In the demanding world of industrial machinery, the integrity and performance of every component are paramount. Gears, in particular, serve as the backbone of countless mechanical systems, facilitating power transmission and precise motion. Among the various types, hardened steel gears stand out for their exceptional durability and resistance to wear, making them indispensable in high-stress applications. When seeking such critical components, partnering with a reliable Hardened Steel Gears Supplier is crucial. MT Royal has established itself as a leading provider in this specialized field, consistently delivering products that meet the stringent requirements of modern industry. Our dedication to quality and customer satisfaction ensures that businesses receive not just gears, but solutions that enhance operational efficiency and longevity.

Product Introduction: Understanding Hardened Steel Gears

Hardened steel gears are not merely components; they are engineered solutions designed to withstand the most arduous conditions. Unlike standard gears, these are subjected to specialized heat treatments, such as carburizing, nitriding, or induction hardening. These processes significantly increase the surface hardness of the steel while maintaining a tough, ductile core. This unique combination provides superior resistance to abrasion, fatigue, and impact, ensuring a longer operational lifespan and fewer breakdowns. MT Royal, as a prominent player in the “Gears & Gearboxes” category, understands the intricate engineering behind these parts. We ensure that every gear supplied adheres to the highest metallurgical standards, guaranteeing optimal performance in diverse industrial settings.

Advantages of Hardened Steel Gears

The benefits of utilizing hardened steel gears are manifold, directly impacting the efficiency, reliability, and cost-effectiveness of industrial operations. Firstly, their enhanced durability translates into extended service life, significantly reducing the frequency of replacements and associated maintenance costs. This robustness makes them ideal for applications involving heavy loads, high speeds, and continuous operation. Secondly, the superior wear resistance of hardened steel minimizes material loss, maintaining precise tooth profiles and ensuring consistent power transmission over time. This reduces backlash and improves the overall efficiency of mechanical systems. Furthermore, their high strength-to-weight ratio allows for more compact gearbox designs without compromising performance. MT Royal’s hardened steel gears contribute to greater uptime and reduced operational expenditures for our clients.

Product Specifications

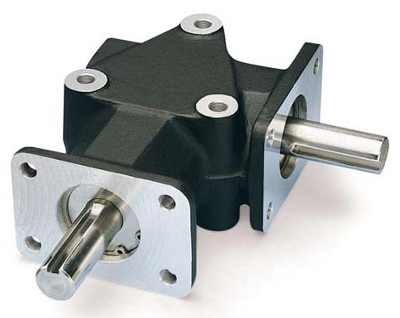

When considering hardened steel gears, specific technical specifications are crucial for ensuring compatibility and optimal performance. Our range of hardened steel gears, offered by MT Royal, typically features materials such as alloy steels (e.g., 4140, 4340, 8620) known for their excellent response to heat treatment. The hardness level is often measured in Rockwell (HRC), with values typically ranging from 55 HRC to 62 HRC for the hardened surface. Gears can be supplied in various types, including spur gears, helical gears, bevel gears, worm gears, and rack and pinion systems, each designed for specific applications. Precision grinding after hardening is often employed to achieve tight tolerances and superior surface finish, which minimizes noise and vibration during operation. MT Royal provides detailed specifications for each product, assisting clients in selecting the perfect gear for their unique industrial requirements. Our engineering team is always ready to consult on custom solutions, ensuring that every specification perfectly aligns with the client’s needs.

Applications of Hardened Steel Gears

The robustness and reliability of hardened steel gears make them indispensable across a vast spectrum of industrial applications. They are critical components in heavy machinery such as mining equipment, where they endure extreme loads and abrasive environments. In the automotive industry, they are found in transmissions and differentials, providing the necessary strength for powertrain systems. Construction machinery, including excavators and cranes, relies on these gears for robust power transfer. Furthermore, they are extensively used in wind turbines, agricultural equipment, robotics, and machine tools, where precision, durability, and resistance to fatigue are paramount. The versatility of hardened steel gears ensures their presence in nearly any industry demanding high-performance mechanical drive systems. MT Royal’s extensive inventory caters to these diverse applications, ensuring that industries worldwide have access to the highest quality components for their critical operations.

Purchasing Hardened Steel Gears from MT Royal

Choosing the right Hardened Steel Gears Supplier is a decision that impacts the long-term performance and reliability of your machinery. MT Royal prides itself on being a premier source for high-quality hardened steel gears. Our commitment extends beyond just supplying products; we offer comprehensive support, from initial consultation to after-sales service. We understand the unique demands of various industries and work closely with our clients to provide tailored solutions. Our streamlined ordering process, coupled with efficient logistics, ensures timely delivery of products, minimizing downtime for your operations. By partnering with MT Royal, you gain access to a vast selection of durable and precision-engineered gears, backed by a team of experts dedicated to your success. Our reputation for excellence in the “Gears & Gearboxes” category is built on consistent quality, competitive pricing, and unparalleled customer service.

Final Remarks

In conclusion, the significance of hardened steel gears in modern industrial landscapes cannot be overstated. Their unparalleled strength, wear resistance, and longevity are vital for the efficient and reliable operation of countless machines. As a leading Hardened Steel Gears Supplier, MT Royal remains dedicated to providing top-tier products that meet and exceed industry expectations. Our extensive range of gears, coupled with our unwavering commitment to quality and customer satisfaction, positions us as the preferred partner for businesses globally. Whether you require standard components or custom-engineered solutions, MT Royal is equipped to deliver the high-performance gears your operations demand. We are proud to contribute to the efficiency and durability of industrial systems worldwide.

Reviews

There are no reviews yet.