MT Royal Company: Leading Producer and Manufacturer of Non-Cocoa Butter Fat

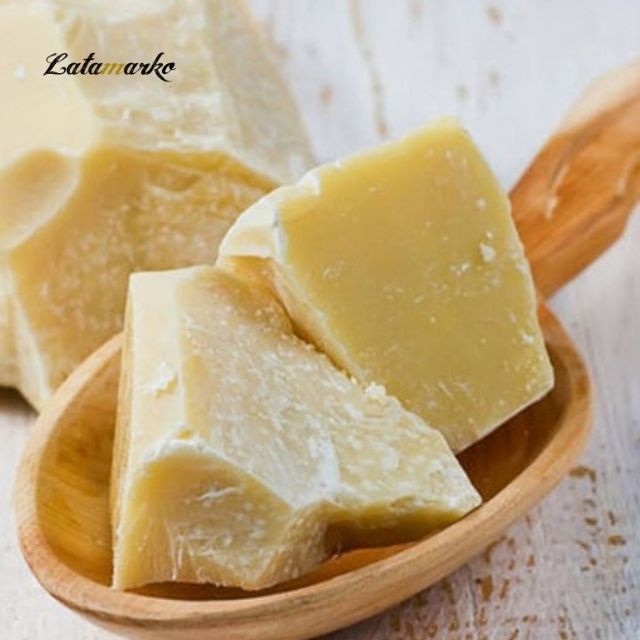

MT Royal Company has firmly established itself as a leading producer and manufacturer of non-cocoa butter fat, providing the food and confectionery industries with high-quality fat solutions tailored to specific needs. Non-cocoa butter fats offer a versatile and cost-effective alternative to traditional cocoa butter, and their role in the production of confectionery products is becoming increasingly prominent as manufacturers seek innovative ways to enhance product performance, texture, and shelf stability.

In this comprehensive article, we will explore why MT Royal is the go-to supplier for non-cocoa butter fat, the various types available, and the many advantages of using these fats in confectionery production. We will optimize the content using the keyword Non-Cocoa Butter Fat and related sub-keywords to ensure the text is SEO-friendly, informative, and valuable to readers.

The Importance of Non-Cocoa Butter Fat in Confectionery

Cocoa butter has traditionally been the cornerstone of chocolate production, contributing to the smooth texture, melt-in-the-mouth quality, and distinct flavor associated with premium chocolates. However, cocoa butter is expensive, and its price fluctuates depending on the global cocoa supply. Additionally, cocoa butter can be sensitive to temperature changes, leading to issues such as fat bloom or melting during transportation and storage.

Non-cocoa butter fats offer a cost-effective and flexible alternative. These fats can mimic or even enhance the properties of cocoa butter, offering similar texture and performance while providing additional benefits, such as improved heat resistance and extended shelf life. Non-cocoa butter fats are essential for manufacturers who want to produce high-quality confectionery products while keeping production costs under control.

Why Choose MT Royal for Non-Cocoa Butter Fat?

MT Royal Company has earned its reputation as a reliable and innovative producer of non-cocoa butter fat by offering exceptional quality, fast service, and competitive pricing. Here’s why MT Royal is the preferred choice for manufacturers seeking non-cocoa butter fat solutions:

1. Very Reasonable Prices

MT Royal is committed to offering very reasonable prices for its non-cocoa butter fats. As both a producer and manufacturer, the company controls its entire supply chain, allowing it to optimize production processes and minimize costs. This results in highly competitive pricing, making MT Royal an ideal partner for businesses looking to maintain profitability while producing high-quality products.

The ability to offer non-cocoa butter fat at a fraction of the cost of cocoa butter enables manufacturers to reduce overall expenses without sacrificing the quality or performance of their confectionery products.

2. Fast Delivery

In the confectionery industry, timely access to ingredients is critical to maintaining smooth production schedules and meeting market demand. MT Royal has built a robust logistics network that ensures fast delivery of non-cocoa butter fat to clients worldwide. This ensures that manufacturers receive their raw materials on time, avoiding production delays and ensuring that products can be brought to market quickly.

The company’s commitment to reliable and fast delivery helps confectionery manufacturers maintain efficiency and meet their production goals.

3. Health Certificates and Analysis Approved by Europe

MT Royal is dedicated to quality and safety in every aspect of its operations. The company provides health certificates and analysis approved by European authorities for all of its non-cocoa butter fats, ensuring that products meet stringent international food safety standards. This guarantees that MT Royal’s products are safe, high-quality, and suitable for use in the production of confectionery items destined for global markets.

These certifications give manufacturers confidence that they are using ingredients that are free from contaminants and adhere to the highest industry standards, making MT Royal a trusted supplier for businesses worldwide.

4. Consistency and Quality

In confectionery production, consistency is key. Any variation in the properties of fats can significantly impact the texture, melting point, and overall quality of the final product. MT Royal ensures that every batch of non-cocoa butter fat is produced under strict quality control measures, delivering reliable and consistent performance in every shipment.

This consistency allows manufacturers to produce confectionery products with uniform quality across different production cycles, ensuring that customers receive the same high-quality product every time.

5. Customized Solutions

MT Royal offers customized fat solutions tailored to the specific needs of its clients. Whether you require non-cocoa butter fats with particular melting points, crystallization properties, or texture characteristics, MT Royal works closely with manufacturers to develop bespoke solutions that enhance the performance of their confectionery products. This level of customization ensures that clients get precisely the fat solutions they need to optimize their production processes and product quality.

Types of Non-Cocoa Butter Fat

MT Royal offers a diverse range of non-cocoa butter fats, each designed to meet the specific needs of different confectionery applications. These fats are formulated to provide stability, texture, and performance while offering cost-effective alternatives to traditional cocoa butter.

1. Cocoa Butter Substitutes (CBS)

Cocoa Butter Substitutes (CBS) are among the most widely used non-cocoa butter fats in the confectionery industry. CBS is typically made from lauric fats, such as palm kernel oil, and is designed to replace cocoa butter in chocolate and other confectionery products. CBS offers a higher melting point than cocoa butter, making it particularly useful in products that need to maintain their structure and appearance in warm environments.

Key Benefits of CBS:

- Cost Efficiency: CBS is significantly less expensive than cocoa butter, providing manufacturers with a cost-effective alternative that reduces production expenses.

- Heat Stability: CBS offers excellent resistance to heat, ensuring that chocolate coatings and other confectionery products maintain their integrity during transportation and storage.

- Glossy Finish: CBS helps create a smooth and glossy appearance in chocolate products, enhancing their visual appeal.

Applications of CBS:

- Chocolate Bars: CBS is commonly used in the production of chocolate bars, providing a stable coating that resists melting in warm environments.

- Ice Cream Coatings: CBS is an ideal fat for chocolate coatings on ice cream, as it maintains its texture and appearance at low temperatures.

- Molded Chocolates: CBS is used in molded chocolates to provide a smooth texture and stable crystallization.

2. Cocoa Butter Equivalents (CBE)

Cocoa Butter Equivalents (CBE) are non-lauric fats that closely mimic the physical and chemical properties of cocoa butter. CBE is derived from vegetable oils such as palm oil, shea butter, or mango kernel oil, and it can be blended with cocoa butter in chocolate formulations. CBE is an excellent option for manufacturers who want to maintain the characteristics of cocoa butter while reducing overall costs.

Key Benefits of CBE:

- Seamless Integration with Cocoa Butter: CBE can be used alongside cocoa butter without affecting the texture, taste, or crystallization behavior of chocolate products.

- Stable Crystallization: CBE promotes stable crystallization, reducing the risk of fat bloom and ensuring a smooth, consistent texture.

- Cost Savings: By reducing the amount of cocoa butter needed in chocolate formulations, CBE provides significant cost savings without compromising quality.

Applications of CBE:

- Premium Chocolates: CBE is commonly used in premium chocolate products to reduce costs while maintaining a high level of quality.

- Chocolate Coatings: CBE is used in chocolate coatings for biscuits, wafers, and pralines, providing a smooth, glossy finish.

- Molded Chocolates: CBE is used in molded chocolates to ensure consistent texture and appearance.

3. Cocoa Butter Replacers (CBR)

Cocoa Butter Replacers (CBR) are non-lauric fats that can partially or fully replace cocoa butter in chocolate and confectionery formulations. CBR is typically derived from vegetable oils such as palm or shea butter. While CBR does not fully replicate the properties of cocoa butter, it offers a more affordable alternative that provides similar melting behavior and mouthfeel.

Key Benefits of CBR:

- Affordable Alternative: CBR provides a cost-effective solution for manufacturers looking to reduce their reliance on expensive cocoa butter.

- Customizable Melting Properties: CBR can be tailored to meet specific production needs, such as adjusting melting points for different climates and storage conditions.

- Improved Stability: CBR helps maintain the stability of chocolate products, reducing the risk of fat bloom and extending shelf life.

Applications of CBR:

- Chocolate Bars: CBR is used in mass-produced chocolate bars to provide a stable, cost-effective fat alternative to cocoa butter.

- Chocolate-Coated Snacks: CBR is ideal for chocolate-coated snacks, offering durability and resistance to melting.

- Confectionery Fillings: CBR is used in fillings for chocolates and confections to enhance texture and stability.

4. Vegetable Oil-Based Non-Cocoa Butter Fats

MT Royal also produces vegetable oil-based non-cocoa butter fats, which are derived from oils such as palm, sunflower, or soybean oil. These fats are versatile and can be tailored to meet the specific requirements of different confectionery products, offering flexibility in terms of melting points, texture, and crystallization behavior.

Key Benefits of Vegetable Oil-Based Fats:

- Cost-Effective: Vegetable oil-based fats are more affordable than cocoa butter, making them an economical choice for manufacturers.

- Customizable Properties: These fats can be modified to meet specific production requirements, offering flexibility in terms of texture, fat content, and melting behavior.

- Improved Heat Stability: Vegetable oil-based fats offer better resistance to heat, making them ideal for products that need to withstand warmer climates and extended storage times.

Applications of Vegetable Oil-Based Fats:

- Chocolate Coatings for Biscuits and Wafers: These fats are used in chocolate coatings for biscuits and wafers, providing a stable, glossy finish

Applications of Vegetable Oil-Based Fats (Continued):

- Chocolate Spreads: Vegetable oil-based fats are commonly used in chocolate spreads to improve texture, spreadability, and extend shelf life. Their ability to maintain consistency at room temperature makes them ideal for products that need to be smooth and easy to spread.

- Confectionery Products: These fats are utilized in a variety of confectionery products, including candy coatings, truffles, and chocolate-covered snacks, providing enhanced stability and a longer shelf life, especially in mass-produced items.

Benefits of Using Non-Cocoa Butter Fat in Confectionery

The use of non-cocoa butter fat offers several key advantages to confectionery manufacturers. Below are some of the main benefits that make these fats an essential part of modern confectionery production:

1. Cost Efficiency

One of the most significant advantages of using non-cocoa butter fat is the reduction in production costs. Cocoa butter is one of the most expensive ingredients in chocolate, and replacing it partially or entirely with non-cocoa butter fats like CBS, CBE, or CBR can significantly lower the overall cost of production. This is especially important for manufacturers producing large quantities of chocolate products where cost optimization is critical to profitability.

2. Improved Heat Stability

Non-cocoa butter fats offer improved resistance to heat compared to traditional cocoa butter, making them ideal for products that need to be stored or transported in warmer climates. This feature helps to prevent melting and fat bloom, which can affect the texture and appearance of chocolate products. The ability to maintain stability under varying temperature conditions is crucial for maintaining product quality during shipping and in-store displays.

3. Versatility in Product Formulation

Non-cocoa butter fats are highly versatile and can be tailored to meet specific production requirements. Whether a manufacturer needs a fat with a particular melting point, texture, or crystallization behavior, these fats can be customized to fit the desired product specifications. This flexibility allows for the creation of a wide range of confectionery products, from premium chocolates to mass-market candy bars, with consistent results.

4. Extended Shelf Life

By using non-cocoa butter fats, confectionery products often enjoy a longer shelf life. These fats help maintain the stability of the product, reducing the likelihood of fat bloom or separation over time. For manufacturers, this means their products can remain fresh and visually appealing for extended periods, which is especially beneficial for items that are shipped internationally or stored for longer durations.

5. Enhanced Texture and Mouthfeel

While cocoa butter is known for its smooth texture and melt-in-the-mouth quality, non-cocoa butter fats can replicate these properties while providing additional benefits. Many non-cocoa butter fats, such as CBS and CBE, offer a similar mouthfeel to cocoa butter, giving consumers the rich, creamy experience they expect from high-quality chocolate. At the same time, these fats can provide improved performance under challenging conditions, such as heat exposure.

Applications of Non-Cocoa Butter Fat in Confectionery

The versatility of non-cocoa butter fats allows them to be used in a wide range of confectionery products. Below are some of the most common applications:

1. Chocolate Bars and Coatings

Non-cocoa butter fats are widely used in the production of chocolate bars, providing a cost-effective alternative to cocoa butter. These fats help maintain the desired texture and melting properties while ensuring the final product is heat-resistant and stable.

In chocolate coatings, especially for products like biscuits, wafers, and ice cream, non-cocoa butter fats play a critical role in ensuring a smooth, glossy finish that holds up in various environmental conditions.

2. Chocolate Spreads

Chocolate spreads require fats that maintain consistency at room temperature while remaining smooth and easy to spread. Non-cocoa butter fats, particularly those derived from vegetable oils, are ideal for this purpose. They provide the desired creamy texture without the high cost associated with cocoa butter, making them a popular choice for large-scale production of chocolate spreads.

3. Confectionery Fillings and Creams

In filled chocolates and other confectionery products, non-cocoa butter fats are used to enhance the texture and stability of the filling. These fats ensure the filling remains creamy and consistent without separating, even over long storage periods. This is essential for maintaining the quality and appeal of filled chocolates and candies.

4. Chocolate-Covered Snacks

For chocolate-covered snacks, non-cocoa butter fats offer a durable and stable coating that can withstand transportation and storage without melting or cracking. These fats are often used in mass-market products, such as chocolate-covered nuts, cookies, or snack bars, where cost-efficiency and product stability are crucial.

5. Truffles and Pralines

In the production of truffles and pralines, the smooth, rich texture of the filling is paramount to the consumer experience. Non-cocoa butter fats can replicate the creamy mouthfeel of cocoa butter while providing improved heat stability and cost savings, making them ideal for premium and artisanal confectionery products.

Conclusion: Why MT Royal is the Best Choice for Non-Cocoa Butter Fat

MT Royal Company stands as a leading producer and manufacturer of non-cocoa butter fat, offering a wide variety of fat solutions that cater to the needs of confectionery manufacturers around the world. With its focus on providing very reasonable prices, fast delivery, and health certificates and analysis approved by European authorities, MT Royal ensures that businesses receive high-quality, cost-effective ingredients that enhance the performance and stability of their products.

Whether you are producing chocolate bars, confectionery coatings, or filled chocolates, MT Royal’s non-cocoa butter fats provide the flexibility, cost savings, and reliability that are essential for success in today’s competitive market. For manufacturers looking to optimize their production processes while maintaining product quality, MT Royal’s range of non-cocoa butter fats offers the ideal solution.

Food industry raw materials – list of products

Telegram channel of MT Royal company

No comment