For industries seeking innovative and lightweight material solutions, foaming plastic raw material supplier plays a crucial role. These materials offer unique properties. They combine excellent insulation with a high strength-to-weight ratio. This makes them indispensable for a wide range of applications. From construction to automotive, their versatility is unmatched. MT Royal stands as a leading provider in this specialized market. We ensure our clients receive top-quality products. Our commitment to excellence supports your manufacturing needs. We help you achieve superior product performance.

Introduction to Foaming Plastic Raw Materials

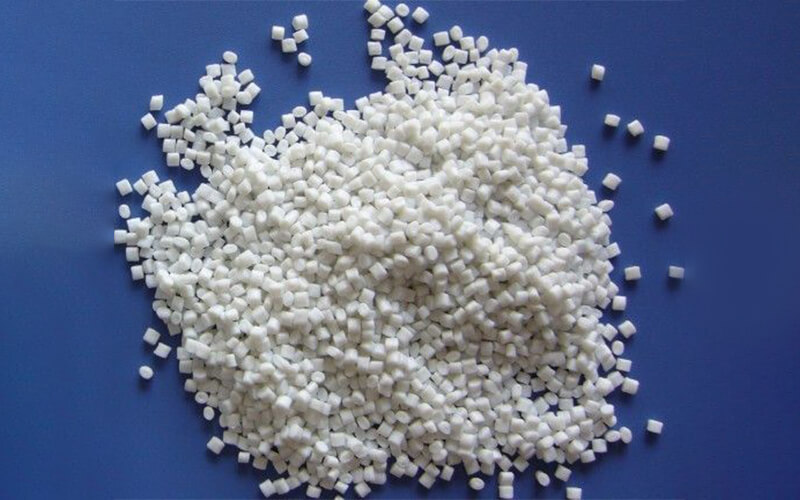

Foaming plastic raw materials are polymers designed to incorporate gas bubbles during processing. This creates a cellular structure. This structure significantly reduces the material’s density. It also enhances its thermal and acoustic insulation properties. The process involves various methods. These include chemical blowing agents or physical injection of gases. The result is a lightweight yet robust material. This offers numerous advantages over traditional solids. Different types of polymers can be foamed. These include polyethylene, polypropylene, and PVC. Each offers distinct characteristics. These cater to specific industrial demands. Choosing the right foaming plastic raw material supplier is vital. It impacts the final product’s quality and performance.

Products Overview: The Versatility of Foaming Plastics

Foaming plastic raw materials are available in diverse forms. These include pellets, powders, and liquids. Their end properties vary based on the polymer type and foaming process. For instance, expanded polystyrene (EPS) is known for its excellent insulation. It is widely used in packaging and construction. Expanded polypropylene (EPP) offers superior impact absorption. This makes it ideal for automotive components. Polyurethane foams provide versatile solutions. They are used in furniture, insulation, and even footwear. The ability to customize cell structure and density is a key benefit. This allows manufacturers to tailor materials precisely. They can meet specific application requirements. Understanding these variations is essential. It helps in selecting the optimal material. MT Royal offers a comprehensive range. We ensure you find the perfect fit for your projects.

Advantages of Foaming Plastic Raw Materials

The benefits of using foaming plastic raw materials are numerous.

- Lightweight: The cellular structure drastically reduces weight. This leads to lower transportation costs. It also improves fuel efficiency in vehicles.

- Insulation: Entrapped gas bubbles provide excellent thermal and acoustic insulation. This is crucial for energy efficiency in buildings and appliances.

- Impact Absorption: Foamed plastics can absorb significant impact energy. They protect products during transit. They also enhance safety in automotive applications.

- Cost-Effectiveness: Reduced material usage due to lower density translates to cost savings. This is particularly true in large-volume production.

- Design Flexibility: The ability to mold foamed plastics into complex shapes is a major advantage. This enables innovative product designs.

These advantages highlight why demand for these materials is growing. A reliable foaming plastic raw material supplier like MT Royal is indispensable. We provide consistent quality.

Applications of Foaming Plastic Raw Materials

Foaming plastic raw materials find extensive use across various industries.

- Automotive: They are used in car interiors for sound deadening. They also feature in bumpers and seating for weight reduction and safety.

- Construction: Insulation boards, pipe insulation, and structural foams are common applications. They improve energy efficiency in buildings.

- Packaging: Protective packaging for electronics and fragile goods benefits from their cushioning properties.

- Sporting Goods: Helmets, protective gear, and flotation devices utilize foamed plastics for their impact absorption and buoyancy.

- Furniture: Upholstery, cushioning, and structural components often incorporate foamed materials for comfort and lightness.

- Medical: Orthotics, prosthetics, and various disposable medical devices use these specialized materials.

The broad range of applications demonstrates their versatility. It underscores their importance in modern manufacturing.

Why Purchase from MT Royal as Your Foaming Plastic Raw Material Supplier?

Choosing the right partner is paramount. MT Royal is a trusted leader in the supply of foaming plastic raw materials. Our commitment to quality is unwavering. We source only the finest polymers. Our products meet stringent international standards. We offer a diverse product portfolio. This ensures we can meet varied industrial demands. Our technical support team is highly knowledgeable. They provide expert guidance. They help you select the ideal material for your specific application. We prioritize customer satisfaction. We ensure timely delivery and competitive pricing. Our global logistics network is robust. This guarantees efficient supply chain management. Partnering with MT Royal means gaining access to premium materials. It also means benefiting from exceptional service. We help you innovate and excel in your industry.

Conclusion

Foaming plastic raw materials are transforming industries worldwide. They offer an unparalleled combination of properties. Their lightweight nature, excellent insulation, and superior impact absorption make them invaluable. From enhancing energy efficiency to improving product safety, their impact is significant. As a premier foaming plastic raw material supplier, MT Royal is dedicated to supporting your success. We provide top-tier materials. We back them with expert knowledge and reliable service. Embrace the future of material science with MT Royal. We empower your innovations.

Reviews

There are no reviews yet.