In the demanding world of mining, aggregates, and recycling, efficient material separation is paramount. From the initial stages of processing to final product preparation, the right equipment makes all the difference. Among these essential machines, grizzly screens stand out as robust and reliable primary scalping devices. They are designed to handle large, often abrasive, materials, effectively protecting downstream crushers and optimizing overall operational flow. When seeking such critical equipment, partnering with a reputable Grizzly Screens Manufacturer like MT Royal is crucial for ensuring quality, durability, and performance. MT Royal has established itself as a leader in providing high-quality screening solutions that meet the rigorous demands of various industrial applications. Their commitment to innovation and customer satisfaction sets them apart in the market, offering solutions that genuinely enhance productivity and efficiency for their clients.

Introducing the Core of Efficient Material Processing: Grizzly Screens

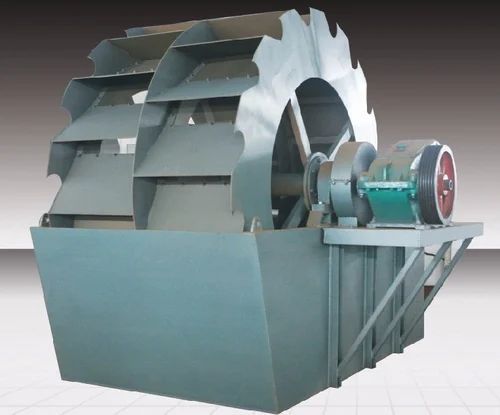

Grizzly screens are a foundational component in many material processing lines, acting as the first line of defense against oversized and unwanted materials. Their primary function is to scalp, or pre-screen, raw feed, allowing smaller particles to pass through while directing larger ones to subsequent crushing stages. This not only improves the efficiency of crushers by preventing them from being fed oversized material but also significantly reduces wear and tear on these expensive machines. The design typically involves a series of parallel bars or rods, spaced to create specific apertures that dictate the size of material allowed to pass. A Grizzly Screens Manufacturer like MT Royal understands the intricate balance required between robust construction and precise engineering to deliver screens that perform consistently under extreme conditions. Their expertise ensures that each screen is built to withstand the harshest environments, providing long-term reliability and reducing maintenance requirements for operators.

Advantages of Superior Grizzly Screens

Investing in high-quality grizzly screens offers a multitude of advantages that directly impact operational efficiency and profitability. Firstly, their ability to pre-screen material significantly reduces the load on primary crushers, leading to decreased energy consumption and extended lifespan for these critical pieces of equipment. This translates into substantial cost savings over time. Secondly, by removing fine materials early in the process, the overall throughput of the crushing circuit can be optimized, increasing productivity. Thirdly, the robust construction of well-engineered grizzly screens minimizes downtime, ensuring continuous operation even in challenging environments. A reliable Grizzly Screens Manufacturer focuses on using high-strength materials and advanced fabrication techniques, resulting in screens that resist abrasion and impact, common challenges in material processing. MT Royal prides itself on manufacturing grizzly screens that excel in durability and performance, delivering tangible benefits to their clients through reduced operational costs and improved material processing efficiency.

Product Specifications to Consider

When evaluating grizzly screens, several key specifications determine their suitability for specific applications. The material of construction is paramount, with manganese steel or other highly abrasion-resistant alloys often preferred for their longevity. The bar spacing, or aperture size, is critical for achieving the desired separation, influencing the size of material that passes through. Length and width dimensions of the screen directly impact its capacity and ability to handle varying volumes of feed. Static grizzlies are simple, cost-effective solutions for basic scalping, while vibrating grizzlies offer enhanced efficiency and throughput, particularly with sticky or damp materials. The power unit and vibration mechanism are crucial considerations for vibrating models, ensuring optimal performance and reliability. A reputable Grizzly Screens Manufacturer will offer a range of configurations and customization options to meet unique project requirements, ensuring that each client receives a solution perfectly tailored to their needs.

Diverse Applications for Grizzly Screens

Grizzly screens are incredibly versatile, finding applications across a broad spectrum of industries where bulk material handling and separation are essential. In mining operations, they are indispensable for primary scalping of ore and waste rock, ensuring that only appropriately sized material enters the crushing circuit. This protects crushers from damage and optimizes downstream processing. Quarries utilize them to pre-screen aggregates, separating large boulders from sand and gravel, which can then be further processed into various construction materials. In the recycling industry, grizzly screens are used to remove large debris and contaminants from mixed waste streams, preparing the material for more refined sorting and recycling processes. Their robust nature makes them ideal for handling diverse materials, from demolition waste to industrial by-products. The ability of a Grizzly Screens Manufacturer like MT Royal to provide customized solutions means their products can be effectively integrated into various operational setups, from large-scale industrial plants to smaller, specialized processing facilities, proving their adaptability and critical role in material processing.

Acquiring This Essential Product from MT Royal

For businesses seeking to enhance their material processing capabilities, acquiring grizzly screens from a trusted supplier is a critical decision. MT Royal stands as a premier Grizzly Screens Manufacturer, renowned for its commitment to quality, engineering excellence, and customer service. Their extensive range of grizzly screens, including both static and vibrating models, are designed to meet the diverse needs of clients in mining, aggregates, and recycling. When you choose MT Royal, you are not just purchasing a piece of equipment; you are investing in a robust, reliable solution backed by years of industry expertise. Their team of specialists works closely with clients to understand their specific requirements, offering tailored advice and ensuring that the selected grizzly screen perfectly integrates into existing operations. MT Royal’s dedication to after-sales support further ensures long-term performance and peace of mind for their customers.

The Future of Material Processing with a Leading Grizzly Screens Manufacturer

The efficiency and profitability of material processing operations heavily depend on the quality and performance of their core equipment. Grizzly screens, as primary scalping devices, play a pivotal role in this ecosystem, safeguarding downstream machinery and optimizing throughput. As a leading Grizzly Screens Manufacturer, MT Royal continues to innovate, providing advanced and durable screening solutions that meet the evolving demands of various industries. Their commitment to engineering excellence, use of high-grade materials, and focus on customer satisfaction ensure that businesses can rely on MT Royal for superior performance and long-term value. Partnering with MT Royal means investing in the future of your material processing operations, ensuring efficiency, reliability, and sustained productivity.

Reviews

There are no reviews yet.