The automotive industry constantly demands lighter, stronger, and more efficient components. This persistent need has propelled aluminum casting auto parts manufacturer companies to the forefront of innovation. Aluminum casting offers a superior solution due to its exceptional strength-to-weight ratio, corrosion resistance, and versatility. These properties are crucial for enhancing vehicle performance, improving fuel efficiency, and reducing emissions. As a key player in this dynamic sector, MT Royal has established itself as a reliable source for high-quality custom manufacturing of aluminum auto parts. Our commitment to advanced technology and stringent quality control ensures that we deliver products that not only meet but exceed industry expectations. MT Royal understands the intricate demands of automotive manufacturing and provides tailored solutions that contribute to the overall success of our clients’ projects. We are dedicated to pushing the boundaries of what is possible in aluminum casting.

The Role of an Aluminum Casting Auto Parts Manufacturer

The role of an Aluminum Casting Auto Parts Manufacturer is pivotal in the modern automotive supply chain. These specialized manufacturers are responsible for transforming raw aluminum into precise and functional components used in various parts of a vehicle. This process involves sophisticated design, meticulous mold creation, and precise casting techniques, often utilizing high-pressure die casting, sand casting, or gravity casting methods. Each method offers distinct advantages depending on the complexity, volume, and specific performance requirements of the part. An experienced manufacturer like MT Royal possesses the expertise to select the most appropriate casting method to ensure optimal results. We collaborate closely with automotive designers and engineers to ensure that the final product seamlessly integrates into the vehicle’s overall architecture. Our involvement starts from the initial concept phase, moving through detailed design and prototyping, all the way to mass production. This comprehensive approach ensures that every part is manufactured to the highest standards.

۹

۹

Advantages of Aluminum Casting Auto Parts

Aluminum casting offers a myriad of advantages that make it an ideal choice for automotive components, making an Aluminum Casting Auto Parts Manufacturer an invaluable partner. Firstly, the most significant benefit is the remarkable weight reduction. Aluminum is significantly lighter than steel, which directly translates to improved fuel efficiency and reduced carbon emissions, a critical concern in today’s environmentally conscious world. Secondly, aluminum possesses excellent corrosion resistance, which is vital for parts exposed to harsh environmental conditions, extending the lifespan of the vehicle and reducing maintenance costs. Thirdly, aluminum parts offer superior thermal conductivity, essential for components like engine blocks and heat sinks that need to dissipate heat efficiently. Furthermore, aluminum casting allows for the creation of complex geometries with high precision, enabling the consolidation of multiple parts into a single casting. This simplification reduces assembly time and costs, while also improving the structural integrity of the component. MT Royal leverages these inherent advantages to produce parts that are both high-performing and cost-effective. We understand that the future of automotive design leans heavily on lightweight and durable materials.

Product Specifications

As a leader in Custom Manufacturing, MT Royal adheres to rigorous specifications for all aluminum casting auto parts. Our production processes are meticulously controlled to ensure consistency and quality across every batch. We work with a variety of aluminum alloys, including A356, A380, and A413, each selected based on the specific application requirements for strength, ductility, and castability. The design phase incorporates advanced CAD/CAM software for precise modeling and simulation, allowing us to identify and mitigate potential issues before physical production begins. Our casting operations are equipped with state-of-the-art machinery, including automated die-casting machines and robotic handling systems, which guarantee high precision and repeatability. Surface finishes are carefully controlled to meet aesthetic and functional requirements, ranging from smooth, polished surfaces to textured finishes for better grip or paint adhesion. Furthermore, post-casting processes such as machining, heat treatment, and surface coating are performed in-house to maintain strict quality control and optimize material properties. All products undergo comprehensive testing, including dimensional checks, material analysis, and non-destructive testing, to ensure they meet the exact specifications agreed upon with our clients. We pride ourselves on our ability to produce parts that consistently meet the highest industry standards.

Applications of Aluminum Casting Auto Parts

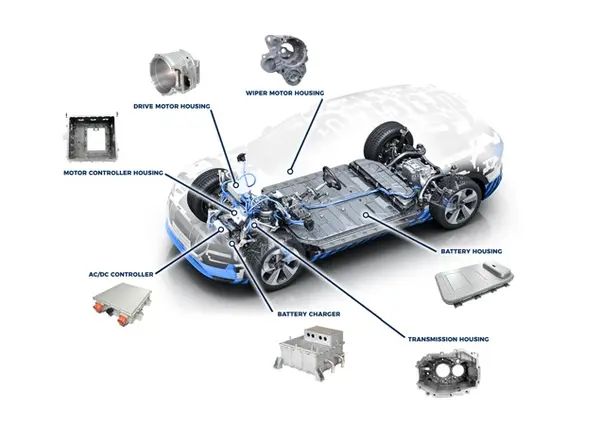

The versatility of aluminum casting makes it suitable for a vast array of automotive applications, benefiting from the expertise of an Aluminum Casting Auto Parts Manufacturer. These parts are integral to nearly every system within a vehicle. In the engine compartment, aluminum castings are used for cylinder heads, engine blocks, intake manifolds, and oil pans due to their excellent heat dissipation properties and lightweight characteristics. For the chassis and suspension system, components like control arms, knuckles, and subframes benefit from aluminum’s strength and ability to reduce unsprung weight, significantly improving vehicle handling and ride comfort. Furthermore, aluminum castings are commonly found in transmission housings, brake calipers, and various structural components, contributing to overall vehicle safety and performance. Electric vehicles also rely heavily on aluminum castings for battery housings, motor casings, and inverter enclosures, where weight reduction and thermal management are paramount. MT Royal’s custom manufacturing capabilities allow us to produce a diverse range of these critical components, tailored precisely to the unique demands of each application. We support both traditional internal combustion engines and the rapidly expanding electric vehicle market.

Purchasing this Product from MT Royal

When it comes to sourcing high-quality aluminum casting auto parts, purchasing from MT Royal ensures unparalleled reliability and expertise. As an experienced Custom Manufacturing provider, we offer a streamlined process from initial inquiry to final delivery. Our sales and engineering teams work collaboratively with clients to understand their specific needs, providing expert guidance on material selection, design optimization, and manufacturing feasibility. We offer competitive pricing while maintaining the highest quality standards, ensuring excellent value for your investment. MT Royal’s robust supply chain and efficient production scheduling mean that we can meet demanding deadlines and accommodate varying order volumes, from small prototype runs to large-scale mass production. We prioritize clear communication and transparency throughout the entire project lifecycle, keeping you informed at every stage. Our commitment to customer satisfaction is paramount, and we strive to build long-term partnerships based on trust and mutual success. Choosing MT Royal means opting for a partner that understands the intricacies of the automotive industry and is dedicated to delivering superior products.

Conclusion

The automotive industry’s continuous evolution highlights the indispensable role of an expert Aluminum Casting Auto Parts Manufacturer. Aluminum casting remains a vital technology, driving advancements in vehicle performance, fuel efficiency, and environmental sustainability. MT Royal stands as a testament to excellence in this field, offering comprehensive custom manufacturing solutions that meet the stringent demands of modern automotive production. Our dedication to quality, precision, and customer satisfaction ensures that we deliver superior aluminum components for a wide range of applications. By partnering with MT Royal, businesses gain access to cutting-edge technology, unparalleled expertise, and a commitment to innovation that will help them navigate the challenges and opportunities of the future automotive landscape. We are confident that our capabilities will continue to support the industry’s drive towards lighter, stronger, and more efficient vehicles.

The Future of Aluminum Casting in Automotive Manufacturing

The future of aluminum casting in automotive manufacturing looks incredibly promising, cementing the importance of every Aluminum Casting Auto Parts Manufacturer. Innovations in material science are leading to the development of new aluminum alloys with even greater strength, ductility, and fatigue resistance, pushing the boundaries of what is achievable. Advances in casting technologies, such as vacuum die casting and semi-solid casting, are enabling the production of even more complex and defect-free parts. Furthermore, the increasing demand for electric vehicles (EVs) will significantly boost the need for lightweight aluminum components for battery enclosures, motor housings, and structural frames, where weight reduction is crucial for maximizing range and efficiency. Automation and artificial intelligence are also playing an increasing role in optimizing the casting process, leading to higher precision, reduced waste, and faster production cycles. As the automotive industry continues its rapid transformation, an Aluminum Casting Auto Parts Manufacturer like MT Royal will remain at the forefront, adapting to new challenges and embracing emerging technologies to deliver the next generation of automotive components.

Reviews

There are no reviews yet.