For modern manufacturing facilities, sourcing high-quality ingredients is far more than a procurement exercise—it’s a strategic decision that can affect cost-efficiency, product consistency, and market positioning. Among critical ingredients, organic cocoa powder stands out for its dual role: it offers both the rich flavor essential for premium chocolate and confectionery products and the credibility of organic certification for health-conscious consumers.

Türkiye has emerged as a key hub for sourcing organic cocoa powder in bulk. Its unique position—bridging Europe, Asia, and the Middle East—combined with sophisticated processing facilities, makes it an ideal base for manufacturers seeking reliable, cost-effective, and high-quality cocoa powder supply.

At MT Royal, we’ve witnessed firsthand how manufacturers benefit from strategic sourcing in Türkiye. From large-scale bakeries to industrial chocolate producers, factories rely on a consistent supply of organic cocoa powder to maintain both product quality and operational efficiency. In this guide, we’ll dive deep into definitions, procurement strategies, industrial best practices, pitfalls to avoid, and premium brand insights, including the Spanish-origin Latamarko, without ever feeling like a sales pitch.

What Is Organic Cocoa Powder?

Fundamentals of Production

Organic cocoa powder is made from cocoa beans grown according to organic agriculture standards, which restrict synthetic fertilizers, pesticides, and GMOs. The beans undergo a meticulous process:

- Fermentation: Beans are naturally fermented to develop flavor.

- Roasting: Precise roasting ensures flavor consistency and reduces microbial load.

- Grinding and Pressing: Cocoa solids are separated from cocoa butter.

- Powdering: The remaining solids are ground into a fine, consistent powder.

Organic certification ensures traceability, meaning every batch can be traced back to its farm of origin—vital for industrial buyers needing documentation for regulatory compliance and export requirements.

Industrial-Grade Specifications

Unlike retail cocoa powders, industrial organic cocoa powder is formulated for high-volume production. Key parameters include:

- Fat content (usually 10–22%) for proper emulsification

- Particle size for flow consistency in mixers and silos

- Moisture content under 5% to prevent clumping

- Color uniformity to maintain product aesthetics

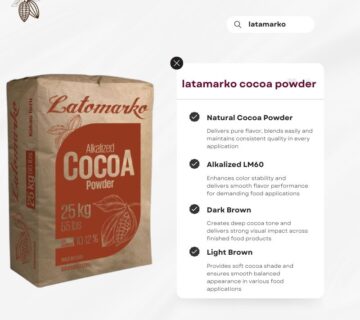

Premium brands like Latamarko often offer tight specifications, ensuring reliable performance in high-end chocolate and confectionery lines.

Benefits of Organic Cocoa Powder for Manufacturing Facilities

1. Consistent Product Quality

Industrial production depends on repeatability. Organic cocoa powder from certified Turkish suppliers offers uniform flavor, color, and solubility, which reduces batch-to-batch variation.

2. Marketing Advantage with Organic Certification

Organic certification is not just a label—it’s a value proposition for end consumers. By sourcing organic cocoa powder, manufacturers can target health-conscious and premium markets, opening new revenue streams.

3. Operational Efficiency

Bulk, well-graded organic cocoa powder flows smoothly through industrial hoppers and conveyors, minimizing downtime, clogs, and material wastage. Properly sourced powder reduces cleaning frequency and enhances production uptime.

4. Enhanced Product Application

Organic cocoa powder is ideal for:

- Baked goods: cakes, cookies, and pastries

- Confectionery: truffles, chocolate coatings, and fillings

- Beverages: hot cocoa mixes and protein blends

- Functional foods: protein bars, dairy blends, and vegan desserts

Its rich aroma, deep color, and stable composition make it versatile for industrial applications.

Common Pitfalls in Industrial Procurement

Industrial buyers often face hidden challenges when sourcing organic cocoa powder. Some common mistakes include:

1. Focusing Solely on Price

Cheap cocoa powder may have inconsistent fat content, uneven particle size, or variable alkalization, leading to production inefficiencies.

2. Ignoring Supplier Traceability

Without verified certification, batches may fail audits or export regulations, resulting in lost revenue and production delays.

3. Overlooking Storage Requirements

Organic cocoa powder is hygroscopic. Improper storage can cause clumping, microbial growth, and color changes. Factories must maintain controlled humidity, temperature, and sealed containers.

4. Neglecting Logistics and Lead Times

Even Türkiye’s proximity can’t prevent shipping delays, especially for bulk orders. Planning 8–12 week lead times ensures uninterrupted production.

Step-by-Step Guide for Factory Managers and Procurement Officers

Step 1: Define Material Specifications

- Fat content: 10–22%

- Particle size: 15–25 microns typical for industrial lines

- Moisture content: <5%

- Color consistency: critical for premium chocolate

Step 2: Identify and Vet Suppliers

- Ensure organic certification (EU, USDA, or local Turkish standards)

- Audit production facilities for HACCP and ISO 22000 compliance

- Evaluate historical delivery reliability

Step 3: Pilot Test Samples

- Small-scale testing in your production line verifies flow, blend uniformity, and taste

- Adjust formulations if needed before full-scale adoption

Step 4: Calculate Total Landed Cost

Include:

- FOB price and shipping

- Customs duties

- Storage, handling, and buffer stock

- Quality verification expenses

Step 5: Establish Inventory Buffers

- Maintain 4–6 weeks of stock

- Store in temperature- and humidity-controlled warehouses

Step 6: Monitor Supplier Performance

- Track shipment timeliness

- Measure deviation from specifications

- Evaluate impact on production metrics like downtime and scrap

Real-World Example: MT Royal’s Supply Solutions

At MT Royal, we supply manufacturers with a comprehensive range of brands, balancing cost-efficiency and premium quality. For instance, factories using Turkish organic cocoa powder for standard chocolate lines often complement their premium products with Latamarko batches. This ensures that consumer-facing products maintain top-tier quality, while bulk production remains cost-efficient.

We’ve observed clients reduce downtime by 15% after implementing structured supplier vetting, batch testing, and storage protocols. This demonstrates that strategic sourcing and process control can directly influence operational performance and profitability.

Industry-Specific Considerations for Large-Scale Production

- Powder Flow: Fine organic powders can accumulate static charge. Proper conveyors and anti-static measures prevent blockages.

- Blend Stability: Uniform fat and moisture content ensures seamless integration with other ingredients.

- Quality Segmentation: Use standard Turkish bulk for cost-sensitive production, and premium brands for high-margin, export-oriented products.

- Supply Chain Resilience: Maintain multiple suppliers to mitigate harvest fluctuations and logistical delays.

Comparison Table: Turkish Bulk vs Premium European Organic Cocoa Powder

| Feature | Turkish Bulk Organic Cocoa | Premium European (Latamarko) |

|---|---|---|

| Cost | Lower | Higher |

| Specification Consistency | Good, may vary slightly | Very tight |

| Particle Size | Standard industrial | Ultra-fine for premium applications |

| Certification | EU Organic, local | EU, USDA Organic, ISO standards |

| Delivery Lead-Time | Moderate | Predictable |

| Ideal Use | Mass production | Premium chocolate and confectionery |

| Downtime Risk | Moderate | Low |

Frequently Asked Questions (FAQ)

Q1: What is the difference between organic and conventional cocoa powder?

A1: Organic cocoa powder is sourced from farms without synthetic fertilizers or GMOs, certified for traceability and sustainability.

Q2: Can organic cocoa powder be used in all recipes?

A2: Yes, but slight adjustments in fat content and alkalization may be needed for optimal taste and texture.

Q3: How should organic cocoa powder be stored in industrial environments?

A3: Cool, dry, low-humidity conditions, preferably in sealed big bags or silos.

Q4: Why consider Latamarko for premium lines?

A4: It offers tight tolerances, uniform color, and consistent solubility, ideal for high-end chocolate or export products.

Q5: How does MT Royal support industrial buyers?

A5: By providing bulk sourcing, quality audits, multiple brand options, and competitive pricing, we help factories achieve both efficiency and premium product standards.

Conclusion

Sourcing organic cocoa powder wholesale in Türkiye is more than a procurement task—it’s a strategic operational decision. By implementing clear specifications, robust supplier vetting, and quality control measures, industrial buyers can reduce downtime, optimize production, and ensure consumer-grade product quality.

In our experience at MT Royal, manufacturers benefit from a dual approach: Turkish bulk for cost-effective production, and Latamarko for premium, high-margin product lines. When every batch of cocoa powder is predictable, traceable, and high-quality, manufacturers gain more than efficiency—they gain reliability, brand integrity, and market competitiveness.

latamarko alkalized cocoa powder lm60

cocoa powder for chocolate production-Best price

Food industry raw materials – list of products

Types of Gelatin from Turkish Manufacturer

Alkalized Cocoa Powder Bulk Supplier

No comment