The global beverage industry is a dynamic and highly competitive market where product quality and packaging integrity are paramount. For manufacturers of carbonated drinks, selecting the right raw materials for bottles is a critical decision that directly impacts the final product’s quality, shelf life, and consumer appeal. Among the various options available, Indorama IV 0.86 PET Chips have emerged as a preferred choice, and locating a reliable Indorama IV 0.86 PET Chips for Carbonated Bottles supplier is essential for any business aiming for excellence. This article delves into the features, benefits, and applications of this specialized plastic raw material, highlighting why a partnership with a leading supplier like MT Royal is a smart business move.

Introduction to the Product

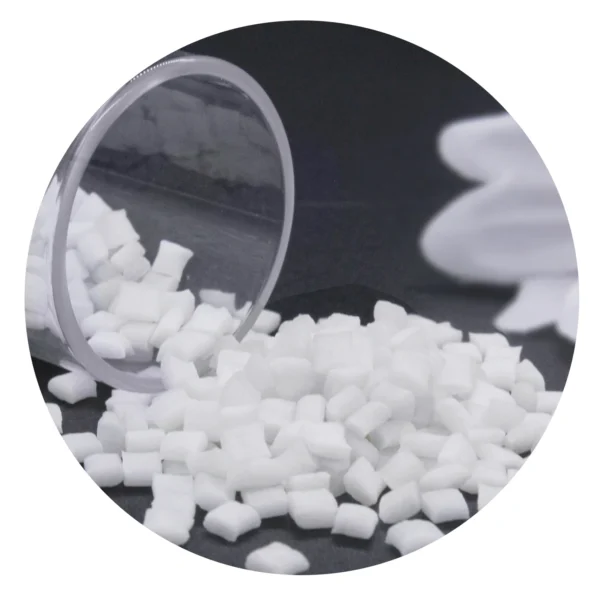

Indorama IV 0.86 PET Chips, also known as polyethylene terephthalate chips, are a high-viscosity polymer specifically designed for blow molding applications. This material is widely used in the production of bottles for carbonated soft drinks, sparkling water, and other pressure-sensitive beverages. The designation “IV 0.86” refers to the intrinsic viscosity of the polymer, a key metric that indicates its molecular weight and suitability for specific applications. A higher intrinsic viscosity (IV) like 0.86 signifies greater molecular chain length, which translates into enhanced strength, improved gas barrier properties, and superior stress resistance—all of which are crucial for bottles containing pressurized liquids. Sourced from a renowned manufacturer like Indorama, these chips guarantee consistency and premium quality.

Advantages of Indorama IV 0.86 PET Chips

The selection of Indorama IV 0.86 PET Chips offers several compelling advantages for beverage manufacturers. The most significant benefit is their exceptional clarity and transparency. This allows consumers to clearly see the product, which is a major factor in purchasing decisions. Another key advantage is their excellent gas barrier properties. Carbonated beverages rely on dissolved carbon dioxide to create their signature effervescence, and any loss of this gas can lead to a “flat” product. These PET chips are highly effective at preventing carbon dioxide from escaping, thereby extending the shelf life and maintaining product quality. Furthermore, the material’s high strength and durability make the bottles resistant to impact and stress cracking, reducing product loss and ensuring safe handling.

Key Specifications of the Product

Understanding the technical specifications of Indorama IV 0.86 PET Chips is vital for their correct application. The intrinsic viscosity of 0.86 dl/g is a standout feature, ensuring the polymer has the necessary strength for pressurized bottles. Other important specifications include low acetaldehyde (AA) content, which prevents any off-taste or odor in the bottled liquid. The material also boasts a narrow molecular weight distribution, which leads to uniform processing and consistent product quality during the manufacturing process. These chips are supplied in a pelletized form, making them easy to handle, transport, and feed into the injection molding or blow molding machines.

Applications of the Product

While the primary use of Indorama IV 0.86 PET Chips is in the production of bottles for carbonated beverages, their high quality and specific properties make them suitable for a variety of other applications. These include bottles for still water, edible oils, sauces, and even some non-food applications like household cleaning products. However, their superior performance in withstanding internal pressure makes them the go-to choice for soft drink manufacturers. The versatility and reliability of this plastic raw material make it a cornerstone of the packaging industry, with demand remaining consistently high.

Why Choose a Premier Indorama IV 0.86 PET Chips for Carbonated Bottles Supplier?

Partnering with a reputable and experienced supplier is as important as the quality of the product itself. A reliable supplier, such as MT Royal, ensures a consistent and uninterrupted supply chain. They manage logistics, quality control, and timely delivery, allowing manufacturers to focus on their core business operations. MT Royal has established itself as a leader in the distribution of plastic raw materials, building a reputation for reliability, customer service, and competitive pricing. Their deep understanding of the market and commitment to quality make them an ideal partner for businesses looking to secure their supply of high-grade PET chips.

Sourcing from MT Royal: Your Trusted Supplier

MT Royal is a prominent name in the global market for plastic raw materials, and its offering of Indorama IV 0.86 PET Chips is a testament to its commitment to quality. By choosing MT Royal, you gain access to a reliable supply of premium materials, backed by expert support and a strong logistical network. They ensure that every batch meets the highest quality standards, providing manufacturers with peace of mind. Their efficient delivery system and customer-centric approach make the procurement process smooth and hassle-free. This partnership allows you to maintain consistent production schedules and deliver top-quality products to your customers.

Final Thoughts on the Indorama IV 0.86 PET Chips for Carbonated Bottles Supplier

In a market where competition is fierce and quality is king, securing a steady supply of high-quality raw materials is non-negotiable. The Indorama IV 0.86 PET Chips for Carbonated Bottles supplier plays a crucial role in the success of any carbonated beverage company. The unique properties of these chips, including their high strength, clarity, and excellent gas barrier, make them a superior choice for bottling applications. Partnering with a reliable company like MT Royal is essential for maintaining production efficiency and ensuring the highest product quality. The strategic importance of selecting the right material and the right partner cannot be overstated. By focusing on these key aspects, businesses can ensure their long-term success and market leadership. The synergy between a premium product like Indorama PET chips and a reliable supplier like MT Royal creates a formidable advantage in a demanding industry.

Reviews

There are no reviews yet.