Choosing the right Crane Parts Casting Manufacturer is crucial for the safety, efficiency, and longevity of your lifting operations. In a demanding industry where precision and durability are paramount, the quality of each component directly impacts performance. MT Royal stands as a leading name in this specialized field, offering high-quality cast parts that meet the rigorous demands of various crane types. Our commitment to excellence ensures that every product contributes to the seamless operation of your equipment, minimizing downtime and maximizing productivity.

Introduction to a Leading Crane Parts Casting Manufacturer

In the complex world of heavy machinery, cranes play an indispensable role in various industries, from construction and shipping to manufacturing and mining. The reliable operation of these machines hinges entirely on the quality and integrity of their components. This is where a dedicated Crane Parts Casting Manufacturer like MT Royal becomes an essential partner. We understand that each cast part, no matter how small, contributes significantly to the overall strength, stability, and safety of a crane. Our extensive experience and advanced manufacturing processes allow us to produce castings that not only meet but often exceed industry standards. At MT Royal, we are committed to supplying parts that ensure your cranes operate at peak performance, providing the dependability you need for critical lifting tasks. Our focus on innovation and quality control makes us a preferred choice for businesses seeking durable and reliable crane components.

Product Introduction: Precision Castings from MT Royal

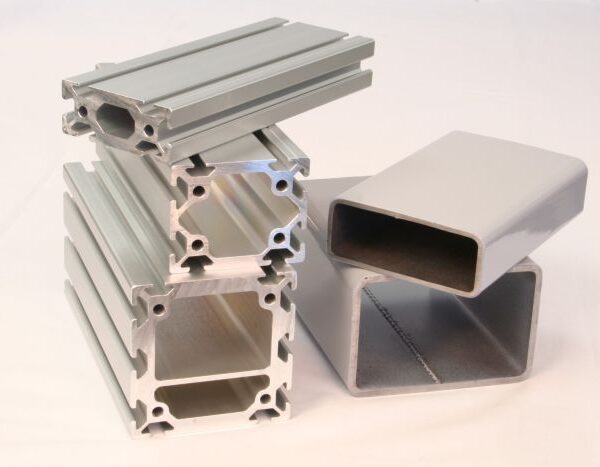

MT Royal specializes in the production of a comprehensive range of cast parts essential for various types of cranes. Our product portfolio includes critical components such as hooks, sheaves, gears, counterweights, and housings, all meticulously crafted to withstand extreme operational stresses. Utilizing advanced casting techniques like sand casting, investment casting, and die casting, we ensure each part exhibits superior strength, wear resistance, and dimensional accuracy. The selection of materials, including various grades of steel, iron, and specialized alloys, is based on the specific application and performance requirements of each component. This careful selection, combined with stringent quality control measures at every stage of production, guarantees that our castings perform reliably under the most challenging conditions. MT Royal’s commitment to precision engineering ensures that every part fits perfectly and functions flawlessly within your crane systems. We pride ourselves on delivering components that enhance the longevity and safety of your heavy machinery.

Advantages of Choosing MT Royal’s Cast Crane Parts

When you select cast crane parts from MT Royal, you are investing in unparalleled quality and reliability. Our components offer significant advantages that translate into better performance and reduced operational costs. Firstly, our parts boast superior durability due to the high-grade materials and advanced heat treatment processes employed, significantly extending the lifespan of your crane. Secondly, the precision engineering of our castings ensures perfect fit and seamless integration, minimizing wear and tear on adjacent components and reducing the likelihood of unexpected failures. Thirdly, our robust manufacturing processes result in parts with excellent resistance to fatigue and corrosion, crucial for operations in harsh environments. Lastly, by choosing MT Royal as your Crane Parts Casting Manufacturer, you benefit from our commitment to strict quality control, ensuring that every part meets the highest industry standards. These advantages collectively contribute to enhanced operational safety, reduced maintenance requirements, and improved overall productivity for your crane fleet.

Product Specifications: Meeting Industry Demands

Our cast crane parts are manufactured to precise specifications, ensuring optimal performance and compatibility with a wide range of crane models. We adhere to international standards such as ASTM, DIN, and JIS, guaranteeing that our products meet global quality benchmarks. Key specifications include material composition, dimensional tolerances, surface finish, and mechanical properties like tensile strength, yield strength, and hardness. For instance, our hooks are typically cast from high-strength carbon steel or alloy steel, designed to withstand immense loads while maintaining structural integrity. Sheaves are engineered with optimal groove profiles to ensure smooth rope movement and minimize wear. Counterweights are produced with specific densities to provide the necessary balance for safe lifting operations. Every product undergoes rigorous testing, including ultrasonic testing, magnetic particle inspection, and radiographic inspection, to detect any internal flaws and ensure structural soundness. This meticulous attention to detail in our product specifications ensures that MT Royal delivers only the most reliable and high-performing crane components.

Applications of MT Royal’s Crane Parts

The cast parts produced by MT Royal are integral to the functionality of a diverse range of crane types across numerous industries. Our components are essential for overhead cranes, commonly found in factories and warehouses for material handling, providing the necessary strength for repetitive lifting tasks. For gantry cranes, frequently used in shipyards and large construction sites, our robust castings ensure stable and safe movement of heavy loads over wide spans. Mobile cranes, vital for construction, infrastructure projects, and emergency recovery, rely on our durable cast parts for their operational flexibility and strength on varied terrains. Furthermore, our components are crucial for tower cranes, which dominate urban construction landscapes, requiring parts that can withstand immense heights and constant stress. Industries benefiting from our products include construction, marine and port operations, manufacturing, mining, and energy. Regardless of the application, MT Royal’s cast crane parts provide the critical support and reliability needed for efficient and safe lifting operations.

Purchasing Your Crane Parts from MT Royal

Acquiring high-quality crane parts is a strategic decision for any business involved in lifting operations. MT Royal simplifies this process by offering a streamlined and customer-focused purchasing experience. As a dedicated Crane Parts Casting Manufacturer, we ensure that our clients receive not only superior products but also exceptional service. Our sales team is highly knowledgeable and ready to assist you in selecting the right components for your specific crane models and operational needs. We provide detailed product information, technical specifications, and transparent pricing to help you make informed decisions. Furthermore, MT Royal is committed to efficient logistics and timely delivery, ensuring that your parts arrive when and where you need them, minimizing potential downtime. Our strong commitment to customer satisfaction and product excellence makes MT Royal the ideal partner for all your crane parts requirements. Choosing us means choosing reliability, quality, and a commitment to your operational success.

Conclusion: Your Trusted Crane Parts Casting Manufacturer

In summary, the operational integrity and safety of any crane heavily depend on the quality of its individual components. As a leading Crane Parts Casting Manufacturer, MT Royal is dedicated to providing superior cast parts that meet the highest standards of durability, precision, and performance. Our extensive product range, advanced manufacturing processes, and rigorous quality control measures ensure that every component contributes to the seamless and reliable operation of your cranes. We are proud to be a trusted partner for businesses across various industries, supplying essential parts that enhance efficiency, reduce maintenance costs, and ensure the safety of critical lifting operations. Choosing MT Royal means investing in quality that stands the test of time and demanding conditions. We invite you to experience the difference that our commitment to excellence can make for your operations.

Reviews

There are no reviews yet.