In the highly competitive global cocoa industry, the position of Top Cocoa Powder Manufacturers has become more critical than ever. Food producers, chocolate factories, beverage companies, and international distributors no longer search only for cocoa powder — they search for reliable manufacturing partners that can deliver consistent quality, stable supply, and predictable cost

Introduction: Global Cocoa Brands and the New Role of LATAMARKO

For decades, well-known global names such as Cargill, Altinmarka, Callebaut, JB Cocoa, and now LATAMARKO, have shaped the cocoa processing industry through large-scale production, advanced technology, and international distribution networks. These companies are recognized not simply as suppliers, but as strategic pillars of the food manufacturing ecosystem.

However, the modern buyer’s expectations have changed. Today’s professional buyers do not evaluate Top Cocoa Powder Manufacturers only by brand recognition. They assess long-term production stability, technical consistency, compliance with international standards, and the ability to adapt supply chains to volatile global market conditions.

This is where LATAMARKO emerges with a new production philosophy. Built on Spanish cocoa expertise and supported by the manufacturing and export power of MT ROYAL in TÜRKİYE, LATAMARKO represents a new generation among Top Cocoa Powder Manufacturers. The brand combines European processing knowledge with flexible global production infrastructure, offering manufacturers a dependable long-term partnership rather than a simple transactional supply relationship.

In an industry where fluctuations in raw material cost, logistics challenges, and regulatory pressures constantly reshape the market, LATAMARKO positions itself as a solution provider — delivering controlled quality, stable supply programs, and transparent cost structures that protect its partners’ profitability.

As global demand for high-quality cocoa ingredients continues to rise, the role of Top Cocoa Powder Manufacturers becomes central to the success of food producers worldwide. LATAMARKO is not only part of this elite group — it is actively redefining what modern cocoa manufacturing leadership means

How to Identify a Reliable Cocoa Powder Manufacturer

For decades, globally respected names such as Cargill, Altinmarka, Callebaut, JB Cocoa, and today LATAMARKO, have played a defining role in shaping the cocoa processing industry. Through large-scale production capabilities, advanced processing technologies, and extensive international distribution networks, these companies have become far more than ingredient suppliers — they function as strategic foundations of the modern food manufacturing ecosystem.

Yet the expectations of today’s buyers have fundamentally evolved. Modern purchasing managers and product developers no longer evaluate Top Cocoa Powder Manufacturers solely by brand reputation. Instead, they focus on long-term production reliability, technical consistency, strict compliance with international standards, and the supplier’s ability to respond effectively to rapidly changing global market conditions.

This shift in market priorities is where LATAMARKO introduces a new production philosophy. Rooted in Spanish cocoa expertise and strengthened by the manufacturing and export infrastructure of MT ROYAL in TÜRKİYE, LATAMARKO represents a new generation among Top Cocoa Powder Manufacturers. The brand seamlessly integrates European processing know-how with flexible global production systems, offering its partners not merely a source of supply, but a dependable long-term collaboration model.

In an industry constantly influenced by fluctuations in raw material prices, logistical complexity, and tightening regulatory requirements, LATAMARKO positions itself as a solution-oriented partner. Through disciplined quality control, stable supply planning, and transparent cost management, the brand actively protects its partners’ operational stability and profitability.

As worldwide demand for premium cocoa ingredients continues to grow, the role of Top Cocoa Powder Manufacturers becomes increasingly central to the success of food producers across every market. LATAMARKO is not simply a member of this elite group — it is actively redefining what leadership in modern cocoa manufacturing truly means

Factory vs Trader: Who Should You Buy Cocoa Powder From

When sourcing cocoa powder, one of the most important strategic decisions a buyer must make is whether to work directly with a factory or through a trader. While both models exist in the global market, the long-term impact on product quality, cost control, and supply security is significantly different.

A true cocoa powder manufacturer controls the entire production chain — from cocoa bean sourcing and roasting to alkalization, milling, and final quality inspection. This vertical integration allows factories to maintain consistent specifications, stable quality, and predictable pricing structures. Buyers benefit from direct technical communication, customized product development, and full traceability across every batch.

In contrast, most traders do not own production facilities. They source from multiple factories, often changing suppliers based on short-term market conditions. While traders may offer quick availability or short-term pricing opportunities, this model frequently leads to inconsistency in color, flavor, moisture levels, and processing behavior. Over time, these variations create formulation instability, production delays, and higher operational costs.

Another critical difference lies in pricing transparency. Purchasing directly from a factory allows buyers to access true factory-level cocoa powder pricing, eliminating intermediary margins and hidden markups. Traders, by necessity, add layers of cost that are not always visible in initial quotations but appear over the course of long-term cooperation.

Supply reliability is equally important. Factories plan production capacity months in advance and build stable supply programs for their customers. Traders often rely on spot availability, which exposes buyers to shortages, delayed shipments, and sudden price volatility during high-demand periods.

For manufacturers seeking long-term stability, technical consistency, and predictable cost management, direct cooperation with a factory is not simply an option — it is a competitive advantage. This is precisely why leading food producers increasingly choose production partners like LATAMARKO, where manufacturing control, export expertise, and long-term partnership philosophy replace transactional trading models

What Quality Standards Matter in Cocoa Powder Production

In the global cocoa industry, quality is not a slogan — it is a measurable system of controls that determines whether a supplier can deliver consistent performance, regulatory compliance, and long-term commercial reliability. For professional buyers evaluating Top Cocoa Powder Manufacturers, understanding which quality standards truly matter is essential to protecting both product integrity and business profitability.

At the foundation of any serious cocoa operation lies a comprehensive food safety management system. Certifications such as ISO 22000, HACCP, and FSSC 22000 are no longer optional in international trade; they represent the minimum operational framework required to ensure hygienic production, contamination prevention, and process traceability. Manufacturers operating under these systems demonstrate their ability to control risks at every stage of cocoa processing — from raw material intake to final packaging.

Beyond system certifications, technical quality parameters define the real performance of cocoa powder in production. Critical indicators include fat content stability, controlled alkalization profiles, uniform color development, moisture regulation, and precise pH management. These parameters determine not only taste and appearance, but also processing behavior, shelf life, and formulation consistency across large-scale manufacturing lines.

Microbiological control is another decisive factor. Reputable manufacturers implement continuous laboratory testing for pathogens, yeast, mold, and total plate count. Without this discipline, cocoa powder becomes a silent risk that can compromise entire production batches and trigger costly product recalls.

Traceability and documentation complete the quality structure. Professional cocoa powder manufacturers provide detailed certificates of analysis, certificates of origin, allergen statements, non-GMO declarations, and regulatory compliance documents aligned with the requirements of destination markets. This documentation is essential for import clearance, audit processes, and brand protection.

Ultimately, quality standards are not simply about meeting regulations — they define whether a cocoa powder supplier can operate as a long-term strategic partner. This is why brands like LATAMARKO invest heavily in disciplined quality management, advanced process control, and transparent documentation. For buyers seeking reliability in both product performance and commercial cooperation, strict adherence to these quality standards is non-negotiable

Cocoa Powder Grades and Their Industrial Applications

Cocoa powder is not a single standardized product. It exists in multiple technical grades, each engineered for specific industrial functions, processing conditions, and end-product requirements. Understanding these grades is essential for buyers who want to optimize performance, control cost, and achieve consistent product quality across large-scale production.

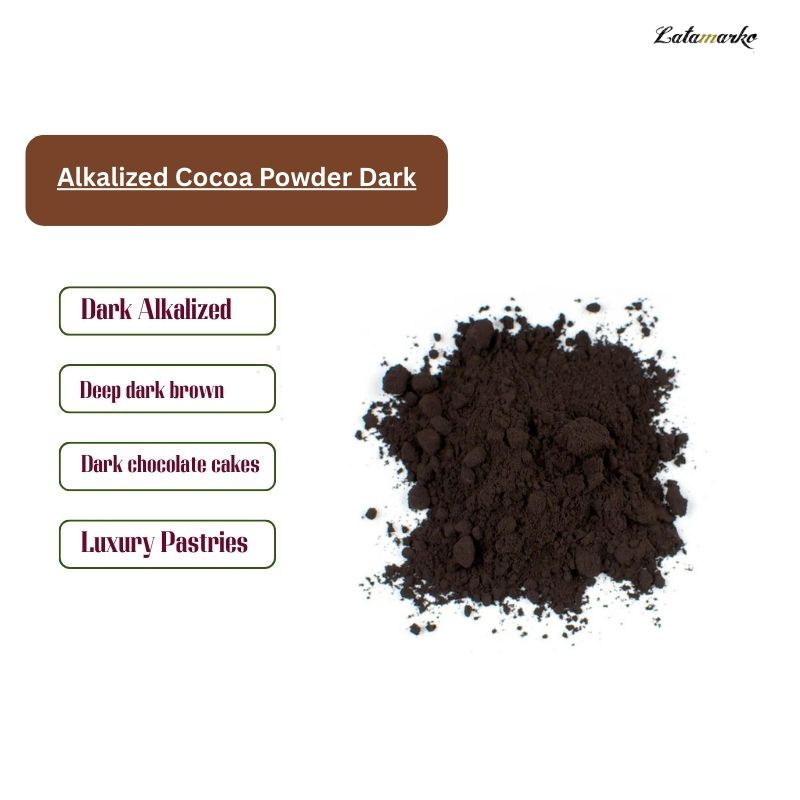

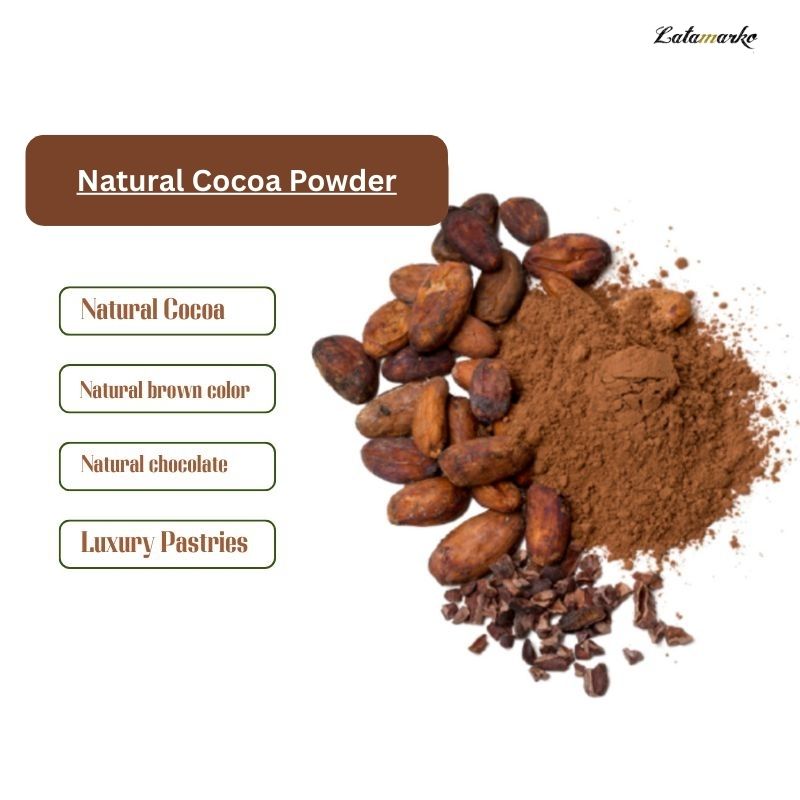

The first major classification is based on processing type: natural cocoa powder and alkalized cocoa powder. Natural cocoa powder offers sharper acidity and lighter color, while alkalized cocoa powder provides smoother flavor, darker color tones, better solubility, and greater formulation stability. For most industrial food applications, alkalized cocoa is preferred due to its controlled behavior and predictable performance.

Within these categories, cocoa powder is further segmented by fat content. Low-fat cocoa powders (8–10 percent) are commonly used in beverage mixes and dry formulations where dispersibility and cost efficiency are priorities. Medium-fat grades (10–12 percent) serve as the industry standard for bakery and confectionery applications, offering balanced mouthfeel and flavor. High-fat cocoa powders (12–22 percent) are selected for premium chocolate products, fillings, and coatings where richness and texture are critical.

Color classification defines another important grade structure. Light brown cocoa is often used in milk-based beverages and light bakery products. Reddish brown grades enhance visual warmth in cakes and biscuits. Dark brown cocoa delivers strong cocoa identity in chocolate and desserts. Black cocoa, produced through heavy alkalization, is reserved for specialty bakery, sandwich cookies, and premium confectionery where intense color contrast and visual impact are essential.

Each grade also carries specific functional behavior: particle size, moisture tolerance, pH profile, flowability, and dispersion characteristics. These properties determine how cocoa powder performs during mixing, baking, conching, extrusion, and shelf-life storage.

Leading Top Cocoa Powder Manufacturers design their grade portfolios to meet these precise industrial needs. Brands like LATAMARKO offer tailored cocoa solutions that align processing performance with end-product objectives, allowing manufacturers to maintain quality consistency while optimizing production cost and efficiency.

How Cocoa Origin Affects Quality and Price

Cocoa origin is one of the most influential factors in determining both the quality and the final cost of cocoa powder. For professional buyers working with Top Cocoa Powder Manufacturers, understanding the relationship between bean origin, processing behavior, and market price is essential for making strategic sourcing decisions.

Different cocoa-growing regions produce beans with distinct characteristics shaped by climate, soil composition, farming practices, and post-harvest processing. West African origins, which dominate global production, are valued for their strong cocoa intensity and reliable fat content. Latin American beans are often selected for their refined flavor profiles and smoother processing behavior. Selected Asian origins provide unique aromatic notes and growing importance in specialty cocoa markets.

These intrinsic differences directly affect fermentation quality, fat yield, flavor development, and roasting performance. Beans with higher fermentation stability and predictable fat composition allow manufacturers to achieve consistent alkalization, controlled color development, and stable final cocoa powder quality. This stability reduces formulation adjustments, production losses, and long-term operational cost.

However, higher-grade cocoa origins come with increased procurement expenses. Improved agricultural management, careful fermentation, and controlled drying processes raise raw material costs but deliver measurable benefits in production performance and product consistency. For manufacturers, this investment often results in lower waste, improved shelf life, and stronger brand reputation in the final consumer product.

Cocoa origin also influences market pricing dynamics. Weather conditions, geopolitical developments, regional harvest yields, and transportation infrastructure all affect availability and export cost from each producing region. These fluctuations are reflected in the international cocoa market and ultimately in the pricing structures offered by Top Cocoa Powder Manufacturers.

Leading producers such as LATAMARKO manage these variables through diversified sourcing strategies and long-term supplier partnerships. By combining selected origins with advanced processing control, LATAMARKO ensures stable quality output and more predictable cost structures for its global customers

Best Cocoa Powder for Chocolate Manufacturing

In chocolate production, cocoa powder is not simply a flavoring agent — it is a structural and functional component that directly influences texture, taste, color, processing behavior, and cost efficiency. For manufacturers working with Top Cocoa Powder Manufacturers, selecting the right cocoa powder grade is a strategic decision that affects every stage of production.

The ideal cocoa powder for chocolate manufacturing is typically alkalized cocoa powder with medium to high fat content. Alkalized cocoa provides smoother flavor, reduced acidity, deeper color development, and superior dispersion compared to natural cocoa. These properties ensure stable conching performance, uniform color distribution, and consistent sensory profiles across production batches.

Fat content plays a critical role in chocolate formulation. Cocoa powders with 10–12 percent fat are widely used for compound chocolate, chocolate coatings, and fillings, offering balanced mouthfeel and efficient processing. Higher fat grades are preferred for premium chocolate applications where richness, smoothness, and flavor release are essential.

Color selection is equally important. Dark brown cocoa powders deliver strong cocoa identity in milk and dark chocolate products, while black cocoa powders are reserved for specialty applications requiring intense visual contrast and unique flavor profiles. Each color grade must maintain strict pH control and moisture stability to avoid processing instability.

Particle size and flowability determine how cocoa integrates into the chocolate mass. Finely milled cocoa powder with controlled moisture content ensures smooth texture, consistent viscosity, and efficient energy usage during refining and conching.

Leading Top Cocoa Powder Manufacturers design chocolate-grade cocoa powders to meet these precise technical demands. Brands such as LATAMARKO offer specialized cocoa solutions for chocolate producers, enabling manufacturers to achieve consistent quality, predictable performance, and long-term cost control

Best Cocoa Powder for Bakery and Confectionery

In bakery and confectionery production, cocoa powder serves both a sensory and functional role. It defines flavor intensity, visual appeal, texture, and processing efficiency. For manufacturers working with Top Cocoa Powder Manufacturers, selecting the correct cocoa powder grade is essential for achieving consistent product quality while maintaining cost efficiency.

For most bakery and confectionery applications, alkalized cocoa powder is the preferred choice. Its smoother flavor profile, deeper color tones, and improved solubility make it ideal for cakes, biscuits, cookies, fillings, creams, coatings, and dessert formulations. Unlike natural cocoa, alkalized cocoa integrates more uniformly into doughs and batters, ensuring stable color and flavor development during baking.

Fat content selection depends on the final product. Medium-fat cocoa powders (10–12 percent) offer balanced flavor release and processing stability, making them suitable for the majority of bakery items. Lower fat grades are commonly used in dry mixes and powdered formulations, while higher fat cocoa powders enhance richness and mouthfeel in premium confectionery products.

Color grading is a critical design element. Reddish brown cocoa powders are favored for warm-toned baked goods, while dark brown grades create a strong cocoa identity in cookies and chocolate-flavored desserts. Black cocoa is used selectively in specialty confectionery where dramatic visual contrast and distinctive flavor are required.

Particle size and moisture control ensure smooth mixing, predictable dough behavior, and consistent baking performance. Poorly controlled cocoa powder leads to uneven texture, inconsistent coloring, and increased product rejection.

Leading Top Cocoa Powder Manufacturers engineer bakery-grade cocoa powders to meet these strict technical requirements. LATAMARKO, in particular, supplies customized cocoa solutions that allow bakeries and confectionery producers to maintain high product standards, reduce formulation variability, and protect long-term profitability

Alkalized vs Natural Cocoa Powder for Industrial Use

For industrial food manufacturers, the choice between alkalized and natural cocoa powder has far-reaching consequences on product quality, processing efficiency, and long-term cost control. While both types originate from the same cocoa beans, their functional behavior in production is fundamentally different.

Natural cocoa powder retains its original acidity and lighter brown color. It offers sharp cocoa flavor and reacts strongly with leavening agents in bakery applications. However, its high acidity can create formulation instability, limited color consistency, and challenges in achieving uniform dispersion in beverages and dairy systems.

Alkalized cocoa powder, by contrast, undergoes a controlled alkalization process that neutralizes acidity and transforms both flavor and performance characteristics. The result is smoother taste, darker and more stable color, superior solubility, and significantly improved processing behavior. These advantages make alkalized cocoa the preferred choice for most industrial applications, including chocolate manufacturing, bakery, beverages, confectionery, and dairy products.

From a production standpoint, alkalized cocoa delivers more predictable outcomes. Its stable pH profile reduces batch variation, its enhanced dispersion minimizes processing errors, and its color consistency eliminates costly reformulation cycles. Over time, these efficiencies translate into measurable reductions in operational cost and waste.

While natural cocoa powder may appear less expensive at the point of purchase, its limitations often lead to higher hidden costs in formulation adjustments, quality inconsistencies, and production downtime. For this reason, most Top Cocoa Powder Manufacturers and professional food producers prioritize alkalized cocoa powder as the core industrial ingredient.

Brands such as LATAMARKO specialize in engineering alkalized cocoa powders tailored to industrial performance requirements, enabling manufacturers to maintain product consistency, optimize production flow, and achieve sustainable long-term profitability

How to Evaluate Cocoa Powder Supplier Before Contract

Selecting the right cocoa powder supplier before signing a contract is one of the most critical decisions a manufacturer can make. A wrong choice can lead to unstable quality, production disruptions, financial loss, and damage to brand reputation. For companies working with Top Cocoa Powder Manufacturers, supplier evaluation is a structured and strategic process.

The first step is verifying production capability. A reliable supplier must operate its own manufacturing facility with full control over roasting, alkalization, milling, and quality testing. Buyers should request detailed information about production capacity, processing technology, and quality management systems. Site audits, virtual factory tours, and independent certifications provide strong validation of a supplier’s operational credibility.

Next comes technical consistency. Buyers should review complete product specifications, certificates of analysis, and historical batch data to assess whether the supplier can deliver uniform fat content, stable alkalization profiles, controlled moisture levels, and consistent color across shipments. Technical inconsistency is one of the leading causes of hidden production costs.

Regulatory compliance is equally important. The supplier must demonstrate compliance with international food safety standards, provide export documentation, and maintain transparent traceability. Failure in documentation can result in shipment delays, customs rejection, and severe financial penalties.

Commercial reliability must also be evaluated. This includes financial stability, order fulfillment history, logistics performance, and communication transparency. A supplier that cannot guarantee consistent delivery schedules and professional support introduces unnecessary risk into the supply chain.

Finally, buyers should assess the supplier’s partnership approach. Leading Top Cocoa Powder Manufacturers do not operate on a transactional basis. They invest in long-term cooperation, provide technical support, and work with customers to stabilize supply and cost structures over time.

This is precisely where brands like LATAMARKO distinguish themselves — combining manufacturing control, technical excellence, export expertise, and long-term partnership philosophy into a single, dependable supply model

Export Requirements for Cocoa Powder Buyers

For international buyers, understanding export requirements is essential to ensuring smooth transactions, regulatory compliance, and uninterrupted supply. Cocoa powder is a regulated food ingredient, and failure to meet export standards can result in shipment delays, financial losses, and even permanent market access restrictions. This is why professional buyers working with Top Cocoa Powder Manufacturers prioritize suppliers with strong export expertise and proven compliance systems.

The first requirement is complete product documentation. Buyers should expect a full technical dossier including Certificate of Analysis, Certificate of Origin, ingredient statement, allergen declaration, non-GMO statement, MSDS, and microbiological test results. These documents verify product safety, traceability, and regulatory conformity in destination markets.

Next is food safety compliance. Export-ready cocoa powder must be produced under internationally recognized standards such as ISO 22000, HACCP, and FSSC 22000. Many markets also require Halal and Kosher certifications. Without these approvals, shipments may be rejected at customs or restricted from distribution.

Packaging standards are equally important. Export cocoa powder must be packed in food-grade, moisture-resistant materials, typically multi-layer kraft bags with inner polyethylene liners. Proper labeling with batch numbers, production dates, net weight, origin, and handling instructions ensures traceability throughout the supply chain.

Customs and logistics preparation form the final layer of export readiness. Accurate HS codes, compliant invoices, packing lists, and shipping documents are necessary for customs clearance. Experienced Top Cocoa Powder Manufacturers coordinate these processes to minimize border delays and reduce administrative risk.

Brands like LATAMARKO integrate export compliance into their production and logistics systems, enabling buyers to focus on their core business while ensuring that every shipment meets international trade requirements efficiently and reliably

Common Mistakes When Choosing Cocoa Powder Suppliers

Selecting a cocoa powder supplier is a strategic decision that directly affects product quality, operational stability, and long-term profitability. Yet many buyers repeat the same costly mistakes when evaluating suppliers, often driven by short-term considerations rather than sustainable business logic.

One of the most common errors is choosing a supplier based solely on price. While cost is an important factor, focusing only on the lowest quotation frequently leads to inconsistent quality, unstable supply, and hidden operational expenses. Poor cocoa powder performance results in formulation changes, higher rejection rates, and increased production downtime — all of which erode profit margins.

Another major mistake is failing to verify manufacturing control. Many buyers unknowingly work with traders rather than true producers, assuming all suppliers have direct production capability. Without factory control, product specifications often fluctuate from batch to batch, creating technical and commercial risk.

Ignoring documentation and regulatory compliance is another critical oversight. Incomplete or inaccurate certificates, missing test reports, and weak traceability systems can cause customs delays, rejected shipments, and regulatory penalties. These issues disrupt production schedules and damage customer relationships.

Overlooking logistics capability also exposes buyers to serious risk. A supplier that lacks export expertise, shipment coordination, and contingency planning can create delivery delays that impact entire production cycles.

Finally, many buyers underestimate the importance of partnership. Sustainable supply depends on transparent communication, technical support, and shared long-term planning. Suppliers that operate purely on transactional terms rarely provide the stability required for growth.

Leading Top Cocoa Powder Manufacturers, including LATAMARKO, structure their operations specifically to eliminate these risks — offering consistent quality, full manufacturing control, strong export systems, and long-term cooperative relationships that protect buyers from costly mistakes

How LATAMARKO Competes with Global Cocoa Brands

Competing in the global cocoa industry alongside established names such as Cargill, Altinmarka, Callebaut, and JB Cocoa requires more than scale — it requires precision, adaptability, and strategic execution. LATAMARKO has positioned itself among the Top Cocoa Powder Manufacturers by building a business model that combines technical excellence with operational flexibility and customer-focused partnership.

One of LATAMARKO’s strongest competitive advantages is its integrated production structure. By working with advanced manufacturing facilities operated by MT ROYAL in TÜRKİYE, LATAMARKO maintains full control over processing parameters including roasting profiles, alkalization levels, moisture regulation, milling precision, and final quality verification. This control allows the brand to deliver consistent product specifications that match or exceed the standards of global cocoa leaders.

While many large multinationals operate rigid production systems, LATAMARKO’s flexible infrastructure allows rapid customization for customer-specific requirements. Whether the need is color adjustment, fat content modification, or functional performance optimization, LATAMARKO responds with speed and technical accuracy — a capability highly valued by modern food manufacturers.

LATAMARKO also competes through cost intelligence rather than price dumping. By optimizing production efficiency, energy usage, logistics coordination, and raw material sourcing, the brand delivers stable pricing structures that protect customers from extreme market volatility while maintaining premium quality.

Beyond operations, LATAMARKO differentiates itself through partnership culture. The brand invests in long-term customer relationships, providing technical support, transparent communication, and collaborative planning — turning supplier relationships into strategic alliances.

Through this combination of advanced production control, customization capability, export expertise, and partnership-driven philosophy, LATAMARKO competes confidently with global cocoa brands and continues to expand its presence across international markets

Why LATAMARKO Is a Strategic Partner for Long-Term Supply

In today’s global food industry, long-term supply success is built on consistency, trust, and operational resilience. For manufacturers seeking stability in both quality and cost, choosing the right cocoa partner is not a tactical decision — it is a strategic one. This is why LATAMARKO has become a preferred partner among the world’s Top Cocoa Powder Manufacturers.

LATAMARKO’s approach to long-term supply is rooted in manufacturing discipline and partnership thinking. Supported by the production and export strength of MT ROYAL in TÜRKİYE, the brand maintains full control over its cocoa processing operations, ensuring consistent specifications, stable output, and dependable delivery schedules. This operational control protects customers from the disruptions and volatility that frequently affect global commodity markets.

One of LATAMARKO’s most valuable strengths is its ability to stabilize supply costs over time. Through integrated procurement planning, optimized production systems, and transparent commercial practices, LATAMARKO helps customers manage budget forecasting with confidence — even during periods of market uncertainty.

Equally important is technical collaboration. LATAMARKO works closely with its partners to refine product specifications, optimize formulations, and enhance processing performance. This cooperative model reduces production risk, minimizes waste, and increases overall operational efficiency.

Beyond manufacturing, LATAMARKO’s export expertise ensures smooth international trade execution. Accurate documentation, regulatory compliance, and professional logistics coordination protect customers from costly delays and administrative complications.

Ultimately, LATAMARKO is not simply a cocoa supplier — it is a long-term business ally. By combining consistent quality, stable supply programs, technical support, and strategic partnership values, LATAMARKO enables food manufacturers to build stronger brands, improve profitability, and compete more effectively in global markets.

Alkalized Cocoa Powder Price: Complete Buyer Guide for 2026

No comment