In today’s fast-paced manufacturing landscape, the demand for efficient, high-performance, and cost-effective tooling solutions is paramount. Aluminum tooling castings have emerged as a cornerstone in various industries, offering a unique blend of strength, lightweight properties, and thermal conductivity. As a prominent Aluminum Tooling Castings Manufacturer, MT Royal has established itself as a reliable partner for businesses seeking top-tier tooling components. Our commitment to precision engineering and advanced manufacturing techniques ensures that our clients receive products that meet the most stringent quality standards. We understand the critical role these castings play in optimizing production processes and reducing lead times, making MT Royal an invaluable asset to any manufacturing operation. Our extensive experience and dedication to innovation allow us to consistently deliver solutions that drive efficiency and profitability for our customers.

Unveiling the Product: Advanced Aluminum Tooling Castings from MT Royal

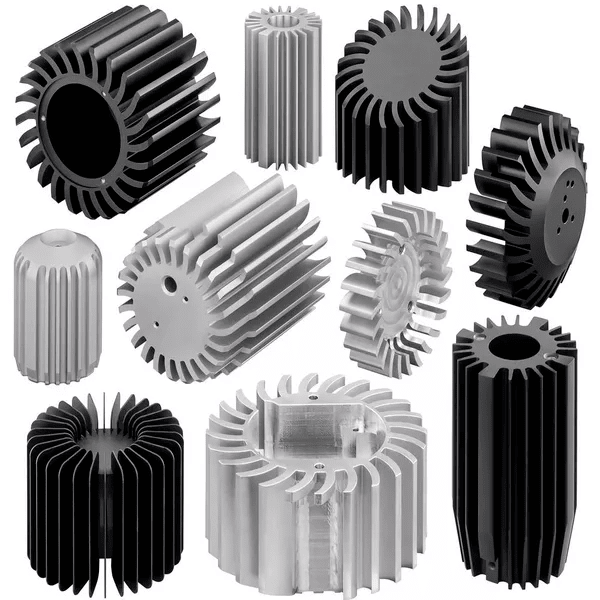

MT Royal specializes in the production of advanced aluminum tooling castings, engineered to meet the diverse needs of modern industries. These castings are manufactured using state-of-the-art processes, ensuring exceptional dimensional accuracy and structural integrity. Our product range encompasses a variety of sizes and complexities, from intricate prototypes to large-scale production tools. We leverage cutting-edge design software and simulation tools to optimize the performance of each casting before it even enters production. This meticulous approach guarantees that every product leaving our facility is robust, reliable, and perfectly suited for its intended application. Furthermore, the inherent properties of aluminum, such as its excellent machinability and resistance to corrosion, make our castings a superior choice for a multitude of tooling requirements. MT Royal‘s commitment to quality is evident in every piece we produce, providing a solid foundation for your manufacturing success.

Advantages of Choosing Aluminum Tooling Castings

The benefits of utilizing aluminum tooling castings are numerous and contribute significantly to overall manufacturing efficiency and cost savings. Firstly, aluminum’s lightweight nature reduces the overall weight of tools, making them easier to handle and contributing to lower operational costs and improved ergonomics. Secondly, its superior thermal conductivity allows for faster heating and cooling cycles in processes like injection molding, significantly decreasing cycle times and boosting productivity. This rapid heat transfer also helps in achieving uniform temperature distribution, leading to higher quality finished products with fewer defects. Thirdly, the excellent machinability of aluminum reduces the time and cost associated with post-casting operations, accelerating tool production. Finally, aluminum tooling offers good wear resistance and dimensional stability, ensuring a longer lifespan for the tools and reducing the frequency of replacements. These combined advantages make aluminum tooling castings a highly economical and efficient choice for various industrial applications.

Product Specifications: Precision and Performance

Our aluminum tooling castings are manufactured to precise specifications, ensuring optimal performance and longevity. MT Royal employs strict quality control measures at every stage of the production process, from material selection to final inspection. We utilize high-grade aluminum alloys, carefully chosen for their specific mechanical properties and suitability for tooling applications. Our casting processes, including sand casting, permanent mold casting, and low-pressure casting, are selected based on the specific requirements of the tool, ensuring the best possible outcome. Each casting undergoes rigorous testing, including dimensional checks, metallurgical analysis, and non-destructive testing, to guarantee adherence to exact customer specifications and industry standards. This meticulous attention to detail ensures that our aluminum tooling castings not only meet but often exceed the performance expectations of our clients. Our advanced capabilities allow for the production of castings with intricate geometries and tight tolerances, essential for high-precision tooling.

Applications of Aluminum Tooling Castings

The versatility of aluminum tooling castings makes them indispensable across a wide range of industries. They are extensively used in the automotive sector for creating molds for plastic components, jigs, and fixtures due to their lightweight nature and excellent heat transfer capabilities. In the aerospace industry, they are employed in prototyping and for manufacturing parts where weight reduction is critical. The packaging industry benefits from aluminum tooling for creating blow molds and thermoforming tools, where rapid cooling is essential for high-volume production. Furthermore, consumer goods manufacturers utilize these castings for various molding and forming applications, from intricate electronic enclosures to everyday household items. Aluminum tooling castings are also vital in the production of pattern equipment for other casting processes, demonstrating their fundamental role in the broader manufacturing ecosystem. Their ability to facilitate quick design iterations also makes them ideal for rapid prototyping and product development.

Acquiring this Product from MT Royal: Your Trusted Aluminum Tooling Castings Manufacturer

When it comes to sourcing high-quality aluminum tooling castings, partnering with an experienced and reliable Aluminum Tooling Castings Manufacturer is crucial. MT Royal stands out as a preferred choice, offering a seamless and efficient procurement process. We work closely with our clients from the initial design phase through to final delivery, ensuring that their specific needs are met with precision and expertise. Our dedicated team of engineers and customer service representatives is committed to providing comprehensive support, offering technical guidance and timely updates. MT Royal‘s state-of-the-art facilities and commitment to continuous improvement guarantee that you receive the best possible product, delivered on schedule. Choosing MT Royal means choosing a partner who understands the intricacies of tooling and is dedicated to your success. Our competitive pricing and exceptional quality make us the ideal choice for your tooling investment.

Conclusion

The widespread adoption of aluminum tooling castings underscores their enduring value in modern manufacturing. From accelerating production cycles to reducing operational costs, these versatile components are vital for industries seeking to remain competitive. As a leading Aluminum Tooling Castings Manufacturer, MT Royal is proud to contribute to this evolution, providing innovative and high-performance solutions. Our unwavering commitment to quality, precision, and customer satisfaction ensures that we remain at the forefront of the industry. By choosing MT Royal, businesses are not just acquiring tooling; they are investing in a partnership that fosters efficiency, innovation, and long-term success. The future of manufacturing will undoubtedly continue to rely on the advanced capabilities offered by these essential components.

Reviews

There are no reviews yet.