In the intricate world of industrial machinery, worm gearboxes play a pivotal role, offering unique advantages in various applications. These essential components are designed for efficiency, durability, and precise control, making them indispensable in countless sectors. As a leading provider in the “Gears & Gearboxes” category, MT Royal has established itself as a reliable Worm Gearboxes Supplier, committed to delivering high-quality solutions that meet the diverse needs of modern industries. Our commitment extends beyond just supplying products; we aim to provide comprehensive support and expertise to ensure our clients achieve optimal performance from their machinery. The choice of a reputable supplier is crucial, impacting not only the immediate operational efficiency but also the long-term reliability and maintenance costs of your equipment.

Understanding Worm Gearboxes

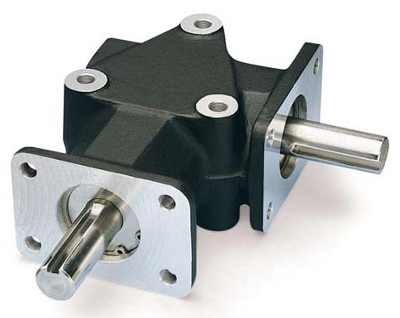

Worm gearboxes, also known as worm drive reducers, are a specific type of gear system where a worm (a screw-like gear) meshes with a worm wheel (a spur gear). This unique configuration allows for significant speed reduction and torque multiplication in a compact design. The mechanism’s inherent design prevents back-driving, meaning the worm wheel cannot turn the worm, providing a self-locking feature that is highly beneficial in applications requiring position holding or safety. This characteristic makes them particularly suitable for conveyor systems, lifting equipment, and various other industrial processes where maintaining a static load is critical. The simplicity of their design, coupled with their robust construction, ensures a long operational life with minimal maintenance requirements, making them a cost-effective solution for many businesses.

Advantages of Worm Gearboxes

The benefits of utilizing worm gearboxes are numerous, contributing significantly to their widespread adoption across various industries. One of the most notable advantages is their high reduction ratio in a relatively small footprint. This allows for substantial speed reduction without requiring multiple stages of gearing, simplifying machine design and reducing overall space requirements. Furthermore, the smooth and quiet operation of worm gearboxes is a significant plus, especially in environments where noise reduction is a priority. The inherent self-locking capability, as mentioned earlier, is another critical advantage, enhancing safety and control in applications where loads need to be held securely. This feature eliminates the need for additional braking mechanisms in many cases, further streamlining design and reducing costs. Their robust construction ensures excellent shock absorption and reliability, even in demanding operating conditions.

Product Specifications

When considering a worm gearbox, understanding its specifications is crucial for selecting the right model for your application. Key specifications typically include the reduction ratio, which dictates the output speed relative to the input speed. Torque capacity, measured in Newton-meters (Nm) or pound-feet (lb-ft), indicates the maximum torque the gearbox can transmit. Efficiency, often expressed as a percentage, reflects the power loss during operation. Other important specifications include shaft configuration (solid, hollow, or dual), mounting options (foot-mounted, flange-mounted), and input/output shaft diameters. Material construction also plays a vital role in durability and performance, with common materials including cast iron for housings and bronze for worm wheels. MT Royal offers a diverse range of worm gearboxes with varying specifications to cater to a wide array of industrial demands, ensuring you can find a product that precisely matches your technical requirements and operational environment.

Applications of Worm Gearboxes

The versatility of worm gearboxes makes them indispensable in a broad spectrum of industrial applications. They are commonly found in conveyor systems, where their high torque and self-locking capabilities are crucial for moving heavy loads safely and efficiently. In lifting equipment, such as hoists and cranes, they provide the necessary gear reduction and holding power. They are also widely used in packaging machinery for precise positioning and synchronized movements. Other applications include agricultural machinery, textile machinery, and various automation systems. Their compact design and ability to handle high shock loads make them ideal for space-constrained environments and demanding operational cycles. The specific requirements of each application will influence the selection of the appropriate worm gearbox, making it essential to consult with an experienced Worm Gearboxes Supplier like MT Royal to ensure optimal product selection and integration.

Purchasing Worm Gearboxes from MT Royal

When it comes to sourcing high-quality worm gearboxes, MT Royal stands out as a premier Worm Gearboxes Supplier. Our extensive inventory, combined with our deep understanding of industrial applications, positions us to provide tailored solutions for your specific needs. We pride ourselves on offering products that not only meet but often exceed industry standards for performance and reliability. Our commitment to customer satisfaction extends to providing expert technical support, ensuring that you select the most suitable gearbox for your operations. We understand the critical role these components play in your machinery, and our team is dedicated to helping you optimize your processes with the right equipment. Partnering with MT Royal means choosing a supplier that prioritizes quality, efficiency, and long-term value for your investment.

Conclusion

Worm gearboxes are critical components in numerous industrial applications, offering unique advantages in terms of speed reduction, torque multiplication, and self-locking capabilities. The continued innovation in their design and manufacturing ensures their relevance in an ever-evolving industrial landscape. As a dedicated Worm Gearboxes Supplier, MT Royal is committed to providing top-tier products and unparalleled service to our clients. Our comprehensive range of worm gearboxes, coupled with our expertise in the “Gears & Gearboxes” sector, makes us the ideal partner for all your industrial transmission needs. We invite you to explore our offerings and experience the MT Royal difference – a commitment to quality, reliability, and customer success.

Reviews

There are no reviews yet.