition and attributes.

It’s important to note that these analyses can be conducted using various laboratory techniques and equipment, and they may vary depending on the specific requirements of the manufacturer or regulatory standards. Additionally, compliance with food safety regulations and industry standards is crucial in the production and distribution of cocoa powder.

No comment