The demand for high-quality packaging materials continues to grow. Specifically, the beverage industry requires exceptional performance from its plastic components. When seeking a reliable JBF High IV PET Chips for carbonated bottles supplier, look no further than MT Royal. We understand the critical role these chips play in ensuring the safety, clarity, and shelf life of your carbonated beverages. This article explores the benefits and applications of JBF High IV PET Chips, highlighting why MT Royal is your ideal partner.

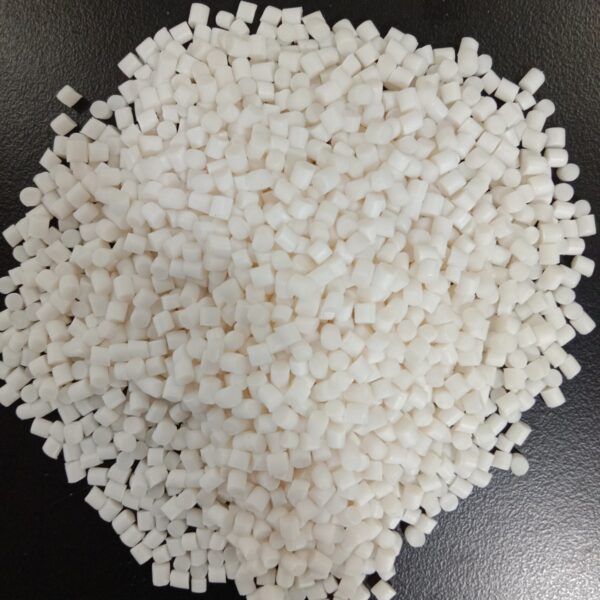

Introduction to JBF High IV PET Chips for Carbonated Bottles

Polyethylene terephthalate (PET) is a widely recognized polymer. It is a preferred material for packaging due to its unique properties. High IV PET chips are crucial for manufacturing carbonated bottles. They offer superior barrier properties and mechanical strength. These characteristics are essential for maintaining fizz and product integrity. Choosing the right JBF High IV PET Chips for carbonated bottles supplier is paramount. It ensures your final product meets the highest standards.

Product Introduction and Specifications

JBF High IV PET Chips are specifically engineered. They are designed for blow molding applications. These applications include the production of carbonated beverage bottles. The “IV” in High IV stands for Intrinsic Viscosity. A higher IV indicates a longer polymer chain. This directly translates to increased strength and rigidity. These chips are manufactured with precision. They meet stringent quality controls. This ensures consistent performance.

Key Features and Their Advantages

JBF High IV PET Chips offer numerous advantages. These benefits make them the top choice for bottlers.

- Exceptional Clarity: The chips produce highly transparent bottles. This enhances product visibility. Consumers prefer clear packaging.

- Superior Barrier Properties: They effectively prevent gas permeation. This keeps carbonated beverages fizzy for longer periods.

- Excellent Mechanical Strength: Bottles made from these chips resist bursting. They withstand internal pressure from carbonation.

- High Purity: The chips are free from contaminants. This ensures no impact on beverage taste or quality.

- Low Acetaldehyde (AA) Content: Lower AA levels are crucial. They prevent off-flavors in sensitive beverages.

- Good Processability: These chips offer consistent melt flow. This allows for efficient bottle production. Reduced waste is also a benefit.

- Recyclability: PET is a fully recyclable material. This supports sustainable packaging initiatives. It aligns with environmental goals.

Applications of JBF High IV PET Chips

The primary application for JBF High IV PET Chips is clear. They are used in the production of bottles for carbonated soft drinks. However, their superior properties extend their utility.

- Carbonated Soft Drinks: This is the most common use. The chips ensure fizz retention and bottle integrity.

- Mineral Water and Still Water: While not carbonated, still water bottles benefit. They gain from the chips’ clarity and strength.

- Edible Oils: The barrier properties help protect oils from oxidation. This maintains freshness.

- Food Jars: Certain food products benefit from the rigid packaging. This includes sauces and pickles.

- Pharmaceutical Bottles: The purity and barrier properties are vital. They protect sensitive pharmaceutical liquids.

MT Royal: Your Best JBF High IV PET Chips Supplier

Choosing the right supplier is critical. MT Royal stands out as a premier JBF High IV PET Chips for carbonated bottles supplier. We pride ourselves on our commitment to quality. Our supply chain is robust and reliable. We ensure timely delivery of your orders.

- Reliable Sourcing: We source directly from trusted manufacturers. This guarantees authentic JBF PET Chips.

- Stringent Quality Control: Every batch undergoes rigorous testing. We ensure it meets international standards.

- Competitive Pricing: We offer excellent value for your investment. Our prices are highly competitive.

- Exceptional Customer Service: Our team is knowledgeable and responsive. We assist you at every step.

- Global Reach: We serve clients worldwide. Our logistics network is efficient.

Our extensive experience in the petrochemical industry sets us apart. We understand the nuances of PET chip supply. We offer tailored solutions to meet specific client needs. When you partner with MT Royal, you gain more than just a supplier. You gain a strategic ally. We are dedicated to your success. Our commitment to quality ensures your production runs smoothly. We help you achieve superior bottle quality.

Conclusion

The quality of your PET chips directly impacts your final product. JBF High IV PET Chips offer an unparalleled combination of clarity, strength, and barrier properties. These attributes are essential for carbonated beverage bottles. For businesses seeking a dependable JBF High IV PET Chips for carbonated bottles supplier, MT Royal is the answer. Our dedication to excellence, competitive offerings, and customer-centric approach make us the preferred partner. Contact MT Royal today to discuss your requirements. Experience the difference a reliable supplier makes.

Reviews

There are no reviews yet.