In the modern industrial landscape, precision and automation are no longer luxuries but necessities. This holds especially true for industries where accurate chemical management is paramount, such as the food industry. Businesses in this sector constantly seek innovative solutions to optimize their processes, ensure product quality, and maintain operational efficiency. This is precisely where a PLC-Controlled Chemical Dosing System – For Sale from MT Royal becomes an invaluable asset. This advanced system offers unparalleled accuracy and reliability, transforming how chemicals are introduced into various processes. MT Royal, a leader in providing cutting-edge industrial solutions, understands the intricate demands of these industries and has engineered a system that meets and exceeds these expectations. Their commitment to technological advancement and customer satisfaction is evident in every aspect of this sophisticated dosing solution.

Introducing the Advanced PLC-Controlled Chemical Dosing System

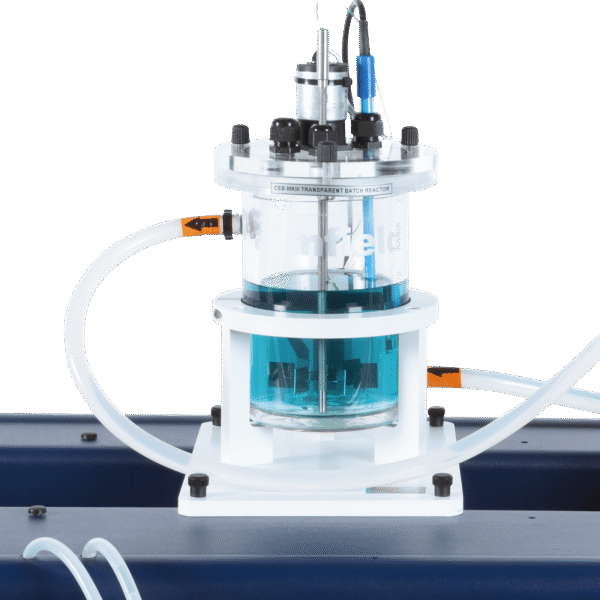

The PLC-Controlled Chemical Dosing System offered by MT Royal is a state-of-the-art solution designed to provide precise and automated control over chemical additions. This system integrates a Programmable Logic Controller (PLC) as its central intelligence, allowing for highly accurate and repeatable dosing sequences. Unlike manual or less sophisticated automated systems, a PLC-controlled unit minimizes human error and ensures consistency, which is crucial for sensitive applications like those found in the food industry. The system is engineered to handle a wide range of chemicals, from sanitizers and disinfectants to pH adjusters and processing aids, making it incredibly versatile. Its robust construction and intelligent design ensure long-term reliability and minimal maintenance requirements. This system represents a significant leap forward in chemical management, offering a comprehensive solution for businesses looking to enhance their operational efficiency and product quality. MT Royal prides itself on delivering solutions that are both technologically advanced and user-friendly.

Advantages of a PLC-Controlled System in the Food Industry

The advantages of implementing a PLC-controlled chemical dosing system, especially in the food industry, are numerous and impactful. Firstly, precision and accuracy are vastly improved. The PLC can precisely control the volume and timing of chemical delivery, preventing under-dosing or over-dosing, both of which can lead to quality control issues or wasted resources. This level of accuracy is critical for maintaining consistent product formulations and ensuring food safety standards are met. Secondly, enhanced safety is a significant benefit. Automated dosing reduces human contact with potentially hazardous chemicals, minimizing the risk of spills, exposures, and accidents. The system can also incorporate safety interlocks and alarms to further enhance operational security. Thirdly, operational efficiency is dramatically boosted. Automation frees up personnel for other tasks, reduces labor costs, and allows for continuous operation without constant supervision. The system’s ability to maintain consistent chemical levels also contributes to more stable and predictable production processes. Fourthly, data logging and reporting capabilities provide invaluable insights into chemical consumption and process performance. This data can be used for optimization, compliance, and troubleshooting. Finally, the scalability and adaptability of a PLC-based system mean it can be tailored to various plant sizes and modified to accommodate future needs. These benefits directly translate into cost savings, improved product quality, and a safer working environment for businesses in the food industry.

Key Specifications of Our Chemical Dosing System

The PLC-Controlled Chemical Dosing System from MT Royal is designed with a focus on performance, reliability, and ease of integration. The core of the system is a high-performance PLC, typically from a reputable manufacturer, chosen for its processing power and programming flexibility. This PLC is interfaced with a user-friendly Human-Machine Interface (HMI) touch screen, providing intuitive control and real-time monitoring of all dosing parameters. The dosing pumps themselves are typically positive displacement pumps, such as diaphragm or peristaltic pumps, selected for their accuracy and compatibility with a wide range of chemicals. Material compatibility is a critical consideration, and all wetted parts of the system are constructed from corrosion-resistant materials like PVC, PP, PVDF, or stainless steel, depending on the specific chemical application. The system can be configured with multiple dosing points and flow rates to accommodate diverse process requirements. Furthermore, it incorporates various sensors for level monitoring, flow verification, and pressure sensing, ensuring precise operation and immediate alerts in case of anomalies. Communication protocols like Modbus or Ethernet/IP are often supported, allowing for seamless integration with existing SCADA systems or plant-wide control networks. The compact design ensures a minimal footprint, making it suitable for facilities with limited space. Each system undergoes rigorous testing to ensure it meets MT Royal’s stringent quality standards before deployment.

Applications of the MT Royal Dosing System

The versatility of MT Royal’s PLC-Controlled Chemical Dosing System makes it suitable for a vast array of applications within the food industry and beyond. In food processing, it is indispensable for precise pH adjustment in various stages of production, such as beverage manufacturing, dairy processing, and fruit and vegetable preservation. It’s also crucial for adding sanitizers and disinfectants to ensure hygiene in cleaning-in-place (CIP) and sterilization-in-place (SIP) systems, preventing microbial contamination. For water treatment within food plants, the system efficiently doses coagulants, flocculants, and disinfectants to ensure the quality of process water and wastewater. Other applications include the accurate addition of flavoring agents, preservatives, and nutritional supplements to food products, ensuring consistent taste and quality. Beyond the food industry, this system finds utility in municipal water treatment plants for chlorination and fluoridation, industrial wastewater treatment for contaminant removal, and even in pharmaceutical manufacturing for precise reagent addition. Its adaptability means it can be configured for batch processing, continuous flow systems, or on-demand dosing, making it a truly flexible solution for diverse operational needs.

Purchasing Your PLC-Controlled Chemical Dosing System – For Sale from MT Royal

When considering a PLC-Controlled Chemical Dosing System – For Sale, choosing the right supplier is just as important as selecting the right technology. MT Royal stands out as a premier provider, offering not only cutting-edge equipment but also comprehensive support and expertise. Their team of engineers and technical specialists works closely with clients to understand their specific needs and custom-design systems that perfectly integrate with existing infrastructure. The purchasing process with MT Royal is streamlined and customer-centric, beginning with a detailed consultation to assess your requirements and recommend the most suitable dosing solution. They provide transparent pricing, detailed technical specifications, and clear project timelines. Beyond the initial sale, MT Royal offers robust after-sales support, including installation assistance, commissioning services, operator training, and ongoing technical support. Their commitment to long-term client relationships ensures that your investment continues to deliver optimal performance for years to come. By choosing MT Royal, you are not just acquiring a piece of equipment; you are partnering with a company dedicated to your operational success and long-term satisfaction.

Final Thoughts on the PLC-Controlled Chemical Dosing System – For Sale

The demand for precision, automation, and safety in industrial processes, especially within the food industry, continues to grow. A PLC-Controlled Chemical Dosing System – For Sale represents a significant step forward in meeting these demands, offering unparalleled accuracy, reliability, and efficiency in chemical management. MT Royal, with its unwavering commitment to innovation and customer satisfaction, is at the forefront of providing these advanced solutions. Investing in such a system is not merely an expenditure; it is a strategic decision that leads to improved product quality, reduced operational costs, enhanced safety, and greater peace of mind. For any business in the food industry looking to optimize their chemical dosing processes and secure a competitive edge, the intelligent, robust, and reliable systems offered by MT Royal provide a clear path to achieving these goals. Their expertise and dedication ensure that businesses can confidently move towards more automated and precise operations, setting new standards for efficiency and quality in their respective fields.

Reviews

There are no reviews yet.