In today’s fiercely competitive U.S. mining sector, every operational decision echoes through cost structures, production continuity, and long-term profitability. When crushing systems underperform, the ripple effect reaches far beyond the processing line: downtime increases, maintenance budgets swell, and production targets quietly slip out of reach. This is precisely why TÜRKİYE-engineered cone crushers for mining operations in the USA have begun attracting serious attention among plant managers, procurement specialists, and technical directors who are no longer satisfied with legacy solutions.

At MT Royal, we have seen firsthand how American mining operations are re-evaluating their supplier strategies. Instead of automatically defaulting to familiar European or East Asian brands, decision-makers are now looking for equipment that delivers industrial-grade performance, adaptable engineering, and commercial flexibility. Turkish-engineered cone crushers sit squarely at this intersection, offering a balance of robust mechanical design, competitive pricing, and supply-chain resilience that aligns with modern U.S. mining realities.

This article explores why TÜRKİYE-engineered cone crushers are becoming a strategic asset for mining operations across the United States, how they compare with traditional alternatives, and what procurement leaders should understand before integrating them into large-scale production environments.

Understanding Cone Crushers in Modern Mining Operations

Cone crushers play a central role in secondary and tertiary crushing stages. Their purpose is deceptively simple: reduce ore size while maintaining shape consistency and throughput. In practice, however, the engineering behind a high-performance cone crusher determines everything from energy consumption to liner wear rates.

In U.S. mining operations, cone crushers are commonly deployed in:

- Hard rock mining (granite, basalt, quartzite)

- Metal ore processing (copper, gold, iron)

- Aggregate production for infrastructure and construction

What sets a premium cone crusher apart is not just crushing force, but control. Control over particle size distribution, control over wear patterns, and control over maintenance intervals. TÜRKİYE-engineered cone crushers have been designed with this operational control in mind, reflecting decades of experience serving demanding mining environments across Europe, the Middle East, and Central Asia.

Why Türkiye Has Emerged as a Crusher Engineering Hub

Over the past two decades, Türkiye has quietly evolved into a global manufacturing and engineering center for heavy industrial equipment. This transformation did not happen by chance.

Turkish manufacturers benefit from:

- A strong domestic mining and quarrying sector that continuously stress-tests equipment

- Close proximity to European engineering standards without European cost structures

- A workforce experienced in metallurgy, casting, and mechanical design

- Export-driven production models that prioritize adaptability to foreign markets

For U.S. buyers, this means TÜRKİYE-engineered cone crushers are not experimental or unproven. They are the result of iterative engineering improvements shaped by real-world mining conditions.

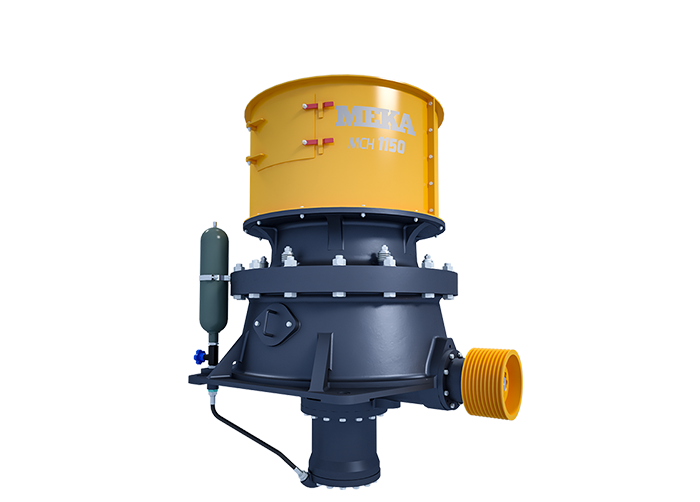

Key Engineering Characteristics of TÜRKİYE-Engineered Cone Crushers

Robust Mechanical Design

Turkish cone crushers are built around reinforced main frames, high-strength alloy steel components, and precision-machined eccentric assemblies. These features directly translate into higher resistance against shock loads and uneven feed conditions—common challenges in U.S. mining operations.

Advanced Liner Geometry

One of the less visible but most impactful advantages lies in liner design. TÜRKİYE-engineered cone crushers often incorporate optimized mantle and concave profiles that improve crushing efficiency while reducing localized wear. The result is longer liner life and more predictable maintenance cycles.

Hydraulic Adjustment and Safety Systems

Modern Turkish cone crushers typically feature hydraulic setting adjustment and tramp release systems. These mechanisms protect the crusher from uncrushable materials and allow operators to fine-tune output without stopping production—a critical advantage in high-throughput U.S. plants.

Energy Efficiency Without Compromise

Energy costs remain a significant concern for mining operators across the USA. Turkish manufacturers have invested heavily in optimizing drive systems and internal kinematics to achieve lower power consumption per ton processed, without sacrificing crushing force.

Common Procurement Mistakes in Industrial Crushing Equipment

Despite the technical sophistication of today’s mining operations, procurement mistakes still occur—often driven by habit rather than analysis.

One common error is overpaying for brand familiarity. While established Western brands offer proven performance, their pricing structures often include legacy costs that do not necessarily translate into operational advantages.

Another frequent mistake is underestimating customization needs. Mining operations in Nevada, Arizona, or Minnesota face vastly different ore characteristics. TÜRKİYE-engineered cone crushers are often more adaptable in configuration, allowing closer alignment with specific geological conditions.

Finally, some buyers focus solely on initial purchase price rather than total cost of ownership. Maintenance intervals, spare part availability, and technical support responsiveness all significantly affect long-term profitability.

How TÜRKİYE-Engineered Cone Crushers Compare with Traditional Alternatives

When evaluated objectively, Turkish cone crushers stand up remarkably well against European and East Asian counterparts.

In terms of mechanical durability, they meet or exceed international standards. In terms of flexibility, they often surpass more rigid legacy designs. And commercially, they offer pricing structures that allow U.S. mining companies to allocate capital more strategically across their operations.

From our experience working with diverse industrial clients, we have observed that operations integrating TÜRKİYE-engineered cone crushers often achieve faster ROI without compromising production stability.

Supply Chain Resilience for U.S. Mining Operations

Recent disruptions in global logistics have forced American manufacturers to rethink supplier concentration. Relying on a single region for critical equipment now represents a tangible operational risk.

Türkiye’s geographic position and export infrastructure provide a valuable alternative supply route. Lead times are often shorter than East Asian shipments, and spare parts availability tends to be more responsive than heavily centralized European supply chains.

At MT Royal, we position ourselves not just as a distributor, but as a coordination point between U.S. mining operations and multiple Turkish manufacturers. This diversified sourcing model reduces dependency risks while preserving technical consistency.

Industrial-Scale Performance: What Matters in High-Volume Mining

For large-scale mining operations, theoretical performance metrics matter less than real-world stability. TÜRKİYE-engineered cone crushers have demonstrated strong performance in continuous operation environments, where uptime and predictability outweigh marginal efficiency gains.

Key advantages for high-volume production include:

- Stable throughput under variable feed conditions

- Lower vibration transmission to surrounding structures

- Predictable wear progression, simplifying maintenance planning

- Compatibility with automated monitoring systems

These factors directly influence annual production targets and operational budgeting—areas where U.S. mining executives demand clarity rather than optimism.

Frequently Asked Questions from U.S. Mining Managers

Are TÜRKİYE-engineered cone crushers compliant with U.S. standards?

Yes. Most reputable Turkish manufacturers design their equipment to comply with international safety and engineering standards applicable in the USA. Proper documentation and certification are typically available through authorized suppliers.

How do spare parts availability and lead times compare?

In many cases, spare parts lead times are competitive or even shorter than those of legacy suppliers, particularly when coordinated through established distributors like MT Royal.

Can these crushers integrate with existing processing lines?

Absolutely. Turkish cone crushers are commonly configured to integrate seamlessly with existing conveyors, screens, and control systems used in U.S. plants.

Is technical support accessible for U.S. operations?

With the right supply partner, technical support and documentation are readily accessible. We have seen that proactive supplier coordination significantly reduces commissioning and troubleshooting timelines.

The Role of MT Royal in Strategic Equipment Sourcing

MT Royal operates at the intersection of engineering understanding and commercial pragmatism. Rather than pushing a single brand, we work with multiple TÜRKİYE-engineered cone crusher manufacturers to match technical specifications with operational realities.

We have learned through collaboration with factories and mining operations that trust is built not through promises, but through consistency—consistent quality, consistent delivery, and consistent post-supply support. This approach allows us to serve as a reliable sourcing partner for U.S. mining companies seeking alternatives without uncertainty.

Looking Ahead: A Calculated Evolution in Crushing Strategy

The growing adoption of TÜRKİYE-engineered cone crushers for mining operations in the USA is not a passing trend. It reflects a deeper shift toward diversified sourcing, engineering-driven procurement, and long-term cost control.

Mining operations that remain locked into outdated supplier assumptions risk paying more for less flexibility. Those willing to evaluate Turkish-engineered solutions with an open, analytical mindset often discover that performance, reliability, and commercial logic do not have to be mutually exclusive.

The next generation of U.S. mining success will belong to operators who treat equipment sourcing as a strategic decision rather than a routine transaction. In that context, TÜRKİYE-engineered cone crushers are not merely an alternative—they are a competitive instrument.

No comment