It begins with an exploration of what makes a reliable Filter Paper Pulp Supplier. This journey delves into the core qualities of high-grade filter paper pulp, a fundamental component in countless industrial and scientific applications. Understanding its properties and diverse uses is crucial for anyone seeking optimal performance in filtration processes. Choosing the right supplier is paramount. It directly impacts the efficiency and success of end-products.

Unveiling the World of Filter Paper Pulp

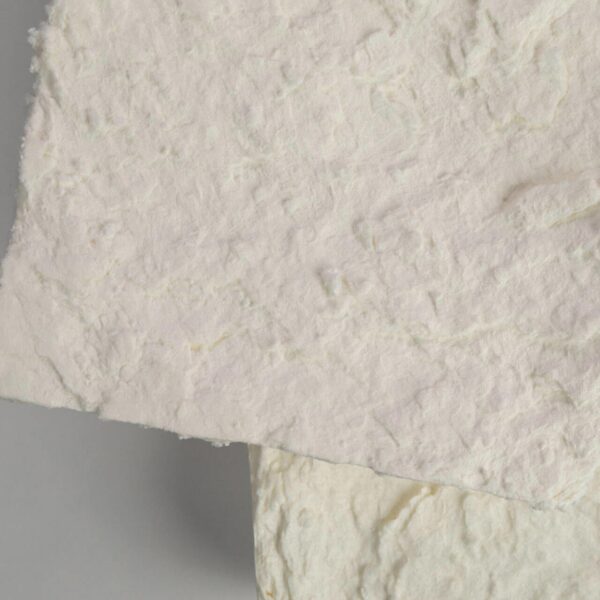

Filter paper pulp is more than just processed cellulose fibers. It is a carefully engineered material. Its primary function is to separate solids from liquids or gases. This is achieved through a network of microscopic pores. These pores allow fluids to pass while trapping particulate matter. The quality of the pulp directly influences filtration efficiency. A superior pulp ensures consistent pore size. It also guarantees mechanical strength. This prevents breakage during use. High-purity pulp is essential. Contaminants can compromise filtration results.

What is Filter Paper Pulp?

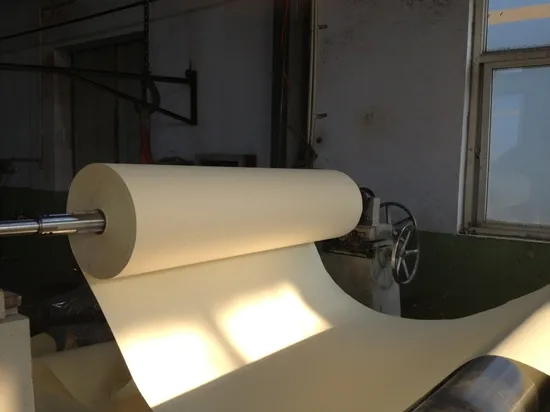

Filter paper pulp is derived from high-quality cellulose. Wood pulp is often the source. It undergoes extensive processing. This process removes impurities. It also refines fiber size. The goal is to create a uniform material. This material must have excellent filtration characteristics. Different types of pulp exist. Each is suited for specific applications. For example, some pulps are acid-washed. This removes metal ions. Other pulps are bleached. This enhances purity. The manufacturing process is critical. It determines the final product’s performance.

Advantages of Quality Filter Paper Pulp

Investing in high-quality filter paper pulp offers numerous benefits. These advantages extend across various industries. They impact both efficiency and cost-effectiveness. A reliable Filter Paper Pulp Supplier ensures these benefits are consistently delivered.

- Superior Filtration Efficiency: High-grade pulp captures even fine particles. This leads to cleaner filtrates.

- Enhanced Flow Rates: Optimized fiber structure allows for faster filtration. This improves process speed.

- Excellent Wet Strength: Quality pulp maintains integrity when wet. It resists tearing and bursting.

- Chemical Compatibility: Certain pulps are designed for specific chemical environments. This prevents degradation.

- Low Extractables: Pure pulp minimizes the leaching of impurities. This ensures product purity.

- Cost-Effectiveness: Efficient filtration reduces the need for multiple passes. This saves time and resources.

Diverse Applications of Filter Paper Pulp

Filter paper pulp is an indispensable material. Its applications span a vast array of sectors. From laboratory analysis to large-scale industrial processes, its versatility is evident.

Key Industrial Uses

In industrial settings, filter paper pulp plays a vital role. It is used in countless manufacturing processes. It ensures product quality and process efficiency. For example, in the food and beverage industry, it purifies liquids. This includes juices, oils, and spirits. In pharmaceuticals, it is critical for sterile filtration. It removes contaminants from drug formulations. The chemical industry uses it for separating solids from chemical solutions. This includes acids and bases. The oil and gas sector employs it for refining crude oil. It removes impurities from lubricants. Environmental applications also rely on it. It filters wastewater and air. This ensures compliance with regulations.

Laboratory and Scientific Applications

Laboratories heavily depend on filter paper pulp. It is fundamental for various analytical techniques. In microbiology, it filters culture media. This prepares samples for analysis. In analytical chemistry, it separates precipitates. This allows for accurate quantitative analysis. It is used in chromatography. This technique separates mixtures into their components. Research and development labs use it daily. It aids in countless experiments. The precision offered by quality pulp is crucial here. It ensures reliable and reproducible results. MT Royal understands these demanding requirements.

Why Choose MT Royal as Your Filter Paper Pulp Supplier?

Selecting the right Filter Paper Pulp Supplier is a critical decision. MT Royal stands out in the market. We offer superior products and unparalleled service. Our commitment to quality is unwavering.

We source only the finest raw materials. Our manufacturing processes are state-of-the-art. This ensures consistent product excellence. We adhere to stringent quality control measures. Every batch of pulp undergoes rigorous testing. This guarantees it meets the highest standards. Our product range is extensive. We offer various grades and types of filter paper pulp. This caters to diverse industry needs.

Our technical support team is highly knowledgeable. They provide expert guidance. They assist clients in choosing the optimal pulp for their applications. We prioritize customer satisfaction. Our delivery is timely and reliable. We understand the importance of uninterrupted supply. We build long-term relationships with our clients. Our reputation is built on trust and performance. Choosing MT Royal means partnering with a leader. We are dedicated to your success.

Conclusion

The importance of high-quality filter paper pulp cannot be overstated. It is a cornerstone for efficient and reliable filtration. From industrial applications to scientific research, its role is pivotal. A dependable Filter Paper Pulp Supplier like MT Royal is essential. We provide the quality and consistency that your processes demand. Partnering with us ensures access to superior products. It guarantees expert support. This helps your operations thrive.

Reviews

There are no reviews yet.