In the intricate world of manufacturing, finding a reliable partner for bespoke components is crucial. When it comes to durable, cost-effective, and precisely engineered metal parts, Sand Cast Custom Parts Manufacturer play an indispensable role. This traditional yet highly evolved casting method offers unparalleled versatility for creating complex shapes and large components across various industries. At MT Royal, we pride ourselves on being a leading expert in this domain, providing exceptional sand casting solutions tailored to the unique demands of our clients. Our commitment to quality, innovation, and customer satisfaction has established us as a trusted name in the industry, offering a comprehensive suite of services from design consultation to final product delivery. We understand that every project presents its own set of challenges and requirements, and our experienced team is dedicated to delivering solutions that not only meet but exceed expectations, ensuring optimal performance and longevity of the manufactured parts.

Product Introduction Sand Cast Custom Parts Manufacturer

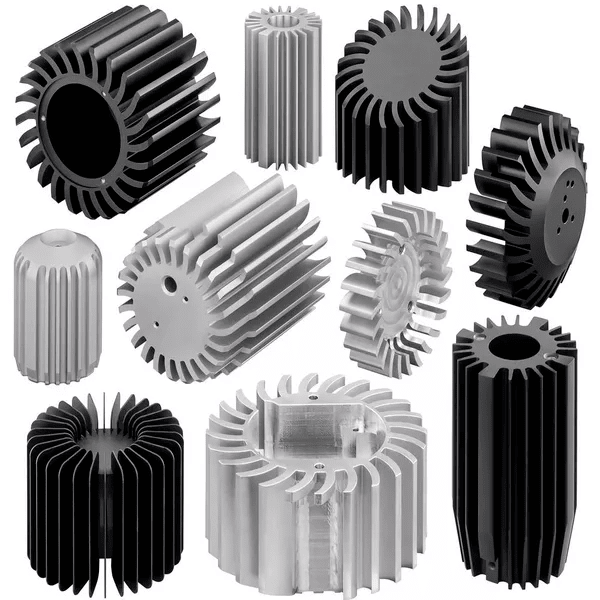

Sand casting is one of the oldest and most versatile methods for producing metal components, involving the creation of a mold using sand, which is then filled with molten metal. This process is particularly advantageous for manufacturing complex geometries and parts of varying sizes, making it an ideal choice for custom production. At MT Royal, our product introduction in the realm of sand casting revolves around delivering bespoke solutions that cater to specific industrial needs. We utilize advanced techniques and state-of-the-art equipment to ensure the highest quality and precision in every custom part we produce. Our engineers work collaboratively with clients, translating intricate designs into tangible, high-performance components. Whether it’s a prototype or a large-scale production run, our focus remains on achieving dimensional accuracy, superior surface finish, and optimal material integrity. The flexibility of sand casting allows us to work with a diverse range of metals, including various types of iron, steel, aluminum, and bronze, offering a broad spectrum of applications.

Advantages of the Product

The advantages of choosing sand cast custom parts are numerous and significant, particularly when working with a reputable Sand Cast Custom Parts Manufacturer like MT Royal. Firstly, sand casting is highly cost-effective for both small and large production runs. The tooling costs are relatively lower compared to other casting methods, making it an economical choice for custom projects and prototyping. Secondly, it offers remarkable flexibility in terms of design complexity and part size. Manufacturers can produce intricate shapes and very large components that would be challenging or impossible with other casting techniques. This versatility allows for greater freedom in product design and application. Thirdly, sand casting can accommodate a wide range of ferrous and non-ferrous metals, providing excellent material choice for various performance requirements. This adaptability ensures that the final product possesses the desired mechanical properties, such as strength, durability, and resistance to wear or corrosion. Furthermore, the ability to create internal cavities and complex internal structures without additional machining significantly reduces production time and costs. MT Royal leverages these inherent advantages to deliver superior custom parts that meet stringent industry standards and client specifications, ensuring long-term reliability and performance in diverse operational environments.

Product Specifications

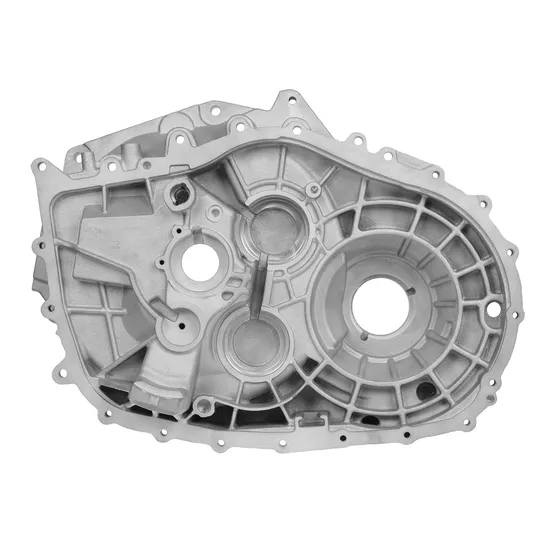

When considering sand cast custom parts, understanding the detailed product specifications is essential for ensuring the components meet their intended functional requirements. At MT Royal, we adhere to rigorous standards in defining the specifications for each custom part. This includes precise details regarding material composition, as we work with a wide array of alloys such as gray iron, ductile iron, carbon steel, stainless steel, aluminum alloys, and brass. The choice of material is often dictated by the application’s demands for strength, corrosion resistance, weight, and thermal properties. Dimensional tolerances are meticulously controlled, typically ranging from mm to mm depending on the size and complexity of the part, ensuring perfect fit and function within larger assemblies. Surface finish is another critical specification, often ranging from 125 to 500 micro-inches RMS, which can be further refined through post-casting processes like machining or shot blasting. Weight limits can vary significantly, from just a few grams to several tons, demonstrating the scalability of sand casting. We also specify heat treatment requirements, if any, to achieve desired mechanical properties like hardness, tensile strength, and yield strength. Non-destructive testing (NDT) methods such as radiographic inspection, ultrasonic testing, and magnetic particle inspection are also part of our quality control specifications to ensure internal integrity and detect any potential flaws. Each custom part from MT Royal is meticulously crafted to meet these precise specifications, guaranteeing reliability and performance in demanding applications.

Product Applications

The versatility of sand cast custom parts makes them indispensable across a vast spectrum of industries and applications. At MT Royal, the custom components we manufacture find their utility in critical systems where durability, strength, and precise engineering are paramount. In the automotive industry, sand castings are widely used for engine blocks, cylinder heads, transmission cases, and brake components, where they must withstand extreme temperatures and pressures. The heavy machinery sector relies on sand cast parts for robust components in construction equipment, agricultural machinery, and mining equipment, including gear housings, structural frames, and large levers, due to their ability to produce large, strong, and durable parts economically. The energy sector, encompassing oil and gas, power generation, and renewable energy, utilizes sand castings for valve bodies, pump housings, turbine components, and intricate manifold systems that operate under high-stress conditions. In the marine industry, sand cast custom parts are essential for propeller components, engine parts, and specialized fittings that require high corrosion resistance and structural integrity in harsh saltwater environments. Furthermore, general industrial applications such, as manufacturing equipment, industrial pumps, and specialized tooling, frequently incorporate sand cast components for their robust performance and cost-effectiveness. The ability to customize dimensions, materials, and designs ensures that MT Royal’s sand cast parts seamlessly integrate into diverse and demanding operational settings, providing reliable and long-lasting solutions for our clients worldwide.

Purchasing This Product from MT Royal

When you are ready to invest in high-quality sand cast custom parts, purchasing from MT Royal offers a streamlined and highly reliable experience. As a dedicated Sand Cast Custom Parts Manufacturer, we prioritize customer satisfaction and product excellence from the initial inquiry to final delivery. Our purchasing process begins with a detailed consultation, where our experienced engineering team works closely with you to understand your specific requirements, including design specifications, material preferences, and intended applications. We provide expert advice on material selection and design optimization to ensure the most cost-effective and functionally superior solution. Following the design approval, we move to the quotation phase, offering transparent and competitive pricing without hidden costs. Our state-of-the-art manufacturing facilities in Finland are equipped with advanced sand casting technology, allowing us to maintain stringent quality control throughout the production cycle. We utilize robust quality assurance protocols, including meticulous inspections and testing, to guarantee that every custom part meets the agreed-upon specifications and industry standards. Logistics and timely delivery are also key components of our service. MT Royal has established efficient shipping channels to ensure that your custom parts arrive on schedule, regardless of your geographical location. By choosing MT Royal, you are partnering with a company that is committed to delivering not just a product, but a complete solution tailored to your unique needs, backed by unparalleled technical expertise and customer support.

Conclusion

The demand for customized, high-quality metal components continues to grow across industries, making the role of a proficient sand cast custom parts manufacturer more vital than ever. Throughout this article, we have explored the inherent advantages of sand casting, its broad range of applications, and the meticulous process involved in producing these essential parts. MT Royal stands at the forefront of this specialized manufacturing sector, consistently delivering superior sand cast custom parts that meet the most stringent industry standards. Our unwavering commitment to precision engineering, material excellence, and customer-centric service ensures that every component we produce is not just a part, but a reliable solution contributing to the success of our clients’ operations. By leveraging our deep expertise and advanced manufacturing capabilities, we empower businesses to achieve their design aspirations and operational efficiency goals. For future projects requiring robust, custom-engineered metal components, consider the proven capabilities and trusted partnership offered by MT Royal. We are ready to transform your complex designs into high-performance realities.

Reviews

There are no reviews yet.