Finding a reliable Helical Gears Supplier is crucial for various industries. MT Royal stands as a premier provider, offering high-quality helical gears designed for superior performance. Our commitment to precision engineering ensures that your machinery operates smoothly and efficiently.

Introduction: Your Premier Helical Gears Supplier

In the world of mechanical power transmission, the choice of components significantly impacts system efficiency and longevity. For businesses seeking precision and durability, identifying a trustworthy Helical Gears Supplier is paramount. MT Royal has established itself as a leading name in this specialized field. We provide a comprehensive range of helical gears. Our products meet the exacting standards of modern industrial applications. We are dedicated to ensuring your machinery operates with optimal performance and minimal noise.

Helical Gears: Product Introduction and Specifications

Helical Gears: Product Introduction and Specifications

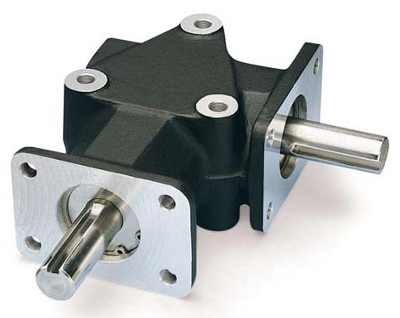

Helical gears are a type of cylindrical gear. Their teeth are cut at an angle to the gear’s axis. This angled design differentiates them from spur gears, which have teeth parallel to the axis. This unique tooth alignment offers several advantages. Helical gears are widely used in various industries. They are known for their smooth and quiet operation.

What are Helical Gears?

Helical gears transmit power between parallel or non-parallel shafts. The angled teeth engage more gradually than straight teeth. This gradual engagement allows for smoother power transfer. It also reduces shock and vibration. Helical gears can be manufactured in both right-hand and left-hand helix angles. Paired helical gears typically have opposite helix angles. This ensures proper meshing.

Key Specifications of Helical Gears

- Helix Angle: This is the angle at which the teeth are cut relative to the gear’s axis. It impacts the thrust load generated.

- Module/Pitch: Determines the size of the gear teeth.

- Number of Teeth: Influences the gear ratio and rotational speed.

- Material: Common materials include steel, alloy steel, and sometimes plastics for lighter applications.

- Heat Treatment: Processes like hardening and tempering enhance durability.

- Accuracy Grade: Refers to the precision of the gear’s manufacturing, impacting its performance.

Product Features and Their Advantages

The distinctive design of helical gears offers several key features. These features translate into significant operational advantages. Partnering with a reliable Helical Gears Supplier like MT Royal guarantees access to these benefits. Our gears are engineered for superior performance.

Smooth and Quiet Operation

The angled teeth of helical gears engage gradually. This gradual contact reduces impact and minimizes noise. It leads to a much smoother operation compared to spur gears. This feature is crucial in applications requiring low noise levels. It also reduces wear and tear on components.

Higher Load Carrying Capacity

Helical gears have a larger contact ratio than spur gears. More teeth are in contact at any given time. This distributes the load over a greater area. Consequently, helical gears can handle higher loads. They are more durable under demanding conditions. This enhances the overall lifespan of the gear system.

Reduced Vibration and Shock

The continuous tooth contact of helical gears results in less vibration. It also minimizes shock loads. This provides a more stable power transmission. Reduced vibration contributes to less noise. It also lowers the stress on connected machinery.

Suitable for High Speeds

Due to their smooth engagement, helical gears are ideal for high-speed applications. They can transmit power efficiently without excessive noise or vibration. This makes them a preferred choice in high-performance machinery.

Axial Thrust Capabilities

While providing advantages, the helical design creates an axial thrust force. This force pushes the gear along its axis. This requires thrust bearings to manage. However, this characteristic can also be utilized in specific designs. Double helical or herringbone gears eliminate axial thrust.

Applications of Helical Gears Across Industries

The versatility and superior performance of helical gears make them indispensable. They are used in a broad spectrum of industrial applications. As a leading Helical Gears Supplier, MT Royal serves diverse sectors. Our products contribute to the efficiency of many different machines.

Automotive Industry

- Transmissions: Widely used in manual and automatic transmissions. Their smooth operation ensures quiet shifts.

- Differentials: Found in vehicle differentials for power distribution.

Industrial Machinery

- Machine Tools: Employed in various machine tools for precise movements.

- Pumps: Used in high-pressure pumps for efficient fluid transfer.

- Compressors: Critical components in air and gas compressors.

Power Generation

- Turbines: Used in wind turbines and other power generation systems. They ensure reliable power transfer.

- Gearboxes: Essential for reducing rotational speed in power plants.

Material Handling Equipment

- Conveyors: Found in conveyor systems for smooth and consistent movement.

- Cranes: Used in crane mechanisms for lifting heavy loads.

Other Applications

- Printing Presses: Provide smooth and precise paper feeding.

- Textile Machinery: Used in textile manufacturing for various processes.

- Robotics: Enable precise and quiet movement in robotic systems.

MT Royal: Your Best Helical Gears Supplier

Selecting the right Helical Gears Supplier is a critical decision. It directly impacts your operational efficiency and product quality. MT Royal is committed to being your top choice. We deliver excellence in every aspect of our service and product offering.

Uncompromising Quality Standards

At MT Royal, quality is our highest priority. We manufacture helical gears using premium materials. Our production processes adhere to strict international standards. Every gear undergoes rigorous inspection. This ensures superior performance and longevity. You can trust our products for demanding applications.

Advanced Manufacturing Capabilities

We utilize state-of-the-art machinery and advanced manufacturing techniques. Our facilities are equipped for precision machining and heat treatment. This allows us to produce helical gears with tight tolerances. Our capabilities ensure consistent quality and high accuracy.

Extensive Range and Customization

We offer a wide selection of standard helical gears. We also provide custom solutions to meet specific requirements. Our engineering team works closely with clients. We design and produce gears tailored to unique applications. This flexibility sets us apart.

Reliable and Timely Delivery

We understand the importance of timely supply. MT Royal has a streamlined logistics system. This ensures prompt and efficient delivery of your orders. We minimize lead times. Our reliable service helps you maintain continuous production.

Expert Technical Support

Our team of experienced engineers provides comprehensive technical support. We assist with product selection and application queries. We offer expert advice to optimize your gear solutions. Our commitment extends beyond just supplying products.

Competitive Pricing

MT Royal offers highly competitive pricing. We provide excellent value without compromising on quality. We believe in building long-term partnerships. Our pricing strategy supports your business objectives.

Conclusion: Partner with MT Royal for Superior Helical Gears

In summary, choosing a reliable Helical Gears Supplier is fundamental for operational success. MT Royal stands as a testament to quality, precision, and customer satisfaction. Our extensive range of high-performance helical gears is designed to meet the most demanding industrial needs. Partner with MT Royal for unparalleled product quality, expert support, and a dependable supply chain. We are ready to be your trusted supplier for all your helical gear requirements.

Helical Gears: Product Introduction and Specifications

Helical Gears: Product Introduction and Specifications

Reviews

There are no reviews yet.