In the demanding realms of pharmaceutical and cosmetic manufacturing, precision and quality are paramount. Every step in the production process must adhere to stringent standards, from ingredient sourcing to final product packaging. A critical, often overlooked, stage in tablet production is dedusting. This seemingly minor step plays a significant role in ensuring product integrity, patient safety, and regulatory compliance. This is where a Rotary Tablet Deduster Machine – For Sale becomes an indispensable asset, offering a sophisticated solution for removing loose dust and burrs from tablets after compression. MT Royal, a leading supplier in the industry, offers state-of-the-art dedusting solutions that meet the diverse needs of modern manufacturers.

Introduction to the Rotary Tablet Deduster Machine – For Sale

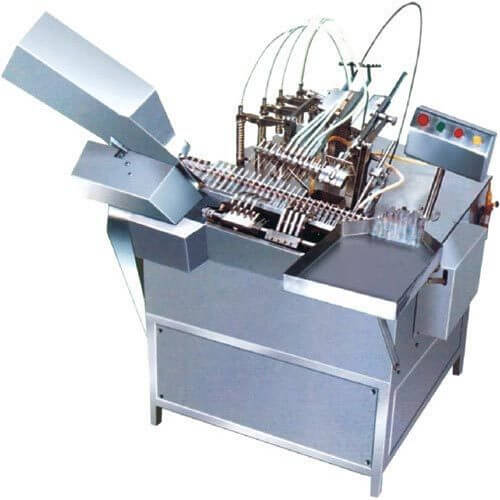

The Rotary Tablet Deduster Machine – For Sale is a specialized piece of equipment designed to gently and effectively remove excess powder or dust from the surface of tablets after they have been compressed. During the tablet compression process, some fine particles of the raw material can adhere to the tablet surface or form small burrs along the edges. If left unaddressed, these particles can lead to several problems. They can contaminate packaging, interfere with subsequent coating processes, affect tablet appearance, and potentially impact the precise dosage of the medication.

MT Royal understands these challenges and provides dedusting machines engineered for optimal performance. Our machines employ a unique vibratory and rotating motion, often combined with vacuum suction, to dislodge and collect loose particles. This ensures that only clean, well-formed tablets proceed to the next stage of production, enhancing overall product quality and minimizing waste. As a vital component in the pharmaceutical and cosmetic production line, a reliable deduster is a non-negotiable investment for any company committed to excellence.

Advantages of Using a Rotary Tablet Deduster Machine

Integrating a Rotary Tablet Deduster Machine into your production line offers a multitude of advantages that extend beyond mere dust removal. These benefits directly contribute to improved product quality, operational efficiency, and regulatory compliance within the Pharmaceutical & Cosmetic sector.

Firstly, enhanced product quality is a primary benefit. By eliminating loose powder, dedusters ensure a cleaner, more appealing tablet. This is crucial for consumer perception and acceptance, especially in the cosmetic industry where aesthetics play a significant role. For pharmaceuticals, a clean tablet surface is essential for consistent and effective coating application, which often provides protective layers, modified release properties, or improved palatability.

Secondly, these machines significantly reduce cross-contamination risks. Dust particles can easily spread throughout a facility, potentially contaminating other products or batches. A deduster, especially one with integrated vacuum suction, effectively contains these particles, creating a cleaner working environment and minimizing the risk of cross-contamination between different products. This is particularly important in facilities handling multiple active pharmaceutical ingredients.

Thirdly, operational efficiency is greatly improved. With automated dedusting, manual cleaning processes are eliminated, saving valuable labor time and reducing potential human error. The continuous operation of a rotary deduster allows for a seamless flow of tablets, preventing bottlenecks in the production line and ensuring a higher throughput. This leads to increased productivity and a more streamlined manufacturing process.

Finally, compliance with Good Manufacturing Practices (GMP) is a critical advantage. Regulatory bodies worldwide impose strict guidelines on pharmaceutical and cosmetic product quality and manufacturing processes. Dedusting is often a required step to meet these standards, ensuring that products are free from foreign matter and are of consistent quality. Investing in a high-quality Rotary Tablet Deduster Machine demonstrates a commitment to these regulatory requirements, facilitating easier audits and approvals.

Product Specifications

The Rotary Tablet Deduster Machine offered by MT Royal is engineered with precision and built to the highest industry standards. These machines are designed for robust performance, ease of use, and minimal maintenance, making them an ideal choice for the Pharmaceutical & Cosmetic sector.

Our dedusters feature a compact and ergonomic design, ensuring they can be seamlessly integrated into existing production lines without requiring extensive space. They are typically constructed from high-grade stainless steel (SS304 or SS316L), a material widely recognized for its excellent corrosion resistance and hygienic properties, crucial for pharmaceutical and cosmetic applications. The contact parts are highly polished, preventing material adhesion and simplifying cleaning and validation processes.

Key specifications often include adjustable tablet inlet and outlet heights, allowing for flexible integration with various tablet presses and downstream equipment. The machines are equipped with advanced vibration systems that gently yet effectively remove dust without damaging the tablets. Variable speed control for the rotation and vibration mechanisms provides versatility, allowing operators to optimize the dedusting process for different tablet sizes, shapes, and formulations.

Furthermore, MT Royal’s Rotary Tablet Dedusters often come with an integrated or optional vacuum dust extraction system. This system efficiently collects the dislodged dust into a sealed container, preventing airborne particulate matter and ensuring a cleaner production environment. Safety features, such as interlocks and emergency stop buttons, are standard, ensuring operator safety during operation and maintenance. The design also facilitates quick dismantling for cleaning and changeover, significantly reducing downtime between batches.

Applications of the Rotary Tablet Deduster Machine

The versatility of the Rotary Tablet Deduster Machine makes it an indispensable asset across various segments within the Pharmaceutical & Cosmetic industries. Its primary function remains consistent: to ensure the cleanliness and integrity of tablets. However, its specific applications can vary depending on the product and subsequent processing steps.

In the pharmaceutical sector, these machines are crucial for producing a wide range of oral solid dosage forms, including standard tablets, capsules, and even certain types of lozenges. After compression, pharmaceutical tablets often proceed to coating. A clean, dust-free surface is essential for the uniform adhesion of coating materials, which can be functional (e.g., enteric coating for delayed release) or aesthetic (e.g., colored coatings). Without proper dedusting, coating defects like “orange peel” or “twinning” can occur, leading to batch rejection.

For the cosmetic industry, the application is equally vital. Products like pressed powders, effervescent bath tablets, or even certain solid shampoos often undergo a compression process. The presence of dust on these items can detract from their visual appeal and user experience. A Rotary Tablet Deduster Machine ensures that these cosmetic products have a smooth, clean finish, enhancing brand image and consumer satisfaction. The aesthetic quality of cosmetic products is paramount, and a deduster contributes significantly to achieving this.

Moreover, dedusters are essential before packaging. Dust on tablets can lead to unsightly residue inside blister packs or bottles, making the product appear substandard. By ensuring tablets are clean before packaging, the deduster contributes to a professional and appealing final product presentation, which is critical for market success. The machine’s ability to handle various tablet shapes and sizes further broadens its applicability, making it a flexible solution for diverse manufacturing needs.

Purchasing Your Rotary Tablet Deduster Machine from MT Royal

When considering the acquisition of a Rotary Tablet Deduster Machine – For Sale, partnering with a reputable supplier like MT Royal is paramount. MT Royal has established itself as a trusted name in providing high-quality pharmaceutical and cosmetic machinery, offering not just equipment but comprehensive solutions tailored to your specific production requirements.

Choosing MT Royal means gaining access to a wide range of dedusting machines, each designed to meet different production capacities and specifications. Our team of experts works closely with clients to understand their unique needs, guiding them through the selection process to ensure they invest in the most suitable model for their operations. This personalized approach guarantees that you receive a machine that seamlessly integrates into your existing workflow and delivers optimal performance.

Beyond the initial sale, MT Royal provides exceptional after-sales support, including installation assistance, operator training, and readily available spare parts. We understand that downtime can be costly in manufacturing, which is why our dedicated service team is committed to ensuring your machine operates efficiently throughout its lifespan. Our commitment to customer satisfaction extends to providing ongoing technical support and maintenance advice, ensuring the longevity and reliability of your investment.

Furthermore, MT Royal’s Rotary Tablet Deduster Machines are competitively priced, offering excellent value without compromising on quality or performance. We prioritize transparency and integrity in all our dealings, ensuring a smooth and satisfactory purchasing experience. Investing in an MT Royal deduster is an investment in reliability, efficiency, and the long-term success of your pharmaceutical or cosmetic production.

Final Thoughts on the Rotary Tablet Deduster Machine

The Rotary Tablet Deduster Machine – For Sale stands as an indispensable piece of equipment in the modern pharmaceutical and cosmetic manufacturing landscape. Its role in ensuring product quality, enhancing operational efficiency, and upholding regulatory compliance cannot be overstated. From preventing cross-contamination to facilitating flawless tablet coating and ensuring appealing product presentation, the benefits of a high-quality deduster are far-reaching.

For companies operating within the Pharmaceutical & Cosmetic sector, investing in a reliable deduster is not merely an option but a necessity for maintaining competitive edge and meeting stringent industry standards. MT Royal is proud to be at the forefront of supplying these critical machines, offering advanced solutions that cater to the evolving demands of the global market. Our dedication to quality, customer service, and innovative engineering ensures that when you choose a Rotary Tablet Deduster Machine from MT Royal, you are investing in a future of cleaner, higher-quality tablet production.

Maximizing Efficiency with Your Rotary Tablet Deduster

Beyond the immediate benefits, optimizing the use of your Rotary Tablet Deduster Machine can further enhance overall production efficiency. Regular maintenance, proper calibration, and continuous monitoring are key to ensuring peak performance and extending the lifespan of the equipment. MT Royal provides detailed operational manuals and training to help your team master the use of these advanced machines. This ensures that every tablet leaving your production line is of the highest possible quality, free from unwanted dust, and ready for market.

Reviews

There are no reviews yet.